Patents

Literature

40 results about "POTASSIUM CHLORIDE/SODIUM CHLORIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium Chloride in 0.9% Sodium Chloride Injection is contraindicated in clinical conditions where additives of sodium, potassium or chloride could be clinically detrimental.

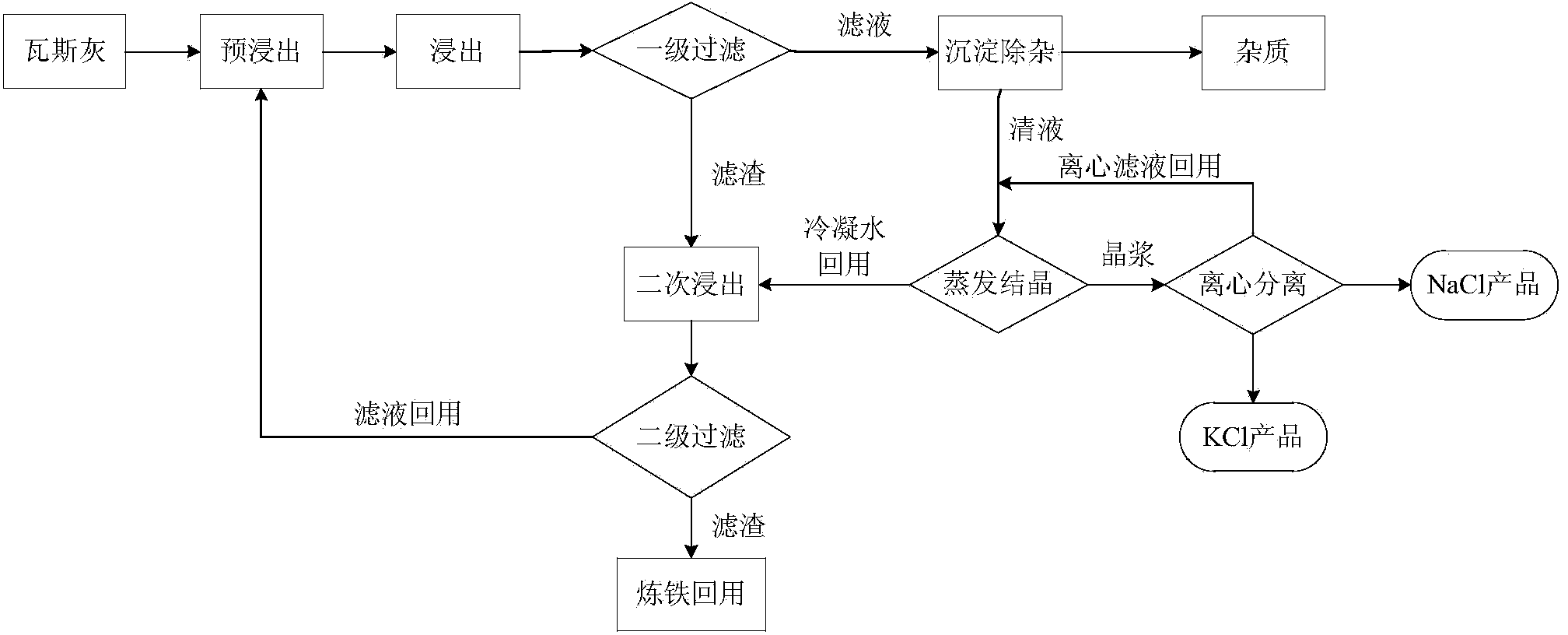

Method for producing potassium chloride by using blast furnace dust of iron and steel enterprises

ActiveCN103435073AHarm reductionQuality improvementAlkali metal chloridesProcess engineeringEnvironmental engineering

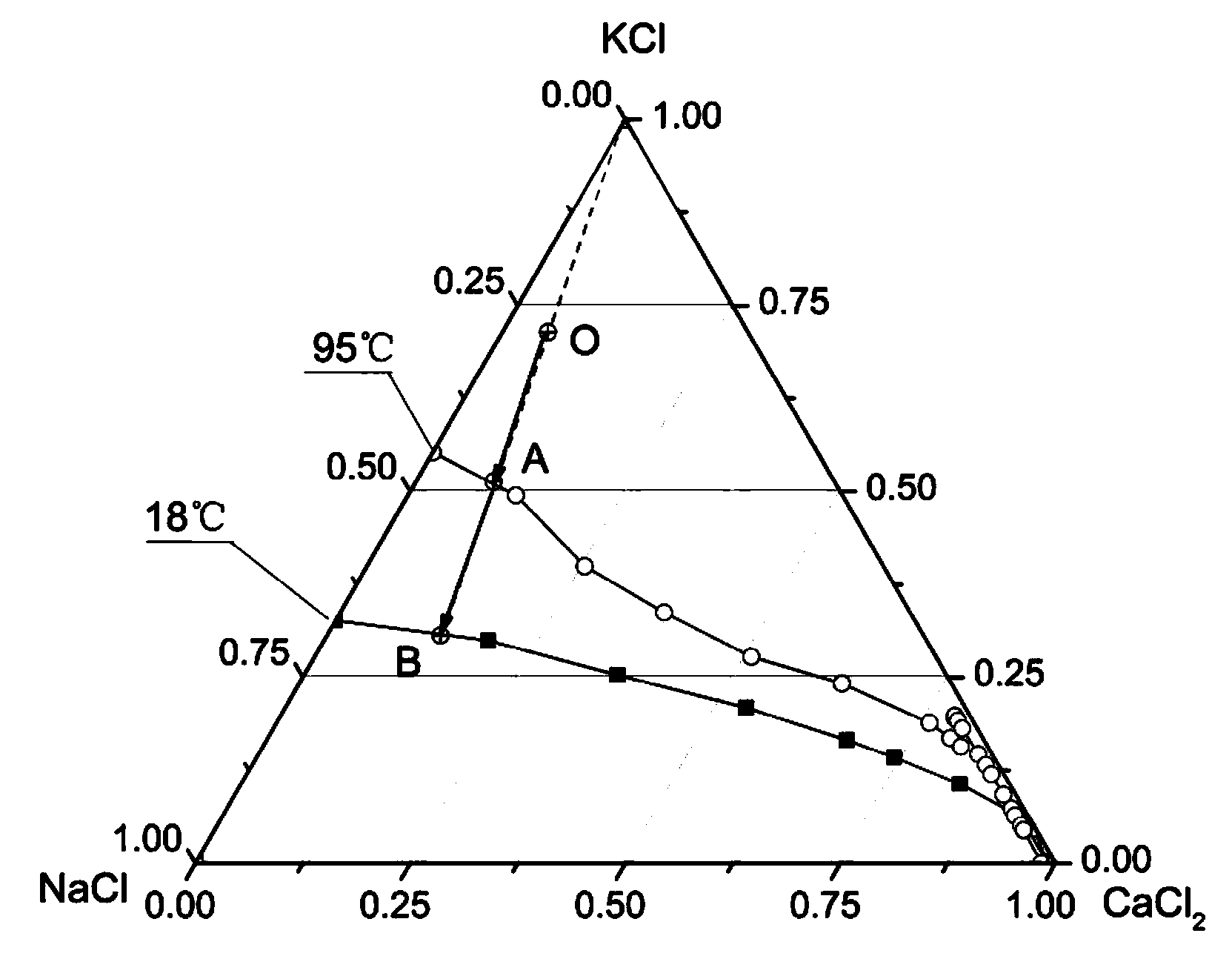

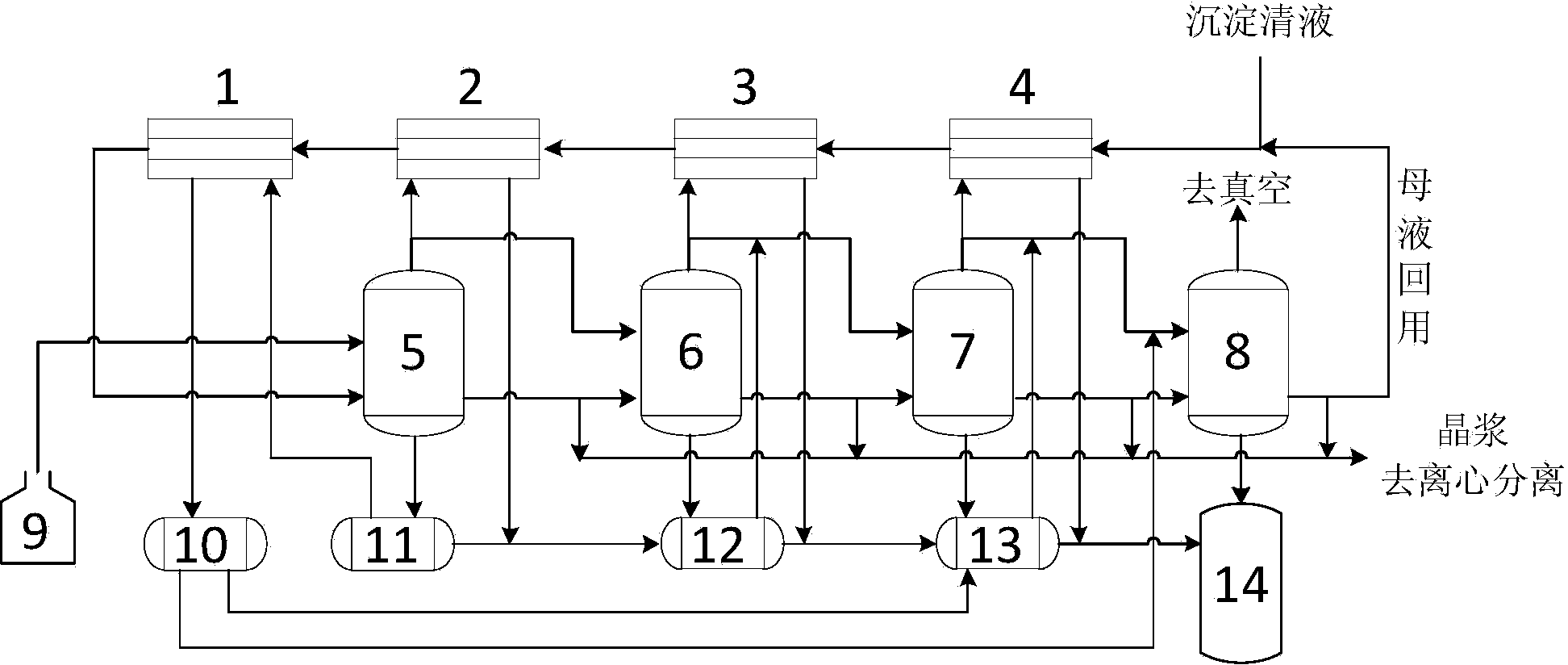

The invention discloses a method for producing potassium chloride by using blast furnace dust of iron and steel enterprises. The method comprises the following steps: mixing the blast furnace dust with running water according to a certain ratio in a pre-leaching process; at the end of the mixing, stirring and leaching the mixed solution in a leaching process; filtering the mixed solution in a primary filtering procedure; removing impurities out of primary filtrate in a precipitating and impurity removing procedure; leaching the primary filter residue for the second time in a secondary leaching procedure; adding a precipitator to the primary filtrate in the precipitating procedure for precipitate and removing impurities; standing still for layering or filtering after completely precipitating; carry out multi-effect crystallization on clear liquid in an evaporation crystallization process to produce potassium chloride and sodium chloride products; filtering the mixed solution to secondary filtering equipment after the secondary leaching procedure reaches the filter condition; and recycling secondary filter residue for making iron, and returning the secondary filtrate to the pre-leaching process to be used again. By adopting the method, the high potassium feature in the blast furnace dust is fully utilized, waste materials are changed into valuable resources, the damage of emission of waste to the environment is reduced, and a high-quality potassium chloride product is also produced.

