Polarizer capable of realizing high polarization extinction ratio, manufacturing method and testing device thereof

A polarization extinction ratio and testing device technology, which is applied in polarizing components, testing optical properties, optics, etc., can solve the problems of low measurement upper limit and inability to meet the requirements of accurate measurement of polarization extinction ratio, so as to improve performance and increase the measurement upper limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

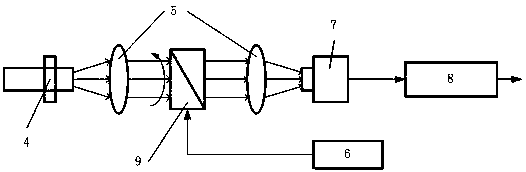

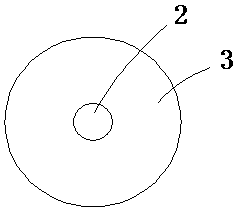

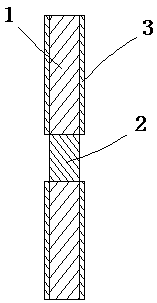

[0027] A polarizer capable of achieving a high polarization extinction ratio, the innovation of which is: the substrate of the polarizer is a lithium niobate wafer 1 cut from a lithium niobate crystal; the lithium niobate wafer 1 is a sheet structure The middle part of the lithium niobate wafer 1 is provided with a columnar optical waveguide region 2, the axial direction of the optical waveguide region 2 is perpendicular to the large plane of the lithium niobate wafer 1, and the optical waveguide region 2 runs through the lithium niobate wafer 1; the lithium niobate wafer The area other than the optical waveguide area 2 on the large plane of 1 is covered with a light-blocking film layer 3; the diameter of the optical waveguide area 2 is 4 to 100mm; the large plane of the lithium niobate wafer 1 is tangential to or X-Z tangentially parallel.

[0028] Further, the cross-section of the optical waveguide region 2 is circular, the diameter of the optical waveguide region 2 is 4-100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com