Super-cooling nickel base high-temperature alloy purifying agent and preparation method thereof

A technology of nickel-based superalloy and purifying agent, which is applied in the fields of metal materials and metallurgy, and achieves the effects of simple operation process, low price and convenient addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

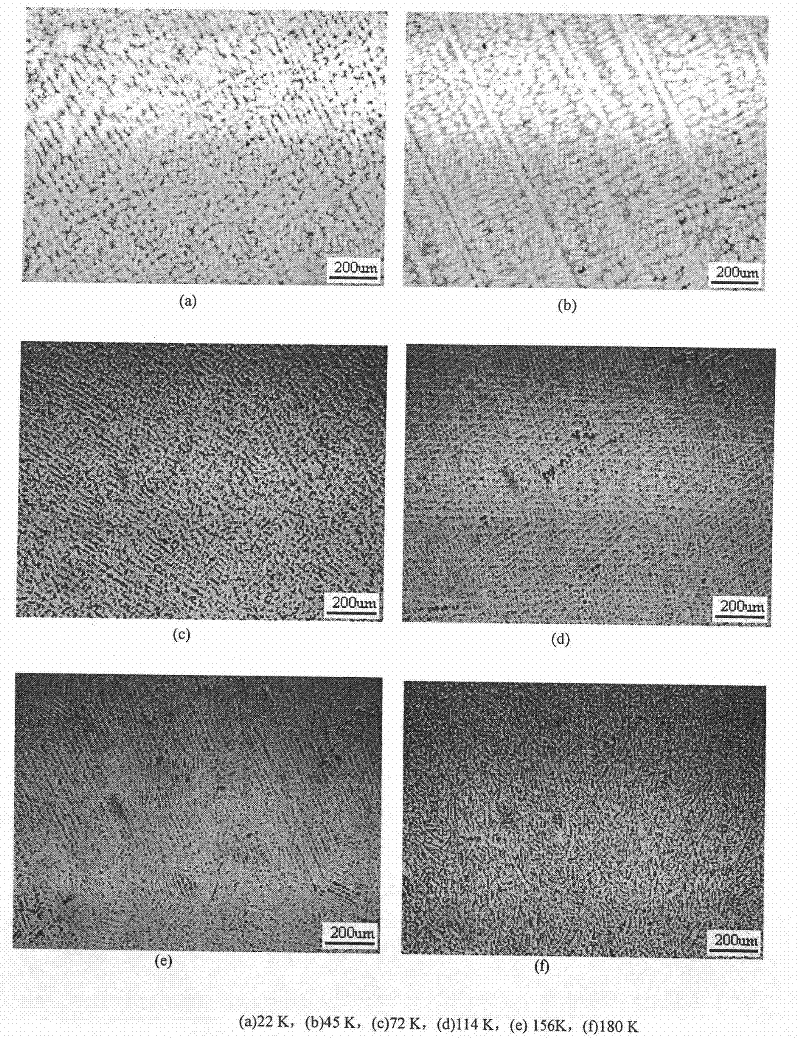

Image

Examples

Embodiment 1

[0022] Composite molten salt purifier composition (mass percentage): 40% calcium fluoride (CaF 2 ), 30% aluminum fluoride (AlF 3 ), 15% cryolite (Na 3 AlF 6 ), 5% sodium chloride (NaCl), 5% potassium chloride (KCl), 4% calcium oxide (CaO), the rare earth compound is LaCl 3 , the amount added is 1%.

[0023] The production method of the high-temperature alloy purifying agent is as follows: according to the above ratio, put the weighed potassium chloride, sodium chloride, cryolite, calcium fluoride, aluminum fluoride and calcium oxide in a crucible and stir evenly, and heat up to 1050- 1100°C and keep it warm for 3-4 hours to ensure uniform sintering. Then crush the sintered massive molten salt, put it into a ball mill, grind it into powder, and sieve it with a No. 20-40 sieve. Then add the rare earth compound LaCl 3 , and use a ball mill to mix evenly, and put the prepared purifying agent into the desiccator for later use.

[0024] The deep supercooling solidification ex...

Embodiment 2

[0026] Composite molten salt purifier composition (mass percentage): 50% calcium fluoride (CaF 2 ), 16% aluminum fluoride (AlF 3 ), 10% cryolite (Na 3 AlF 6 ), 8% sodium chloride (NaCl), 8% potassium chloride (KCl), 6% calcium oxide (CaO), the rare earth compound is LaCl 3 , the amount added is 2%.

[0027]The production method of the high-temperature alloy purifying agent is as follows: according to the above ratio, put the weighed potassium chloride, sodium chloride, cryolite, calcium fluoride, aluminum fluoride and calcium oxide in a crucible and stir evenly, and heat up to 1050- 1100°C and keep it warm for 3-4 hours to ensure uniform sintering. Then crush the sintered massive molten salt, put it into a ball mill, grind it into powder, and sieve it with a No. 20-40 sieve. Then add the rare earth compound LaCl 3 , and use a ball mill to mix evenly, and put the prepared purifying agent into the desiccator for later use.

[0028] The deep supercooling solidification exp...

Embodiment 3

[0030] Composite molten salt purifier composition (mass percentage): 45% calcium fluoride (CaF 2 ), 24% aluminum fluoride (AlF 3 ), 12% cryolite (Na 3 AlF 6 ), 7% sodium chloride (NaCl), 7% potassium chloride (KCl), 4% calcium oxide (CaO), the rare earth compound is CeCl 3 , the amount added is 1%.

[0031] The production method of the high-temperature alloy purifying agent is as follows: according to the above ratio, put the weighed potassium chloride, sodium chloride, cryolite, calcium fluoride, aluminum fluoride and calcium oxide in a crucible and stir evenly, and heat up to 1050- 1100°C and keep it warm for 3-4 hours to ensure uniform sintering. Then crush the sintered massive molten salt, put it into a ball mill, grind it into powder, and sieve it with a No. 20-40 sieve. Then add the rare earth compound CeCl 3 , and use a ball mill to mix evenly, and put the prepared purifying agent into the desiccator for later use.

[0032] The deep supercooling solidification ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com