Owner:UNIV OF SCI & TECH BEIJING

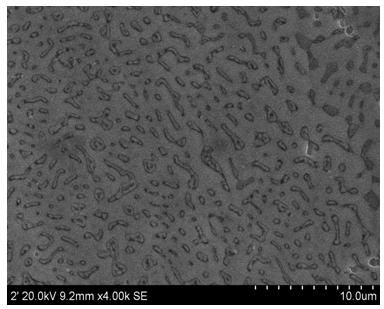

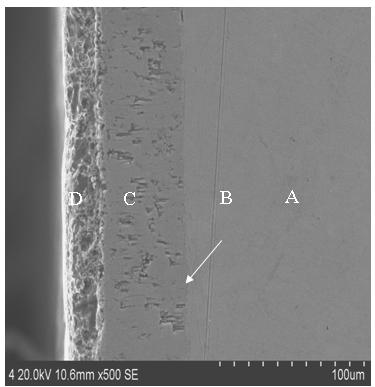

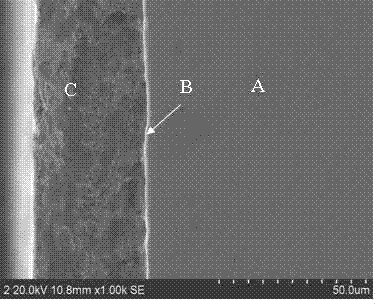

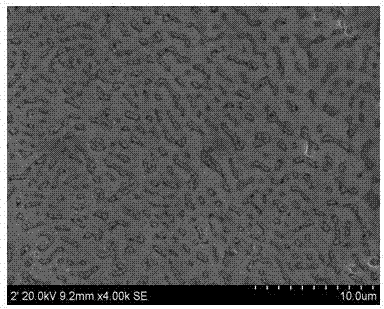

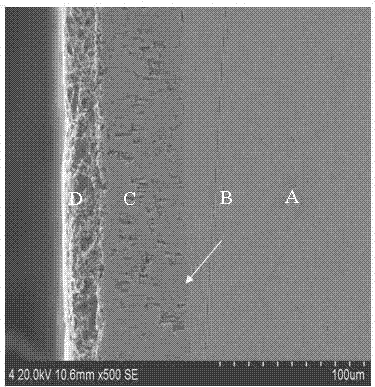

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990AEasy to dryImprove protectionHot-dipping/immersion processesElectrolysisEthylic acid

The invention relates to electrolytic plating assistant for hot dip galvanizing of a steel wire. Electrolytic plating assistant comprises the following components: 30-220 g / L of zinc chloride, 0-150 g / L of potassium chloride, 0-150 g / L of sodium chloride, 2-90 g / L of ammonium chloride, 0-100 g / L of boric acid, 0-70 g / L of acetic acid, 1-25 g / L of sodium fluoride, 2-50 g / L of cerium chloride, 0-50 g / L of potassium fluozirconate, 0-50 g / L of methanol, 0.5-20 g / L of hydrogen peroxide and the balance of water. The electrolytic plating assisting method comprises the following steps: washing with alkali, removing oil, washing with water, washing with acid to remove rust, washing with water, activating with weak acid, electrolyzing to assist plating, drying, and purifying the electrolytic plating assistant. The method can reduce the generation of AlCl3, prevent skip plating and reduce the generation of smoke dust. The electrolytic plating assistant has the characteristic of relatively high melting point, and thus, can increase the drying temperature and shorten the drying time. The dried plating assistant has the characteristics of low brittleness, high compatibility with electrogalvanizing, and low tendency to shedding.

Owner:NORTHEASTERN UNIV

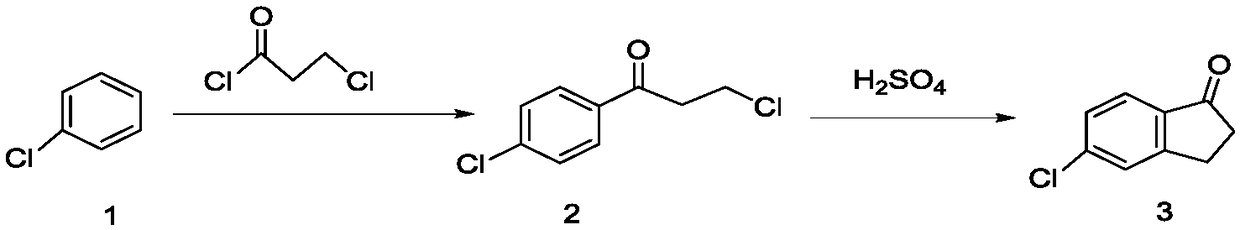

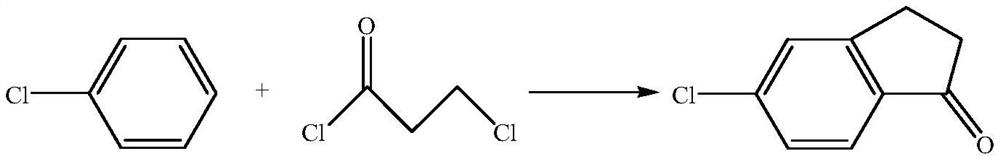

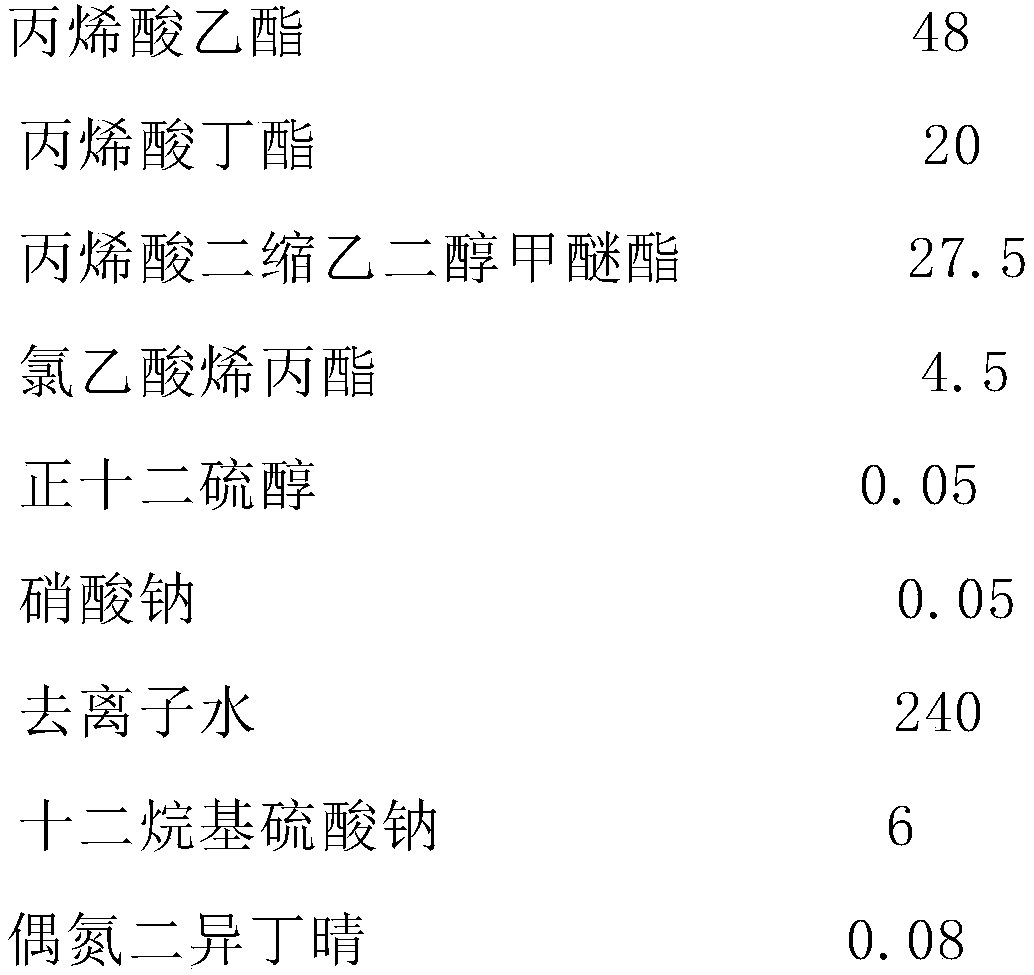

5-chloro-2,3-dihydro-1-indanone preparation method

ActiveCN109293488ASolve the problem of sublimation before meltingOvercoming Pollution DisadvantagesCarbonyl compound preparation by condensationAluminium chlorideChlorobenzene

The invention provides a 5-chloro-2,3-dihydro-1-indanone preparation method, which comprises: carrying out a reaction by using chlorobenzene and 3-chloro-propionyl chloride as raw materials and usinga mixed molten salt as catalyst and a solvent to obtain 5-chloro-2,3-dihydro-1-indanone, wherein the mixed molten salt is a mixture comprising any two or three materials selected from potassium chloride, sodium chloride and aluminum chloride. According to the present invention, the mixed molten salt potassium chloride-sodium chloride-aluminum chloride is used as the catalyst, and becomes liquid ata temperature of about 100 DEG C, such that the problem that aluminum chloride is sublimated before melting is solved; and the mixed molten salt potassium chloride-sodium chloride-aluminum chloride is simultaneously used as the catalyst and the solvent in the reaction of chlorobenzene and 3-chloro-propionyl chloride, such that the conversion rate of the reaction can achieve 98% at the temperatureof 120-130 DEG C, and the yield of 5-chloro indanone can achieve 75%.

Owner:四平市精细化学品有限公司

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990BAvoid secondary oxidationEasy to dryHot-dipping/immersion processesElectrolysisEthylic acid

Owner:NORTHEASTERN UNIV LIAONING

Quenching method of 45# steel workpiece

The invention provides a quenching method of a 45# steel workpiece. The quenching method comprises the following steps of: heating the workpiece to 880 DEG C-890 DEG C in a heating device, and preserving the heat for 1 hour-2 hours; quenching by using a quenching agent with temperature of 100 DEG C-120 DEG C, and tempering at 500 DEG C-510 DEG C, wherein the quenching agent consists of the following substances in percentage by mass: 5%-6% of potassium chloride, 1%-2% of sodium chloride and the balance of water. The 45# steel made by using the quenching method disclosed by the invention cannot crack during quenching.

