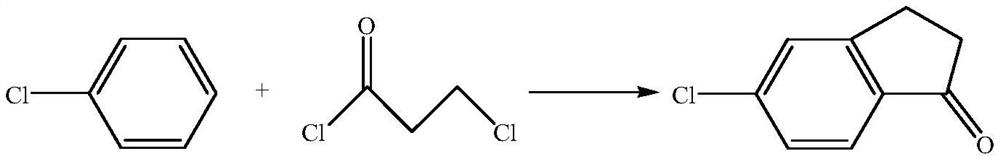

Preparation method of 5-chloro-1-indanone

A technology of indanone and chlorobenzene, which is applied in the field of preparation of 5-chloro-1-indanone, can solve the problems of easy blockage of exhaust pipes, large amount of aluminum trichloride, and high reaction temperature, and achieves simple process and equipment requirements Low, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In a 2000mL jacketed reactor, add 338g (3mol) of chlorobenzene and cool down to below 5°C, then add 420g (3.15mol) of aluminum trichloride and stir for 0.5h. Start to add 381 g (3 mol) of 3-chloropropionyl chloride dropwise, and complete the addition within 2 hours. After the addition, the temperature was raised to 50° C., and after 2 hours of heat preservation and reaction, the GC controlled the reaction raw materials to be ≤0.5%. Add 300g of aluminum trichloride, 90g of sodium chloride and 30g of potassium chloride to another jacketed kettle, and heat the jacketed heat transfer oil to a molten state. The reaction solution after the heat preservation was completed was added dropwise to the molten salt for 1 hour. After the dropwise addition, the temperature was raised to 130° C. for 6 hours, and the reaction was completed. Add the reaction feed liquid to 4000g of ice water for hydrolysis, control the temperature of the hydrolysis kettle to ≤50°C, stir and cool down to...

Embodiment 2

[0040]In a 2000mL jacketed reactor, add 338g (3mol) of chlorobenzene and cool down to below 5°C, then add 420g (3.15mol) of aluminum trichloride and stir for 0.5h. Start to add 381 g (3 mol) of 3-chloropropionyl chloride dropwise, and complete the addition within 2 hours. After the addition, raise the reaction temperature to 70° C., and keep the reaction for 2 hours, and control the reaction raw materials in GC to ≤0.5%. Add 600g of aluminum trichloride and 260g of sodium chloride to another jacketed kettle, heat the jacketed heat conduction oil to a molten state, add the reaction solution that has been kept warm for 1 hour, and raise the temperature to 150°C for 3 hours after the dropwise addition, and the reaction is completed. Add the reaction feed liquid to 5000g of ice water for hydrolysis, control the temperature of the hydrolysis kettle to ≤50°C, stir and cool down to below 20°C after dropping, filter, add the filter cake to the reaction kettle, add 1000g of methanol, h...

Embodiment 3

[0042] 1000mL jacketed reactor, add SiO 2 Loaded phosphotungstic acid catalyst (loading capacity 30%) 31.8g, aluminum trichloride 210g, sodium chloride 90g and potassium chloride 49g, heated to 90°C in a jacketed oil bath, kept warm for 0.5h, and controlled the temperature of the reactor at 100-110 ℃, add 190.5g (1.5mol) of 3-chloropropionyl chloride dropwise for 1.5h, after dropping, keep warm at this temperature for 30 minutes, start to add 169g (1.5mol) of chlorobenzene dropwise, take 1h, and keep warm for 4h after adding Afterwards, the GC middle control intermediate ≤ 0.5%, the reaction ends. Add the reaction feed liquid to 1250g of ice water for hydrolysis, control the temperature of the hydrolysis kettle to ≤50°C, stir and cool down to below 20°C after dropping, filter, add the filter cake into the reaction kettle, add 500g of methanol, heat to reflux, keep warm for 3h, heat Filter, wash the filter cake with chloroform heat, filter, rinse and dry, and recover the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com