Installation structure with hinge towards plug socket

A technology of installation structure and socket, which is applied in the direction of telephone structure, electrical equipment structure parts, pivot connection, etc., can solve the problems that the structure cannot be adopted, and achieve the effect of easy insertion, rotation prevention and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

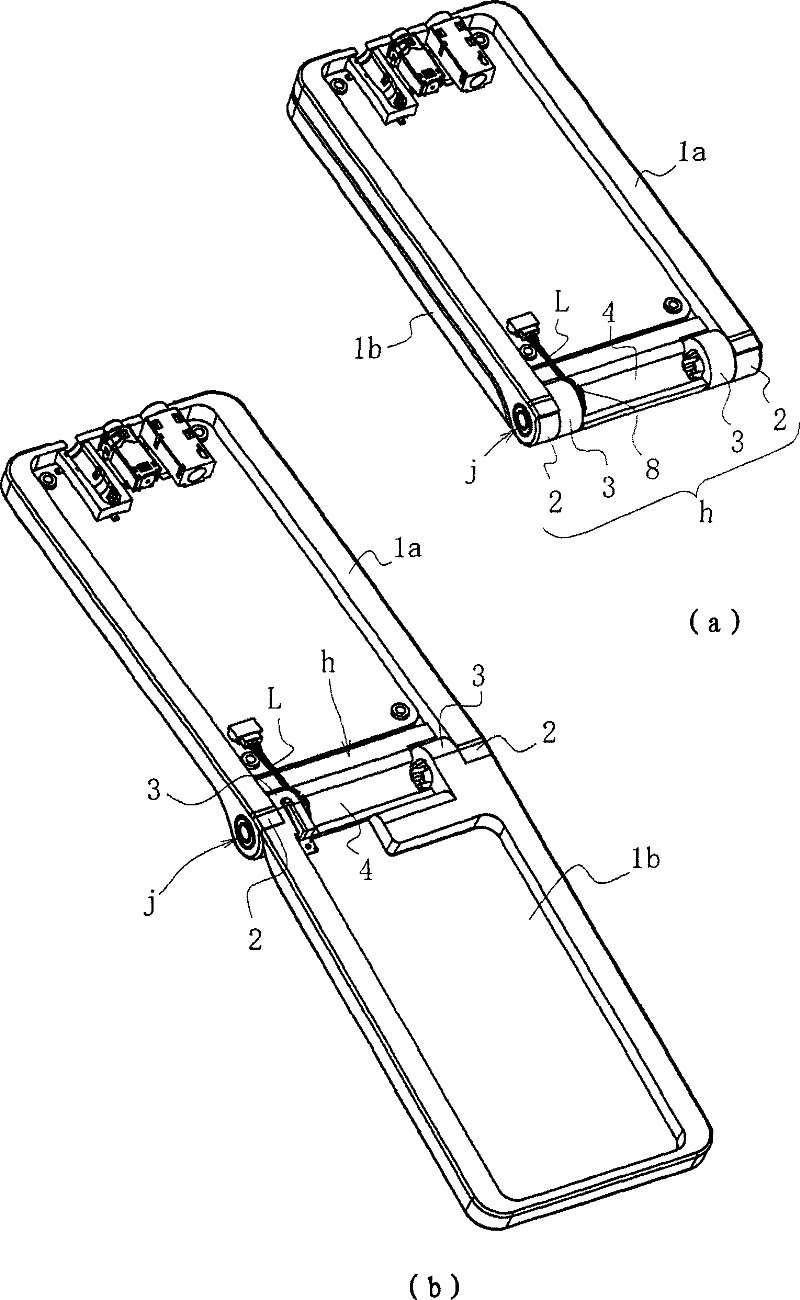

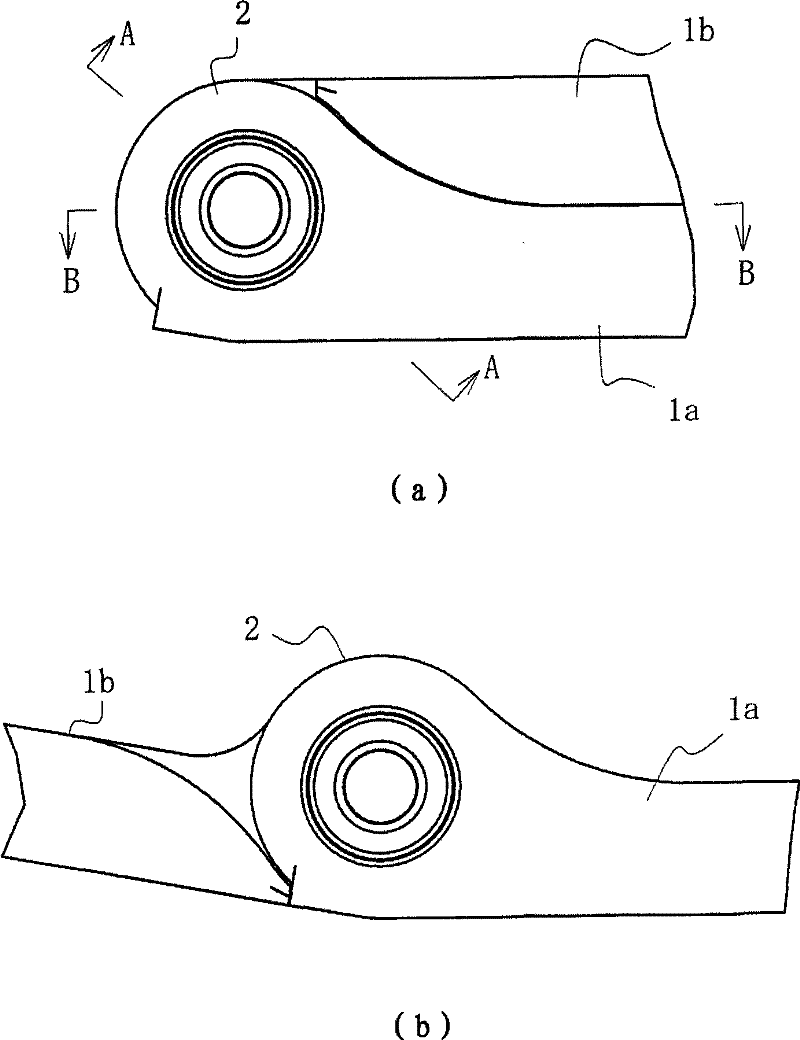

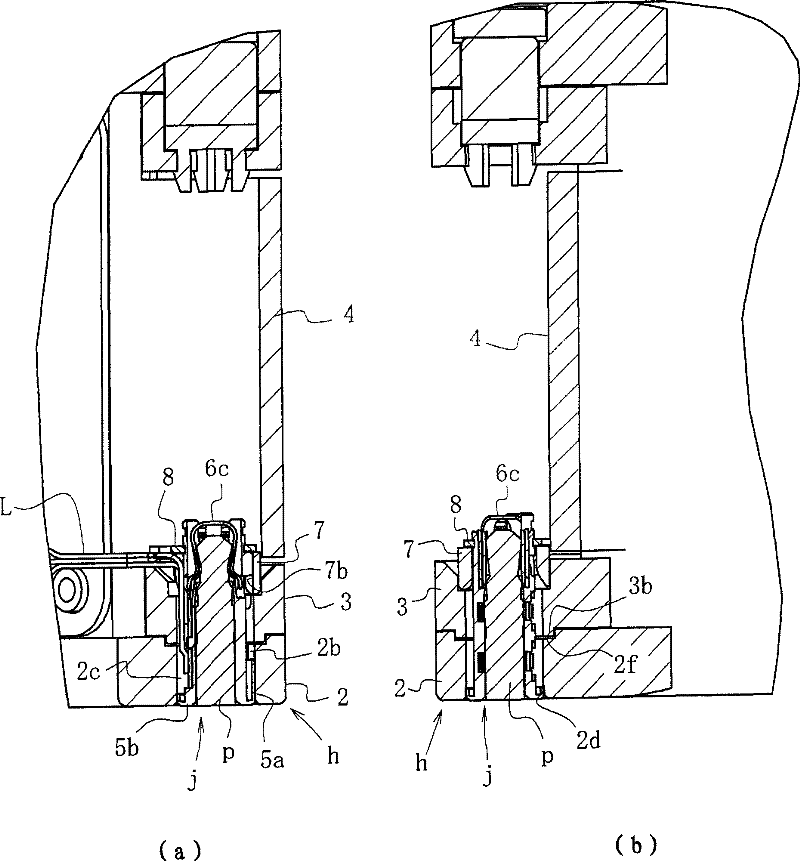

[0044] The installation structure of the socket of the present embodiment to the hinge part is basically as follows: image 3 , Figure 4 and Figure 5 Shown is a mounting structure of a socket j inserted and arranged in a hinge tube of a hinge portion h that foldably couples two arms 1a, 1b of a mobile phone terminal.

[0045] A socket j to be installed is inserted into the fixed hinge pipe 2 at the end of the above-mentioned hinge part h and the movable hinge pipe 3 inside it. and a push-in restricting mechanism as a part of the axial movement preventing mechanism of the socket j and a push-in restricting mechanism as a part of the axial movement preventing mechanism of the socket j and the movable hinge pipe 3 as the Another part of the axial movement preventing mechanism is a pull-out restricting mechanism, and a rotation securing mechanism that ensures the latter's free rotation around their axes is formed between the above-mentioned fixed hinge pipe 2 and the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com