Owner:珠海市顺志机械制造有限公司

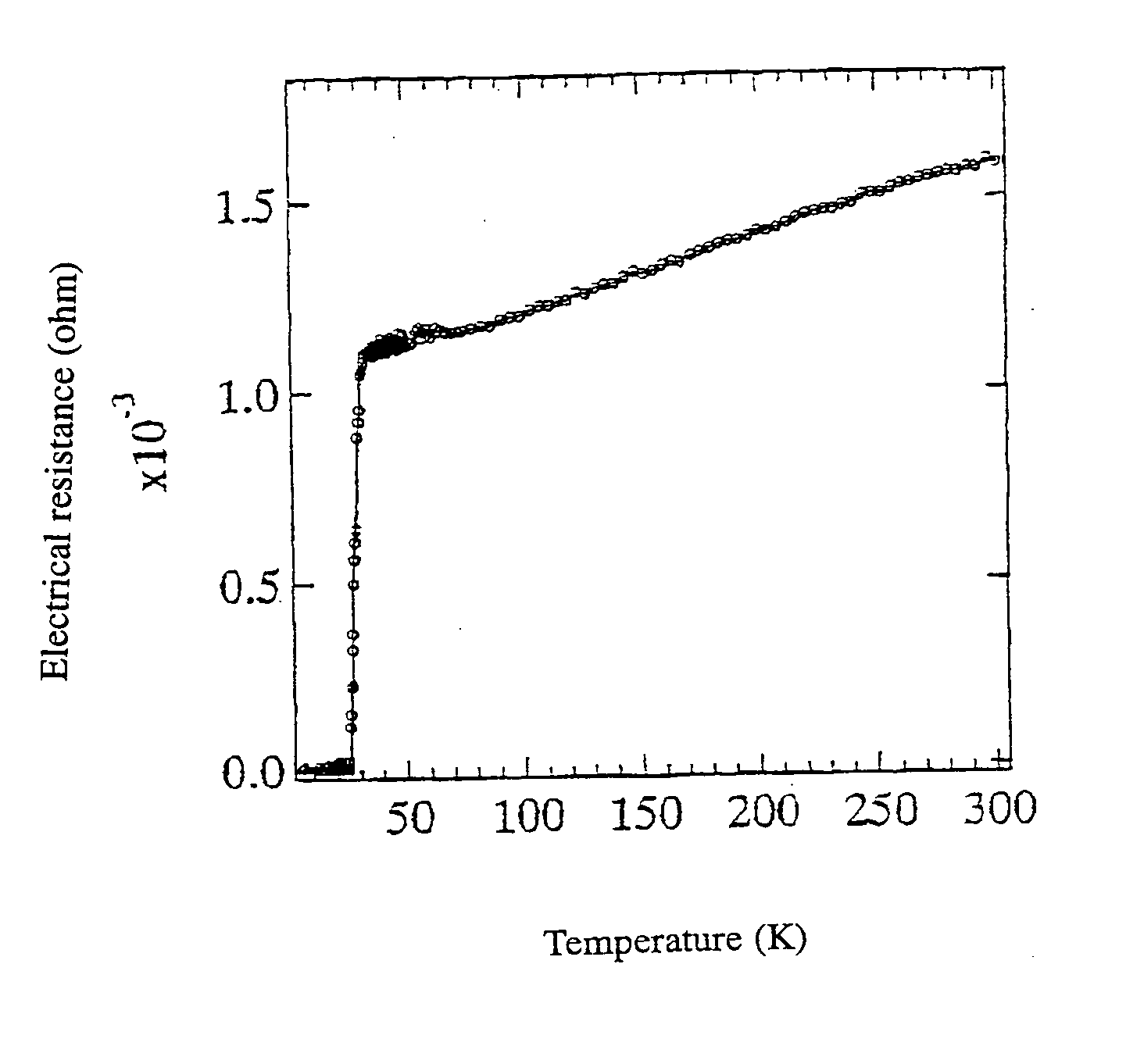

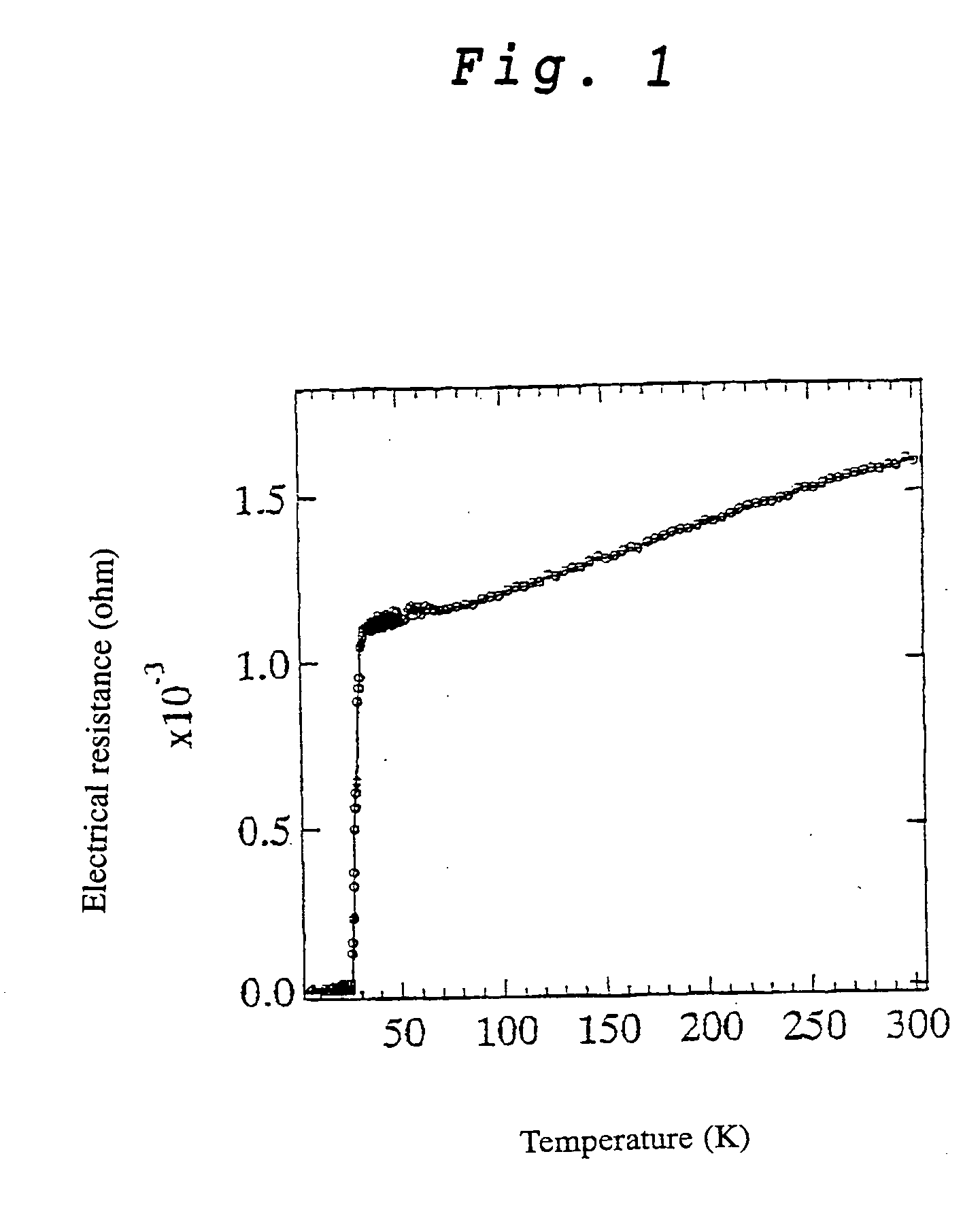

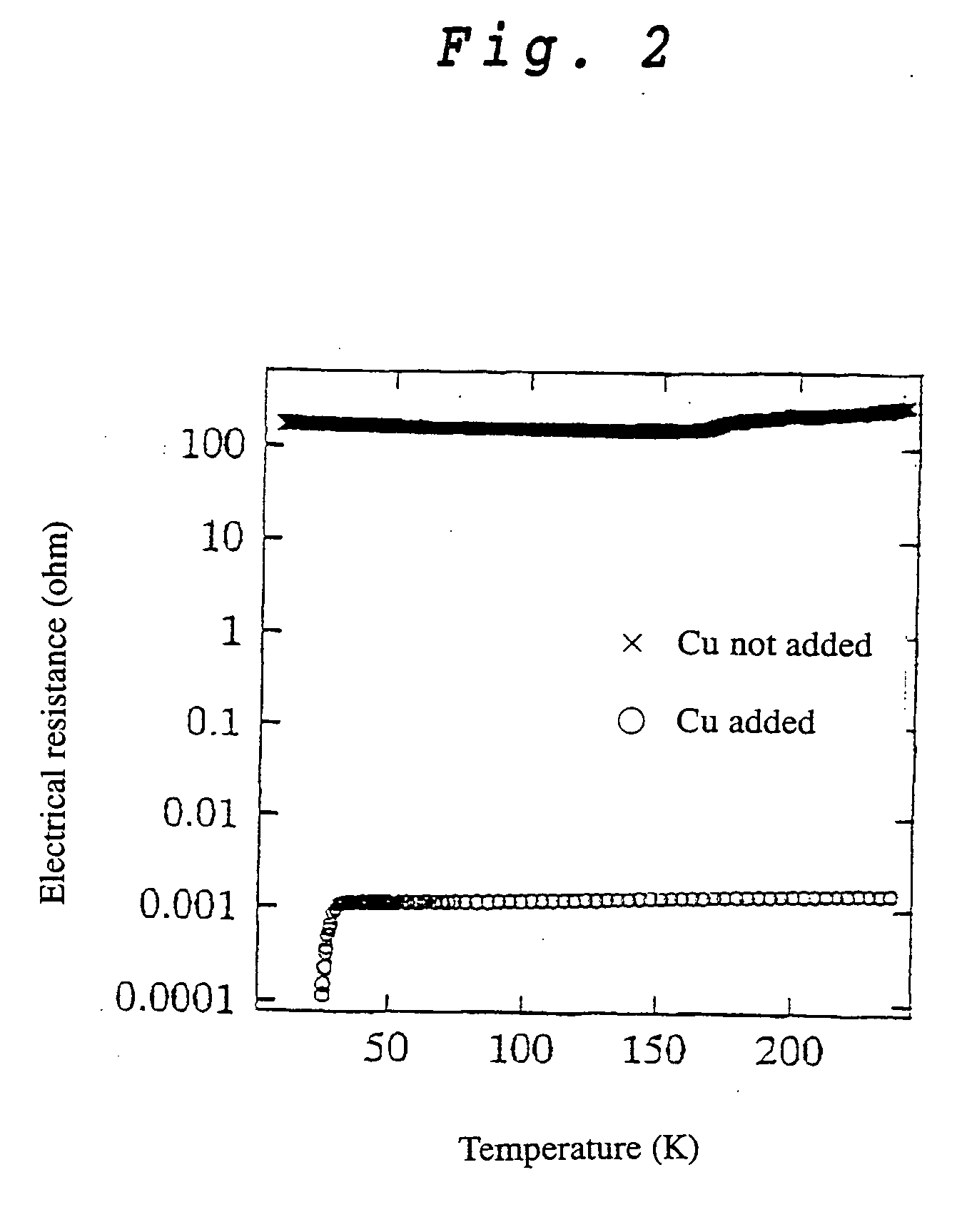

Method of manufacturing MgB2 superconducting material

InactiveUS20050034992A1Improve superconductivityElectrolytic coatingsDuplicating/marking methodsMetallic materialsMaterials science

A very small amount of copper chloride or zinc oxide is added to a mixture of magnesium chloride, potassium chloride, sodium chloride and magnesium borate, a mixed salt is melted under heat, electrodes are inserted into a molten salt and a metallic material employed as a cathode is electroplated with a magnesium diboride (MgB2) film.

