Differential operation device of straddle-type single-track vehicle

A straddle-type monorail and running device technology, which is applied in the direction of railway vehicles, transportation and packaging, and transmission devices driven by electric motors, can solve problems such as tire wear, unfavorable stable and safe operation of vehicles, and lack of differential adjustment functions. Achieve the effect of reducing wear and improving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

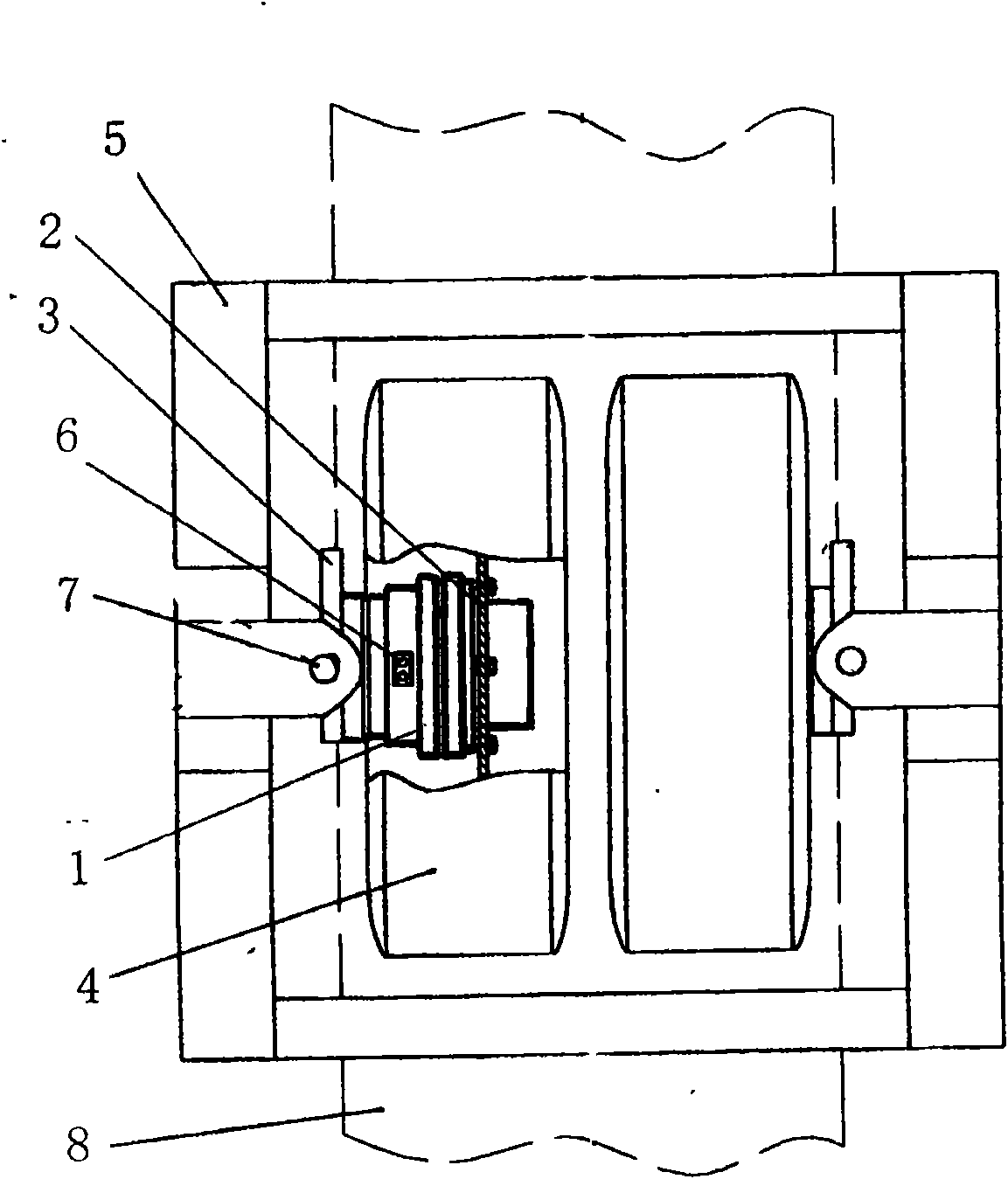

[0011] Shown in the accompanying drawings embodiment: for the vehicle running on the light rail PC beam 8, its two left and right side-by-side running wheels 4 are respectively equipped with a wheel side motor and a brake 1 on its wheel hub 2, a wheel side motor and a brake 1 is provided with a high-pressure oil interface 6 that can be connected to the vehicle hydraulic system, and the flange 3 on the outside of the wheel motor and brake 1 is hinged to the bogie 5 below the vehicle with a steering pin 7.

[0012] During implementation, the high-pressure oil interface 6 is connected with the driving hydraulic system through oil pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com