Composite MVR evaporative crystallization separation method for potassium and sodium chlorate mixture wastewater

A technology of evaporative crystallization and separation method, which is applied in the direction of evaporative separation crystallization, chemical instruments and methods, solution crystallization, etc., which can solve the problems of high energy consumption and low energy saving effect, and achieve improved heat exchange efficiency, reduced equipment investment, and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

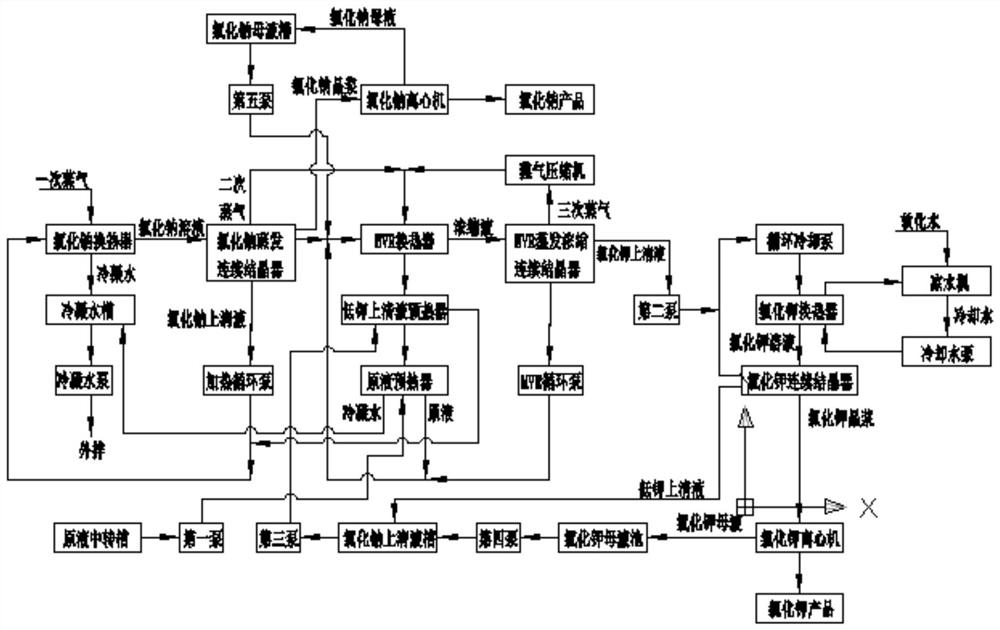

[0025] Such as figure 1 Shown: a kind of potassium, sodium chloride salt mixture waste water compound type MVR evaporation crystallization separation method, its method is:

[0026]First, the waste water stock solution containing potassium chloride and sodium chloride mixed salt in the stock solution transfer tank is pumped into the stock solution preheater with the first pump and enters the MVR heat exchanger MVR evaporation concentration continuous crystallizer, and then passes through the second pump and circulation The cooling pump is pumped into the potassium chloride continuous crystallizer through the potassium chloride heat exchanger, and then enters the chlorine through the low-potassium supernatant tank, the third pump, the low-potassium supernatant preheater, and the sodium chloride heat exchanger. Sodium chloride evaporates in the continuous crystallizer, then opens the steam inlet valve once, and then starts the heating circulation pump, so that the stock solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com