Owner:JAPAN ATOM ENERGY RES INST

Chloride type trivalent chromium black chromium plating solution

The invention discloses a chloride type trivalent chromium black chromium plating solution which comprises the following components by weight: 30 to 70g / L of chromium trichloride, 150-320g / L of conducting salt, 20 to 70g / L of complexing agent, 2 to 10g / L of blackening agent, and 0.2 to 1g / L of surfactant, wherein the conducting salt is one of or a mixture of potassium chloride, sodium chloride, ammonia chloride, sodium sulfate and potassium sulfate; the complexing agent is one of or a mixture of ammonium oxalate, malic acid and formic acid; and the blackening agent is one of or a mixture of ferric chloride, potassium thiocyanate, ammonium thiocyanate and cobalt nitrate. According to the chloride type trivalent chromium black chromium plating solution, a trivalent black chromium plating layer with thickness being 0.2 to 0.5microns can be obtained, an appearance of the plating layer is uniform and bright black, and the colors of a high electric current density region and a low electric current density region are essentially identical; and the chloride type trivalent chromium black chromium plating solution does not yellow or change color even if being placed in air in a plum rain season, and the mildews can not be found.

Owner:NANJING DADI REFRIGERATION FOOD

Preparation method of 5-chloro-1-indanone

ActiveCN112457179AReduce dosageReduce pollutionOrganic compound preparationCarbonyl compound preparation by condensationAluminium chlorideChlorobenzene

The invention provides a preparation method of 5-chloro-1-indanone, and belongs to the technical field of organic synthesis. Chlorobenzene and 3-chloropropionyl chloride are used as raw materials, mixed molten salt and heteropolyacid are used as catalysts, and heating reaction is performed to obtain 5-chloro-1-ndanone, wherein the heteropolyacid is SiO2 loaded phosphotungstic acid, and the mixed molten salt is a mixture of any two or three of potassium chloride, sodium chloride and aluminum chloride. By controlling the feeding temperature and the feeding sequence, the reaction is carried out at a lower temperature, the problems of large solid amount, high temperature, violent reaction, large tar amount, carbonization of raw materials, more three wastes and the like when aluminum trichloride is used as a catalyst are avoided, and the yield of 5-chloro-1-indanone can reach up to 85%.

Owner:FUXIN RUIGUANG FLUORINE CHEM

Method for producing ytterbium-doped lithium nickel cobalt manganese oxide material used for lithium ion battery

ActiveCN106257715ALoose tube wallAlleviate volume expansionCell electrodesSodium-ion batteryManganese oxide

Owner:ZHEJIANG CHANGXING KISUN POWER SUPPLY

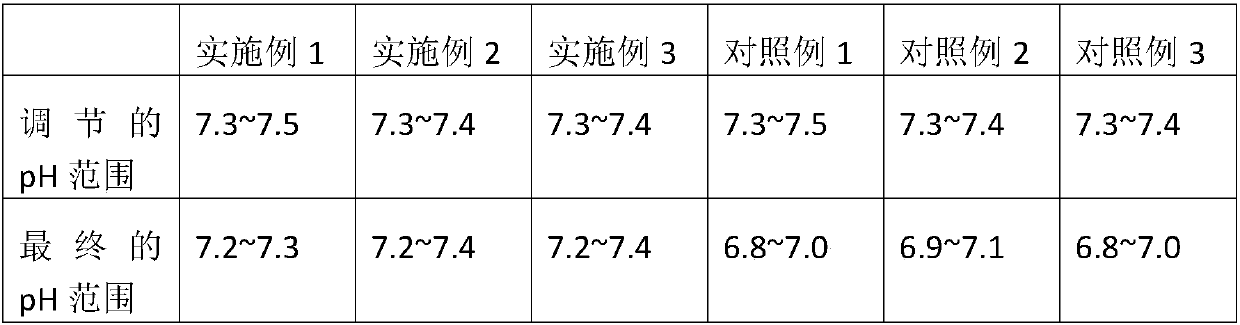

Composite electrolyte injection

InactiveCN107753505AWill not increase the burdenThe preparation method is simple and easyInorganic non-active ingredientsPharmaceutical delivery mechanismAcetic acidComposite electrolyte

The invention provides a composite electrolyte injection with a buffer agent and relates to the field of chemical medicines. Every 100ml of the injection comprises 0.037g of potassium chloride, 0.53gof sodium chloride, 0.5g of sodium gluconate, 0.03g of magnesium chloride, 1.5-1.2g of glucose, 0.8-1.2g of fructo-oligose, a pH value buffer agent and a pH value adjusting agent, wherein the pH valuebuffer agent is acetate and is preferably selected from sodium hydrogen phosphate (heptahydrate) and monopotassium phosphate; the concentration of the sodium hydrogen phosphate (heptahydrate) is 0.1-0.2g / L; the concentration of the monopotassium phosphate is 8.0-9.0mg / L; and the pH value adjusting agent is at least one of glacial acetic acid and sodium hydroxide. The composite electrolyte injection has the beneficial effects that saccharides are replenished, intestinal flora are regulated, patients in transfusion are prevented from constipation, no extra burden is caused, the pH value of theinjection is maintained within 7.0-7.8, and pH value adjusting procedures of the injection are simplified.

Owner:HUAREN PHARMACEUTICAL CO LTD

-28 DEG C phase change coolant and preparation method thereof

InactiveCN110835521ASolve the problem of low freezing efficiencyFast heat conductionHeat-exchange elementsCelluloseCarboxymethyl cellulose

The invention discloses a -28 DEG C phase change coolant and a preparation method thereof. The -28 DEG C phase change coolant comprises, by mass, 10-15% of potassium chloride, 5-10% of sodium chloride, 8-15% of ammonium chloride, 0.2-1% of sodium carboxymethyl cellulose, 0.1-1.5% of a nanoscale metal material compound A, and the balance of deionized water. The crystallization temperature of the -28 DEG C phase change coolant is -30 to-26 DEG C, the phase change latent heat can reach 230 kJ / kg, and the phase change coolant is safe, nontoxic and cheap, and can be used as a refrigerant to meet the freezing requirements of frozen medicines, meat and seafood.

Owner:上海直帆冷链技术有限公司

Preparation method for holmium-doped lithium nickelate material for lithium ion battery

ActiveCN106299349ALower melting temperatureImprove diffusivityCell electrodesSecondary cellsCharge dischargeLithium-ion battery

The invention discloses a preparation method for a holmium-doped lithium nickelate material for a lithium ion battery. The preparation method comprises the following steps of a), weighing materials base on stoichiometric ratio; b), adding absolute ethyl alcohol to a raw material, and performing ball milling and drying; c), adding acetate fibre, potassium chloride and sodium chloride mixed fused salt, and absolute ethyl alcohol to the raw material prepared in the step b, and performing ball milling and drying; and d), sintering the raw materials processed in the step c, then cooling after completing sintering, and next, cleaning by clean water and drying to obtain the holmium-doped lithium nickelate material. The holmium-doped lithium nickelate material for the lithium ion battery has higher discharge capacity and capacity per gram; the holmium-doped lithium nickelate material adopts a hollow tubular structure; after the holmium-doped lithium nickelate material is further processed, the tube wall is more loosened, so that the volume expansion in the charge-discharge process can be relieved; and in addition, inorganic filler, which refers to titanium dioxide, in the acetate fibre is doped into crystal lattices of the holmium-doped lithium nickelate material so as to improve the stability of the holmium-doped lithium nickelate material and reduce the capacity attenuation problem of the lithium ion battery.

Owner:浙江旭派动力科技有限公司

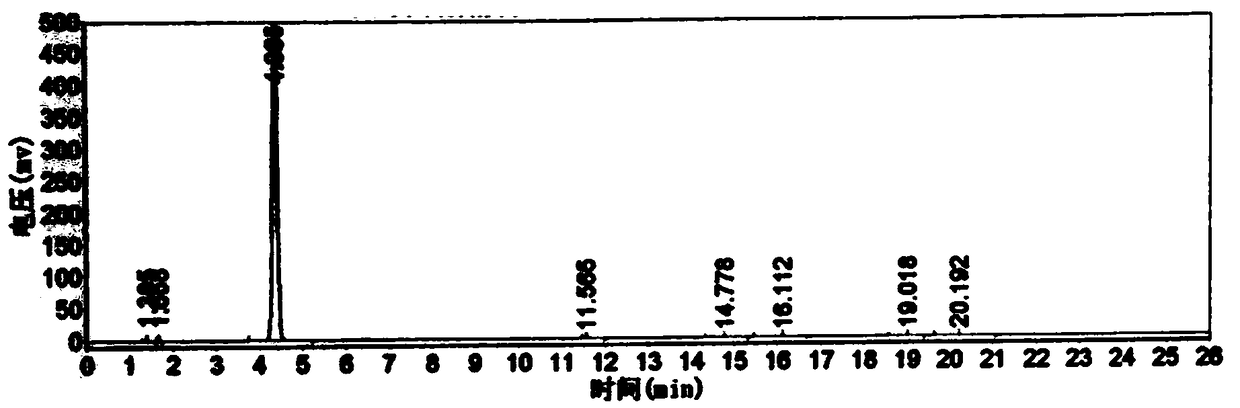

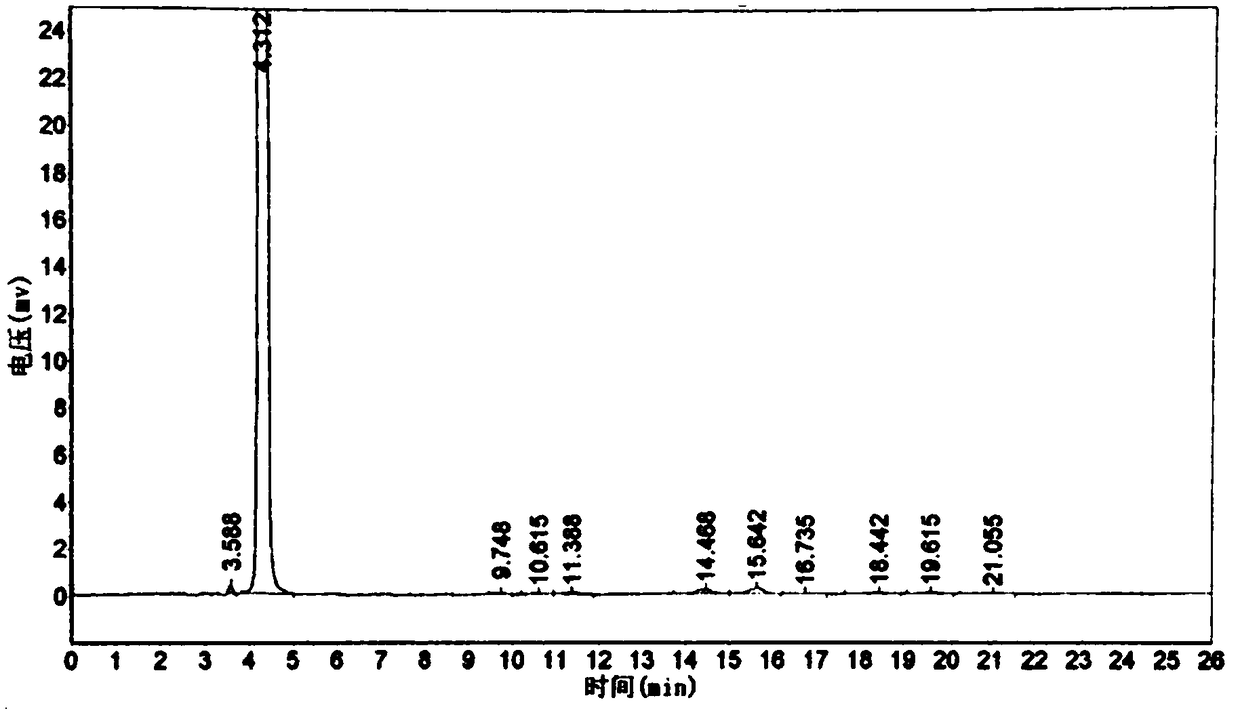

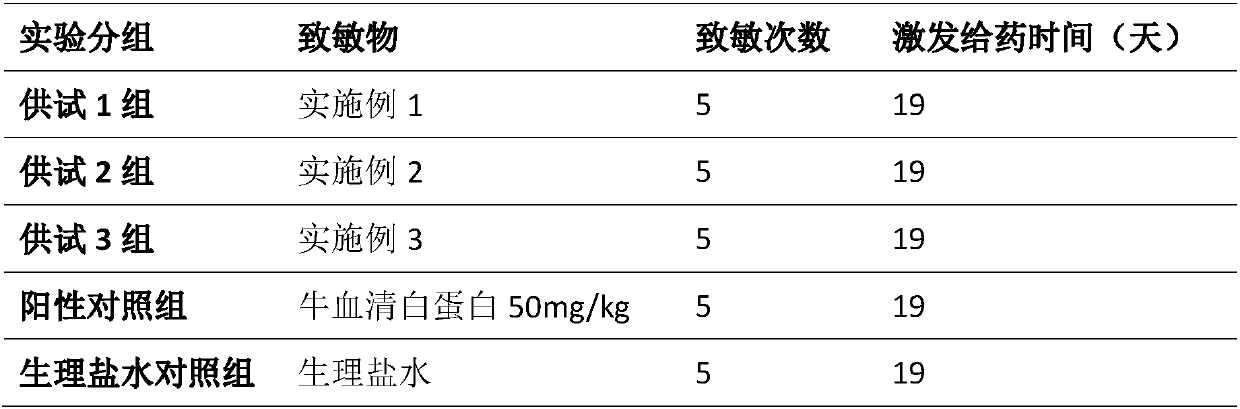

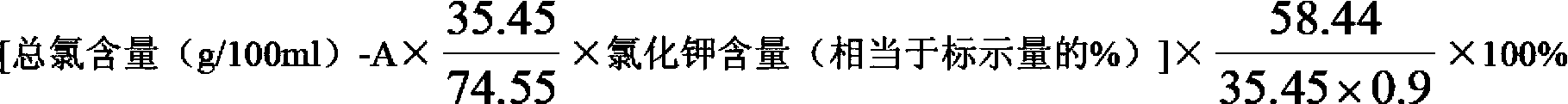

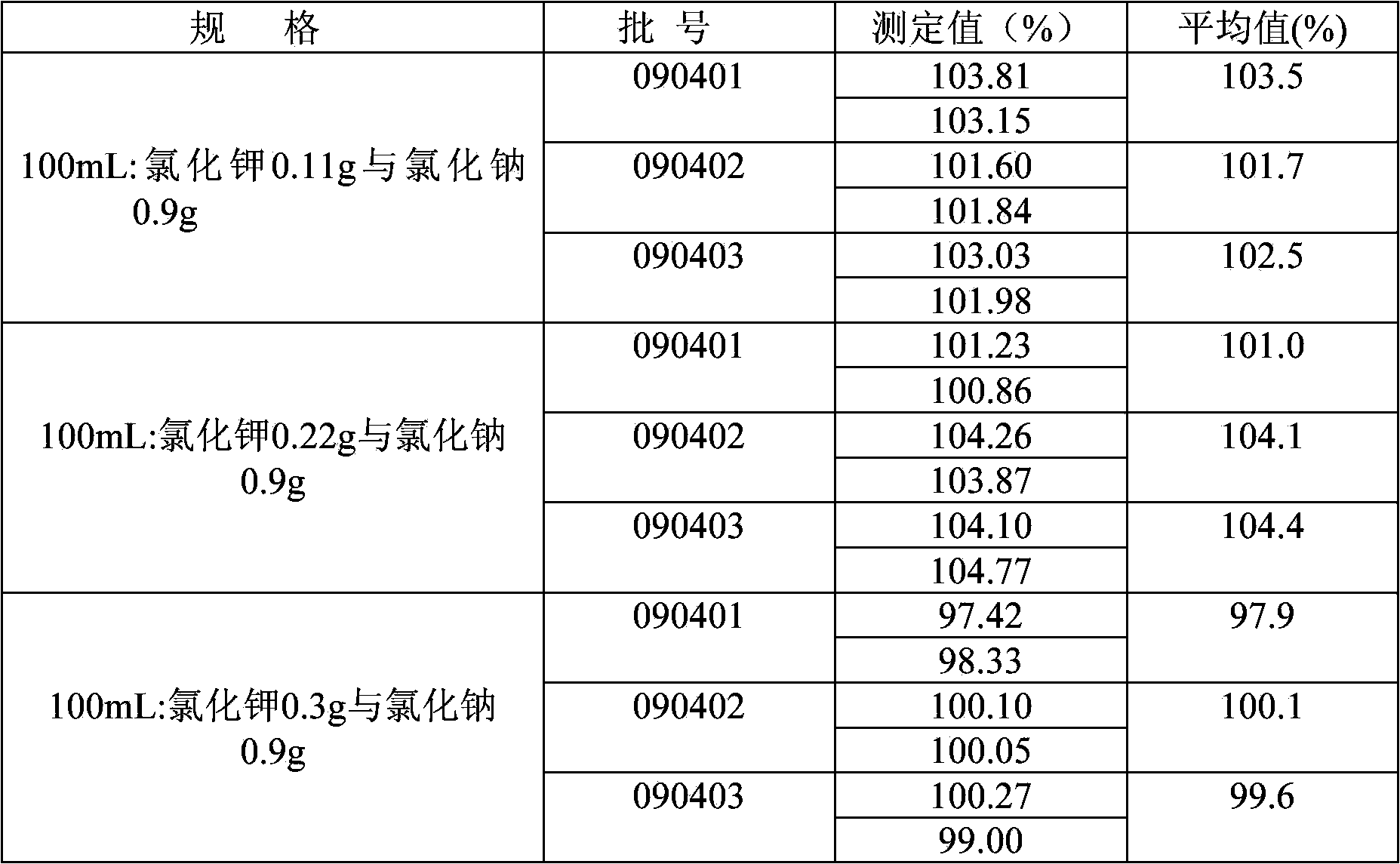

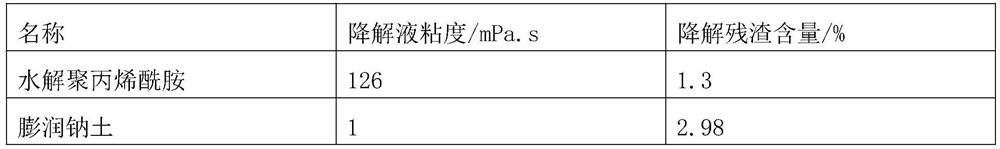

Quality control method of potassium chloride and sodium chloride injection

ActiveCN103575866AEnsure safetyStrict and reasonable controlMetabolism disorderSurface/boundary effectSodium Chloride InjectionQuality control

The invention relates to a quality control method of a potassium chloride and sodium chloride injection. The quality control method comprises the following steps: determining the content, detecting properties, identifying and detecting. The content determination step comprises the determination of the total chlorinity, the potassium chloride content and the sodium chloride content; the detecting step comprises the detection of pH values, heavy metals, arsenic salts, insoluble particles, osmotic pressure ratios, bacterial endotoxin and sterility. The quality control method provides detection indexes, detection means, technical methods and the like for related production and detection mechanisms so as to control the quality of products, ensure the safety of medicines, better guide production and enable the production process control to be strict and reasonable.

Owner:SICHUAN QILI PHARM CO LTD

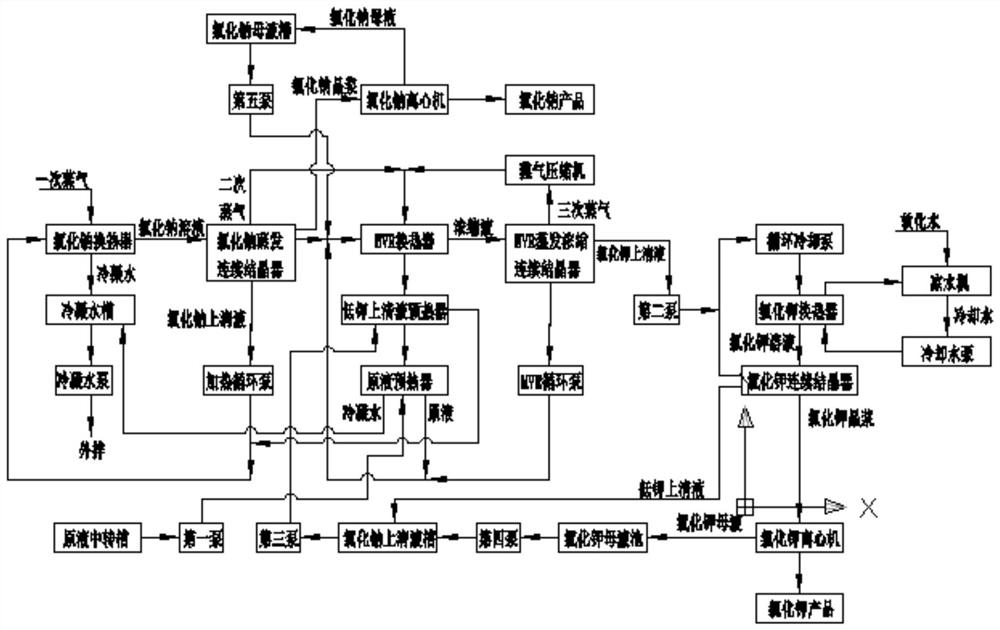

Composite MVR evaporative crystallization separation method for potassium and sodium chlorate mixture wastewater

PendingCN113697884AReduce energy consumptionGood energy saving effectWater contaminantsChemical industrySodium chloratePhysical chemistry

The invention relates to a composite MVR evaporative crystallization separation method for potassium and sodium chlorate mixture wastewater, which comprises the following steps: firstly, evaporating and concentrating a wastewater stock solution containing potassium chloride and sodium chloride mixed salt into a concentrated solution in an MVR evaporative concentration continuous crystallizer; feeding concentrated supernate at the upper part of a separation chamber at the lower part of the MVR evaporation and concentration continuous crystallizer into a potassium chloride continuous crystallizer for cold crystallization to separate out potassium chloride, and feeding low-potassium supernate at the upper part of the potassium chloride continuous crystallizer into a sodium chloride evaporation continuous crystallizer for further evaporation and concentration to separate out sodium chloride; feeding the low-sodium supernate at the upper part of the separation chamber at the lower part of the sodium chloride evaporation continuous crystallizer into the MVR evaporative concentration continuous crystallizer; and evaporating the wastewater stock solution and separating potassium and sodium salts. Compared with an existing multi-effect evaporation hot and cold crystallization separation method and an MVR evaporation crystallization separation method, the method can save energy by 30-45%, and has the advantages of being low in energy consumption, good in energy-saving effect, small in equipment investment and the like.

Owner:刘瀚文

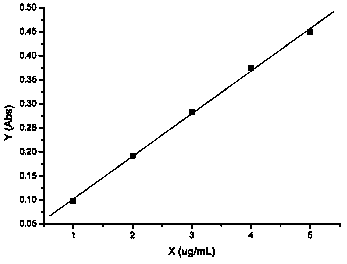

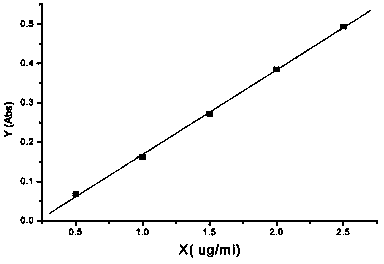

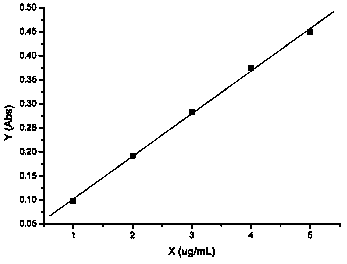

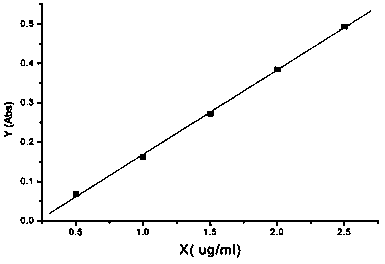

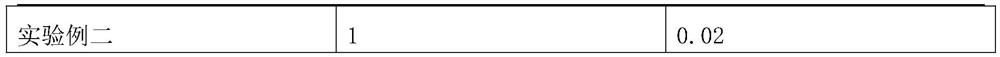

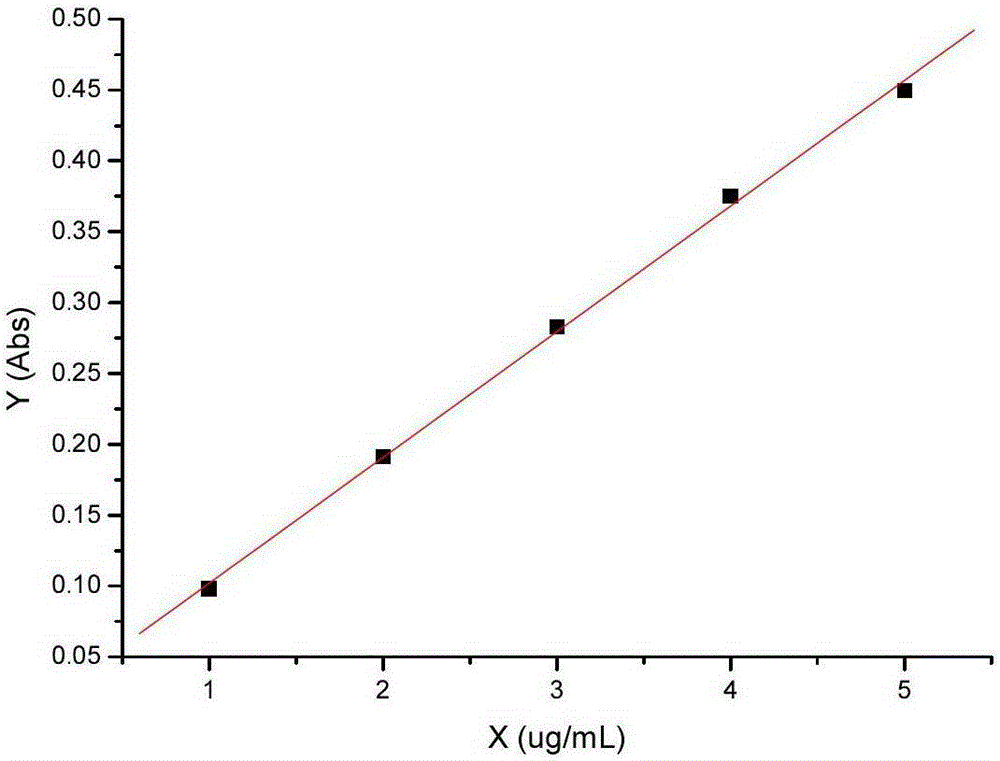

Method for measuring content of potassium chloride and sodium chloride in potassium chloride and sodium chloride injection solution

ActiveCN103575669AEasy to useReduce the chance of secondary pollutionColor/spectral properties measurementsSodium Chloride InjectionPOTASSIUM CHLORIDE/SODIUM CHLORIDE

The invention relates to a method for measuring the content of potassium chloride and sodium chloride in a potassium chloride and sodium chloride injection solution, and a method for determining whether the content of potassium chloride and sodium chloride in the potassium chloride and sodium chloride injection solution meets quality standards. The measuring method is carried out through an atomic absorption spectrometry method by an atomic absorption spectrophotometer.

Owner:SICHUAN QILI PHARM CO LTD

Cell, tissue and microorganism preservation solution, preparation method and application

InactiveCN108587911ALow priceLow transport environment requirementsDead animal preservationMicroorganism preservationMicroorganism preservationPotassium

The invention discloses a cell, tissue and microorganism preservation solution, a preparation method and application, and belongs to the field of medical systems. The cell, tissue and microorganism preservation solution comprises the raw materials of one or more of potassium chloride, sodium chloride, disodium hydrogen phosphate, trisodium phosphate, glycerine, phenol, dithiothreitol, ethylene diamine tetraacetic aci, cetyltrimethyl ammonium bromide, cetyltrimethyl ammonium chloride, hexadecyl trimethyl ammonium chloride, Hexadecyl trimethyl ammonium chloride, pigment and distilled water. Thecell, tissue and microorganism preservation solution is lower in price and has lower requirements on transportation environment.

Owner:江西业力医疗器械有限公司

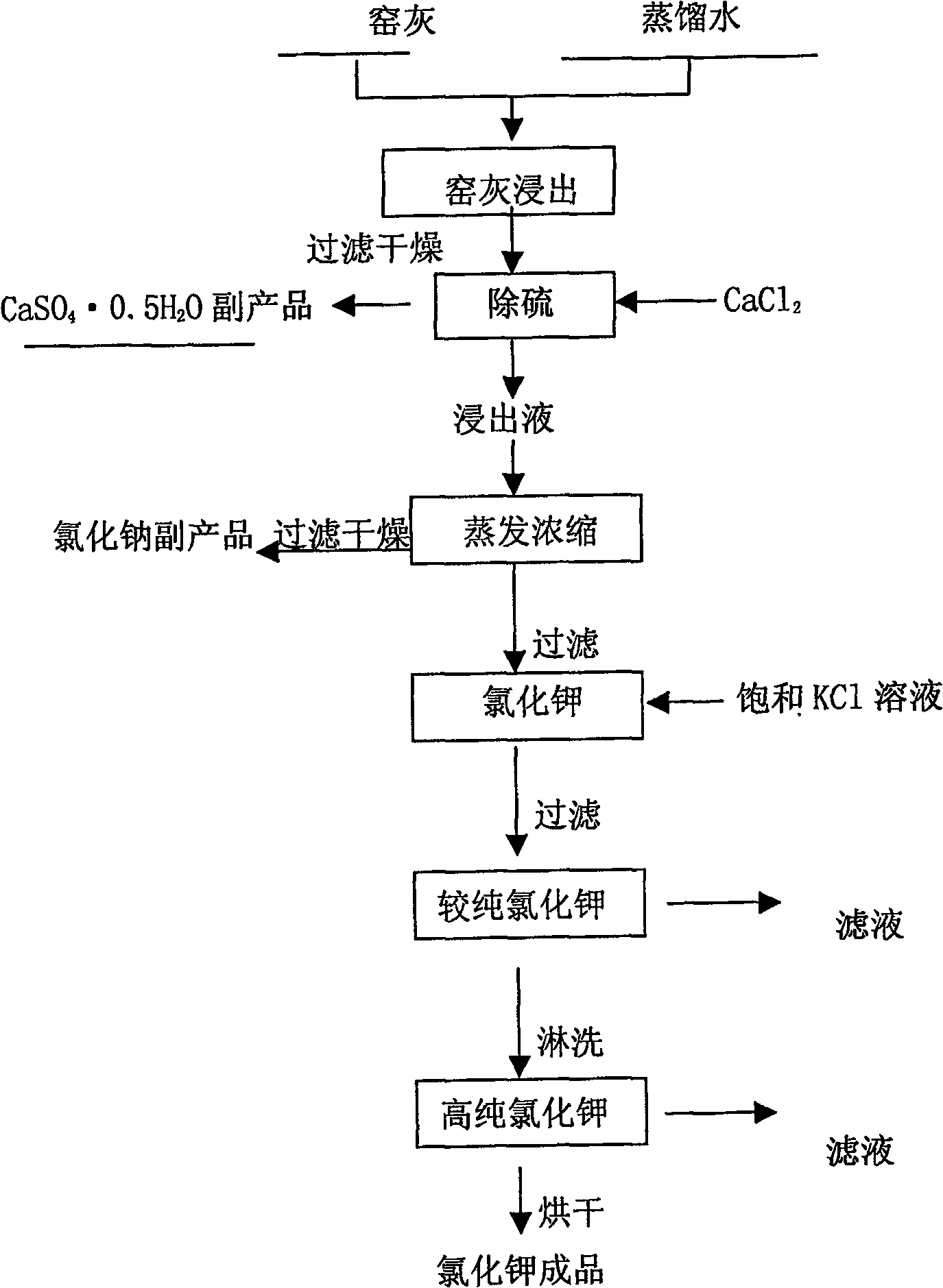

Process of producing potassium chloride with sintered ash from chamotte kiln

ActiveCN100560495CReduce manufacturing costReduce pollutionSolid waste disposalAlkali metal chloridesEvaporationImpurity

The invention relates to a method for producing potassium chloride by using alumina clinker kiln dust in a sintering method, which belongs to the production technology of potassium salt. Firstly, the kiln dust is leached with distilled water, and the leaching solution is added with a desulfurizing agent for desulfurization, and the desulfurized leaching solution is heated, Evaporate and concentrate, conduct the first crystallization, separate the crystals, evaporate and concentrate the separated primary crystallization mother liquor again, cool to obtain the second crystallization, separate the crystallization, evaporate and concentrate the filtrate and heat it to 80-99°C to become a saturated solution , plus seed crystals, and after cooling and natural cooling, mixed potassium chloride crystals are precipitated. Make full use of alumina kiln dust, turn waste into treasure, reduce environmental pollution caused by waste discharge, and reduce the production cost of potassium chloride. The product potassium chloride and by-products can be obtained through water leaching, impurity removal, evaporation and crystallization of kiln dust Sodium chloride and CaSO4·0.5H2O, and the process is short, low energy consumption, easy to operate, which is beneficial to obtain potassium chloride products with high purity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

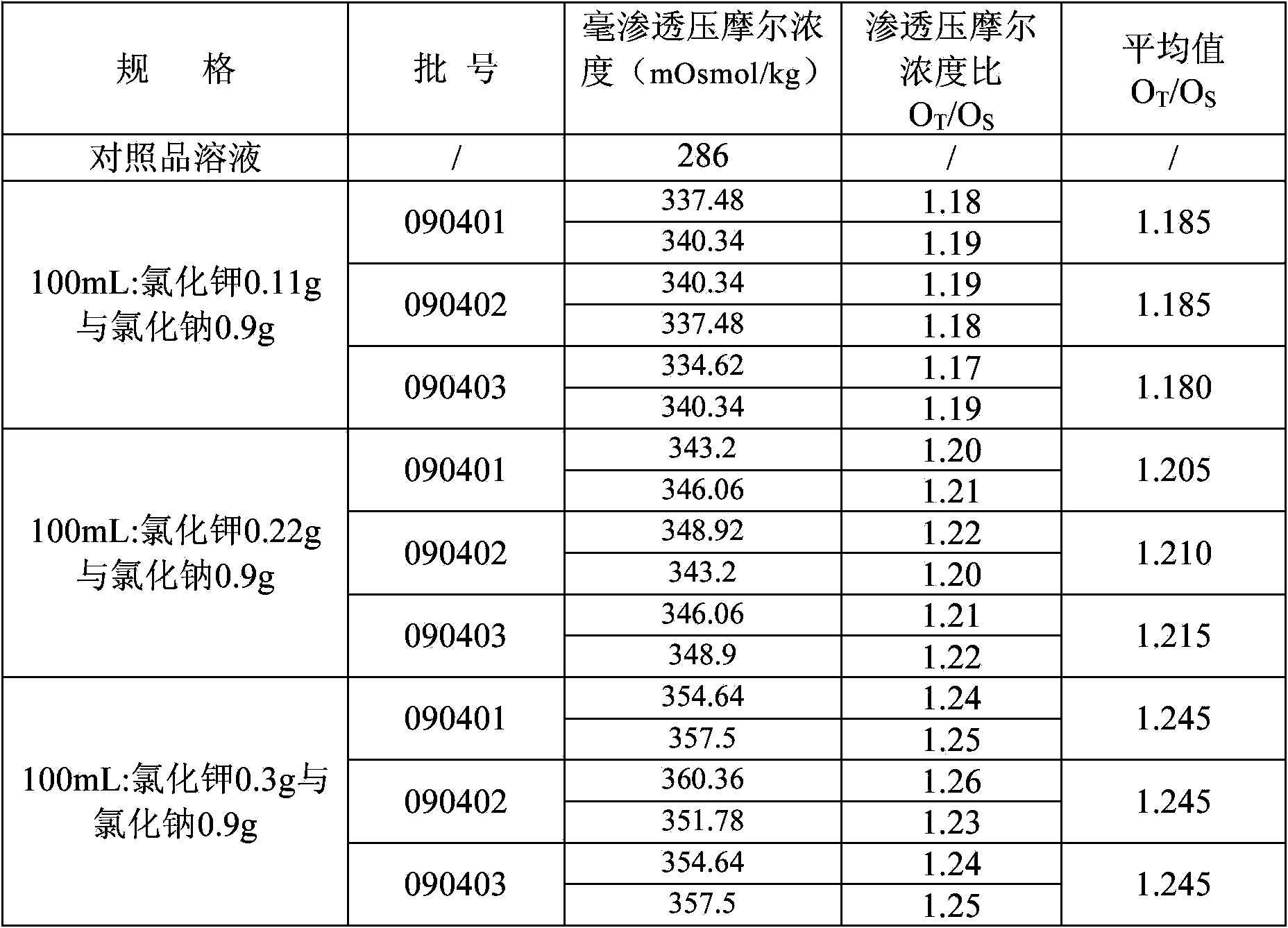

Potassium chloride and sodium chloride injection and determination method of osmotic pressure molar concentration ratio thereof

InactiveCN103575867AOsmolarity ControlGuaranteed qualityPreparing sample for investigationTesting medicinal preparationsSodium Chloride InjectionChloride

The invention provides a potassium chloride and sodium chloride injection and a determination method of the osmotic pressure molar concentration ratio thereof. The determination method comprises the following steps: (1) preparing a reference substance solution; (2) preparing a solution for test products; and (3) respectively determining the osmotic pressure molar concentration OS of the reference substance solution and the osmotic pressure molar concentration OT of the solution for test products by using an osmometer, thus obtaining the osmotic pressure molar concentration ratio of OT: OS.

Owner:SICHUAN QILI PHARM CO LTD

Process for the production of potassium sulphate and magnesium sulphate from carnallite and sodium sulphate

According to some embodiments there is provided a process for the recovery of SOP from Sulphate bearing mineral and Carnallite or Sylvenite, comprising: Dissolving Carnallite in water to obtain Sylvenite and high Magnesium Chloride brine; Adding Sodium Sulphate to said Carnallite to produce mixture of Kainte\Leonite, KCl and NaCl precipitant and brine containing Mg Cl2, KCl, NaCl; Separating the NaCl from the mixture; Obtaining a precipitant mixture of Leonite with KCl; Filtering said Leonite and washing with water to yield pure mixture of Leonite with KCl; Adding KCl to the Leonite with the KCl; and Decompose said Leonite with the KCl to SOP.

Owner:DEAD SEA WORKS

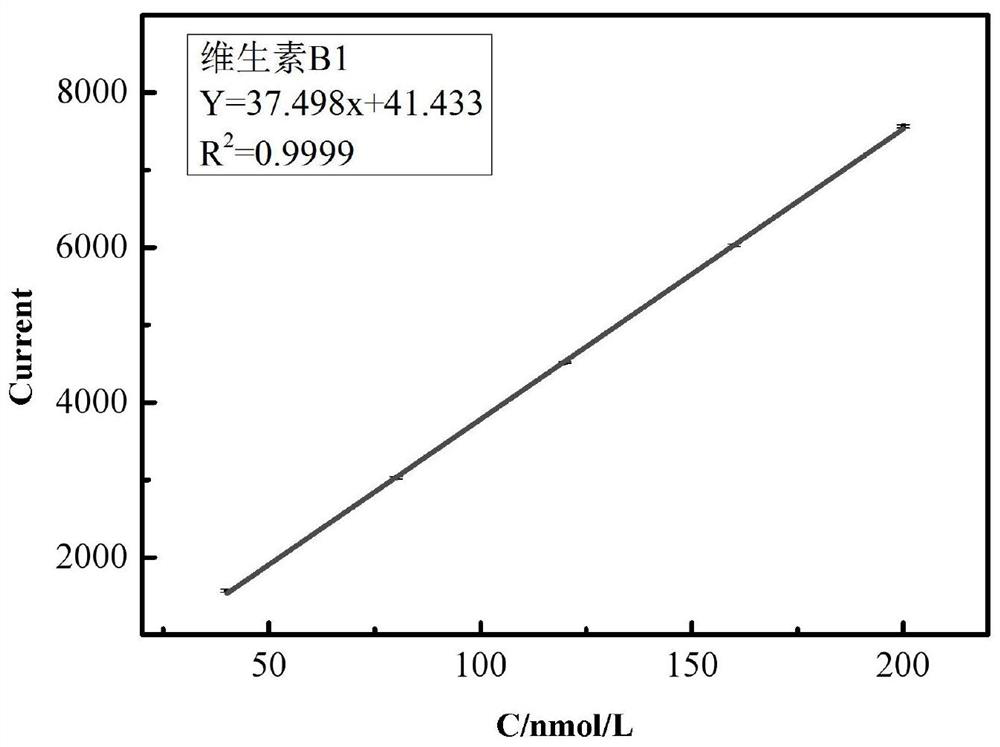

Preparation method of modified electrode for detecting vitamin B1 and detection method thereof

InactiveCN112557470AAccurate measurementHigh sensitivityMaterial electrochemical variablesInfrared lampCopper electrode

The invention belongs to the technical field of vitamin detection methods, and particularly relates to a preparation method of a modified electrode for detecting vitamin B1. The method comprises the following steps: selecting a glassy carbon electrode or a copper electrode as a matrix electrode, and polishing and cleaning the surface of the matrix electrode for later use; and dropwise coating or electroplating a modification solution on the surface of the matrix electrode, and drying by using an infrared lamp to obtain the modified electrode, wherein the modification solution is composed of one or more of hydrochloric acid, nitric acid, acetic acid, bismuth nitrate, mercury nitrate, silver nitrate, potassium chloride, sodium chloride, cadmium nitrate, lead nitrate and amino black 10B, andthe concentration of each component ranges from 0.0001 mol / L to 1 mol / L. The method overcomes the defects in the prior art, has the advantages of high sensitivity, good reproducibility, convenience and quickness in operation and the like, and accurately measures the content of vitamin B1 in a blood sample.

Owner:合肥天一生物技术研究所有限责任公司

Preparation method of aluminum phosphate adjuvant

PendingCN114796478AReduce processing difficultyReduce manufacturing costAntibody medical ingredientsPhosphorus compoundsSodium bicarbonateAdjuvant

The invention provides a preparation method of an aluminum phosphate adjuvant, which comprises the following steps: respectively dissolving potassium chloride, sodium chloride, sodium dihydrogen phosphate and sodium bicarbonate in distilled water, mixing and dissolving, diluting with distilled water, dissolving calcium chloride in a test tube, dropwise adding the calcium chloride solution in the test tube into the solution to obtain a mixed solvent, and standing for layering; the ozone reaction utilizes a large amount of hydroxyl free radicals and nascent oxygen generated in the ozone reaction to indirectly oxidize inorganic matters and organic matters in water, and enters into cells of bacteria to oxidize intracellular organic matters, so that sterilization and disinfection are achieved, and ozone can be quickly and automatically decomposed into oxygen or single oxygen atoms due to poor stability, so that the water quality is improved. The single oxygen atoms can be automatically combined into oxygen molecules, no toxic residues exist, the technological difficulty of manufacturing the aluminum phosphate adjuvant is reduced through the sterilization method, and the preparation cost of the aluminum phosphate adjuvant is reduced.

Owner:HUAYU WU XI PHARMA

Plugging agent for temporary plugging in oil and gas well repairing

PendingCN113621356AImprove pressure bearing capacityAchieve hydrolysisDrilling compositionMeth-Benzoyl peroxide

The invention belongs to a plugging agent for temporary plugging in oil and gas well repairing. The plugging agent comprising the following raw materials in parts by mass: 20 to 40 parts of a polymeric monomer, 5 to 10 parts of a biopolymer, 0.1 to 1.0 part of a cross-linking agent, 50 to 70 parts of a reinforcing agent, 0.01 to 0.05 part of a gel breaker and 0.001 to 0.003 part of an initiator, wherein the polymeric monomer is selected from a mixture of acrylamide and methacrylamide; the biopolymer is one selected from xanthan gum and guar gum; the cross-linking agent is selected from ethylene glycol dimethacrylate; the reinforcing agent is one or a mixture of more than one selected from potassium chloride, sodium chloride, sodium nitrate and potassium nitrate; the gel breaker is a mixture of benzoyl peroxide and ferrous sulfate, and a molar ratio of benzoyl peroxide to ferrous sulfate is (1-2): 1; and the initiator is 1-((cyano-1-methylethyl)azo)formamide. The plugging agent has the advantages that pressure-bearing strength is good, self-degradation release can be realized, and damage to a stratum is small.

Owner:北京国海能源技术研究院

A kind of preparation method of terbium-doped lithium manganese oxide material for lithium ion battery

ActiveCN106299337BImprove discharge capacityIncrease gram capacityCell electrodesSecondary cellsFiberManganate

The invention discloses a preparation method of a terbium-doped lithium manganate material for a lithium ion battery. The method comprises the following steps: (a) weighing lithium carbonate, manganese oxide and terbium oxide according to a stoichiometric ratio; (b) adding anhydrous ethanol into the raw materials weighed in the step a, carrying out ball milling, then taking out the product and drying to obtain a terbium-doped lithium manganate raw material; (c) adding acetate fiber and mixed molten salt of potassium chloride and sodium chloride into the terbium-doped lithium manganate raw material obtained in the step b, adding the anhydrous ethanol into the obtained mixture, carrying out ball milling and then drying; (d) sintering the raw material treated in the step c, cooling after sintering, washing the obtained powder with water, and drying to obtain the terbium-doped lithium manganate material. The terbium-doped lithium manganate material for the lithium ion battery has higher discharge capacity; the terbium-doped lithium manganate material has a hollow tubular structure and is loose in tube wall, thus relieving the problem of volume expansion caused in charging and discharging processes; the stability of the terbium-doped lithium manganate material is improved by using inorganic filler titanium dioxide in the acetate fiber.

Owner:ZHEJIANG CHANGXING KISUN POWER SUPPLY

Quality Control Method for Potassium Chloride and Sodium Chloride Injection

ActiveCN103575866BEnsure safetyStrict and reasonable controlMetabolism disorderSurface/boundary effectSodium Chloride InjectionQuality control

The invention relates to a quality control method of a potassium chloride and sodium chloride injection. The quality control method comprises the following steps: determining the content, detecting properties, identifying and detecting. The content determination step comprises the determination of the total chlorinity, the potassium chloride content and the sodium chloride content; the detecting step comprises the detection of pH values, heavy metals, arsenic salts, insoluble particles, osmotic pressure ratios, bacterial endotoxin and sterility. The quality control method provides detection indexes, detection means, technical methods and the like for related production and detection mechanisms so as to control the quality of products, ensure the safety of medicines, better guide production and enable the production process control to be strict and reasonable.

Owner:SICHUAN QILI PHARM CO LTD

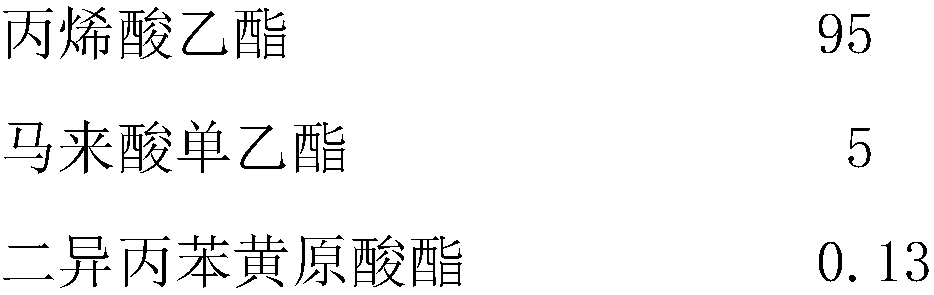

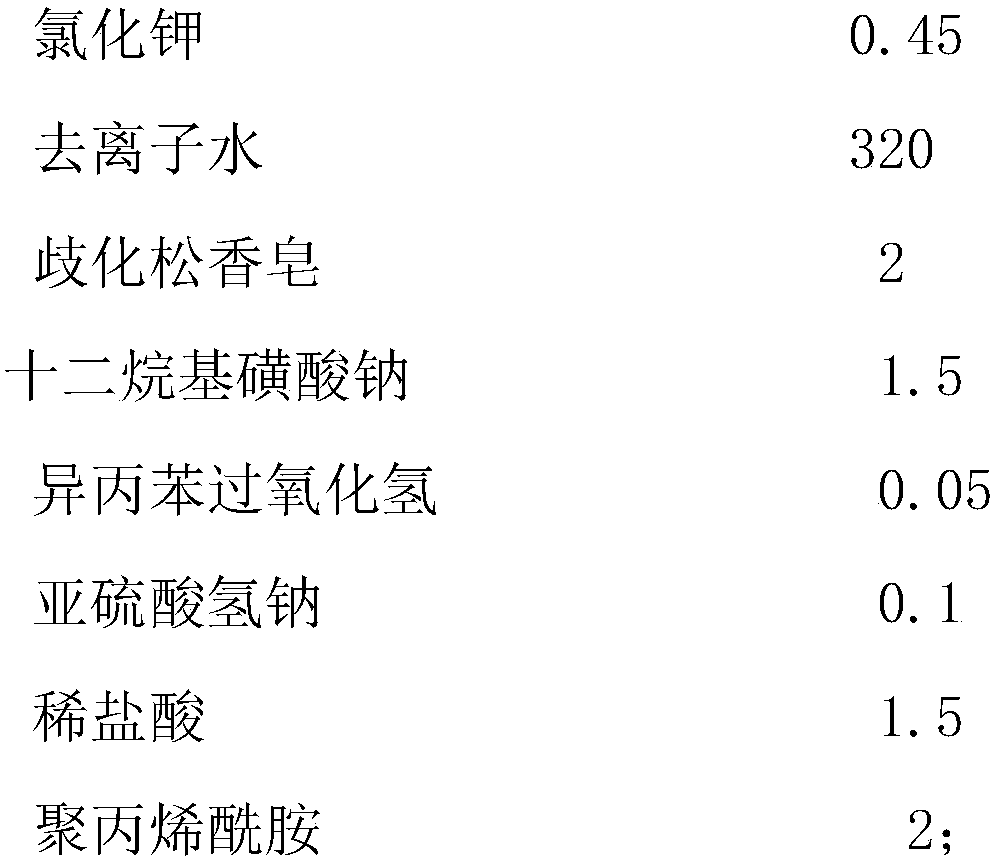

Process for preparing high Mooney viscosity polyacrylate compositions

ActiveCN106554461BHigh viscosityImprove polymerization conversion ratePolymer scienceMooney viscosity

The invention discloses a method for preparing a high Mooney viscosity polyacrylate composition, which comprises the steps of: 1) adding acrylate monomer raw materials, crosslinkable monomer raw materials and regulators into an emulsifier aqueous solution; 2) adding One of potassium chloride, sodium chloride, potassium sulfate, sodium sulfate, potassium nitrate or sodium nitrate is added to the emulsifier aqueous solution, and the dosage is 1 / 10000 to 5 / 1000; 3) Under the protection of nitrogen, the copolymerization reaction is initiated by free radicals; 4) After the copolymerization reaction is completed, a reducing agent is added for post-treatment; 5) A coagulant is added to break the emulsion, rinsed with water, and dehydrated to obtain a combined product. According to the method for preparing the high Mooney viscosity polyacrylate composition of the present invention, the Mooney viscosity of the prepared acrylate rubber generally increases, and the highest can reach more than 80.

Owner:鑫泓裕重庆复合材料有限公司

Method for preparing europium-doped lithium cobalt oxides for lithium ion battery

ActiveCN106299274AImprove discharge capacityIncrease gram capacityCell electrodesSecondary cellsFiberCobalt

A method for preparing europium-doped lithium cobalt oxides for a lithium ion battery includes the following steps that firstly, lithium carbonate, cobaltous oxide and europium oxide are weighed according to the stoichiometric ratio; secondly, anhydrous ethanol is added into the raw materials weighed in the first step, ball milling is conducted, the mixture is taken out and dried, and an europium-doped lithium cobalt oxide raw material is obtained; thirdly, acetate fiber and potassium chloride-sodium chloride mixed molten salt are added into the europium-doped lithium cobalt oxide raw material prepared in the second step, then anhydrous ethanol is added, ball milling is conducted, and then drying is conducted; fourthly, the raw materials processed in the third step are sintered and then cooled, obtained powder is washed with water and dried, and europium-doped lithium cobalt oxides are prepared. The europium-doped lithium cobalt oxides for the lithium ion battery have higher discharge capacity and gram volume and are of a hollow tubular structure, the pipe wall is of a loose structure, the volume expansion problem in the charging and discharging process can be relieved, and circulation performance of the lithium ion battery can be improved.

Owner:CHAOWEI POWER CO LTD

Method for extracting lithium carbonate from mixed salt of carbonate and chlorate

ActiveCN114762842AReduce energy consumptionLow costFlotationLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

A method for extracting lithium carbonate from mixed salt of carbonate and chlorate comprises the following steps: (1) carrying out ore grinding on the mixed salt of potassium chloride, sodium chloride, lithium carbonate and sodium carbonate obtained by tedding in a salt pan or evaporating by other equipment to obtain an ore pulp material; (2) the ore pulp material is fed into a flotation machine, a lithium carbonate collecting agent is added, flotation is conducted, and flotation froth lithium carbonate roughing concentrate is obtained; (3) the lithium carbonate roughing concentrate is subjected to concentration, an inhibitor is added before concentration and foam scraping, and lithium carbonate concentrate is obtained after concentration is completed; and (4) washing, filtering and drying the lithium carbonate concentrate to obtain a crude lithium carbonate product. The method is low in energy consumption, simple in process, high in lithium resource utilization rate and low in cost, the content of lithium carbonate in the obtained lithium carbonate product reaches 98% or above, and high-purity lithium carbonate can be effectively extracted from the extremely-low-lithium-grade lithium carbonate mixed salt.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

A kind of preparation method of 5-chloro-1-indanone

ActiveCN112457179BReduce dosageReduce pollutionOrganic compound preparationCarbonyl compound preparation by condensationAluminium chlorideChlorobenzene

The invention provides a preparation method of 5-chloro-1-indanone, which belongs to the technical field of organic synthesis. Taking chlorobenzene and 3-chloropropionyl chloride as raw materials, using mixed molten salt and heteropolyacid as a catalyst, and heating up to react to obtain 5-chloro-1-indanone; the heteropolyacid is SiO 2 Loading phosphotungstic acid, the mixed molten salt is a mixture of any two or three of potassium chloride, sodium chloride and aluminum chloride. In the present invention, by controlling the feeding temperature and feeding sequence, the reaction is carried out at a relatively low temperature, avoiding the problems of using aluminum trichloride as a catalyst with a large amount of solids, high temperature, violent reaction, large amount of tar, carbonization of raw materials, and more three wastes. , the yield of 5-chloro-1-indanone can be as high as 85%.

Owner:FUXIN RUIGUANG FLUORINE CHEM

A kind of preparation method of europium-doped lithium cobalt oxide for lithium ion battery

ActiveCN106299274BImprove discharge capacityIncrease gram capacityCell electrodesSecondary cellsFiberErbium doping

A method for preparing europium-doped lithium cobalt oxides for a lithium ion battery includes the following steps that firstly, lithium carbonate, cobaltous oxide and europium oxide are weighed according to the stoichiometric ratio; secondly, anhydrous ethanol is added into the raw materials weighed in the first step, ball milling is conducted, the mixture is taken out and dried, and an europium-doped lithium cobalt oxide raw material is obtained; thirdly, acetate fiber and potassium chloride-sodium chloride mixed molten salt are added into the europium-doped lithium cobalt oxide raw material prepared in the second step, then anhydrous ethanol is added, ball milling is conducted, and then drying is conducted; fourthly, the raw materials processed in the third step are sintered and then cooled, obtained powder is washed with water and dried, and europium-doped lithium cobalt oxides are prepared. The europium-doped lithium cobalt oxides for the lithium ion battery have higher discharge capacity and gram volume and are of a hollow tubular structure, the pipe wall is of a loose structure, the volume expansion problem in the charging and discharging process can be relieved, and circulation performance of the lithium ion battery can be improved.

Owner:CHAOWEI POWER CO LTD

Super-cooling nickel base high-temperature alloy purifying agent and preparation method thereof

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com