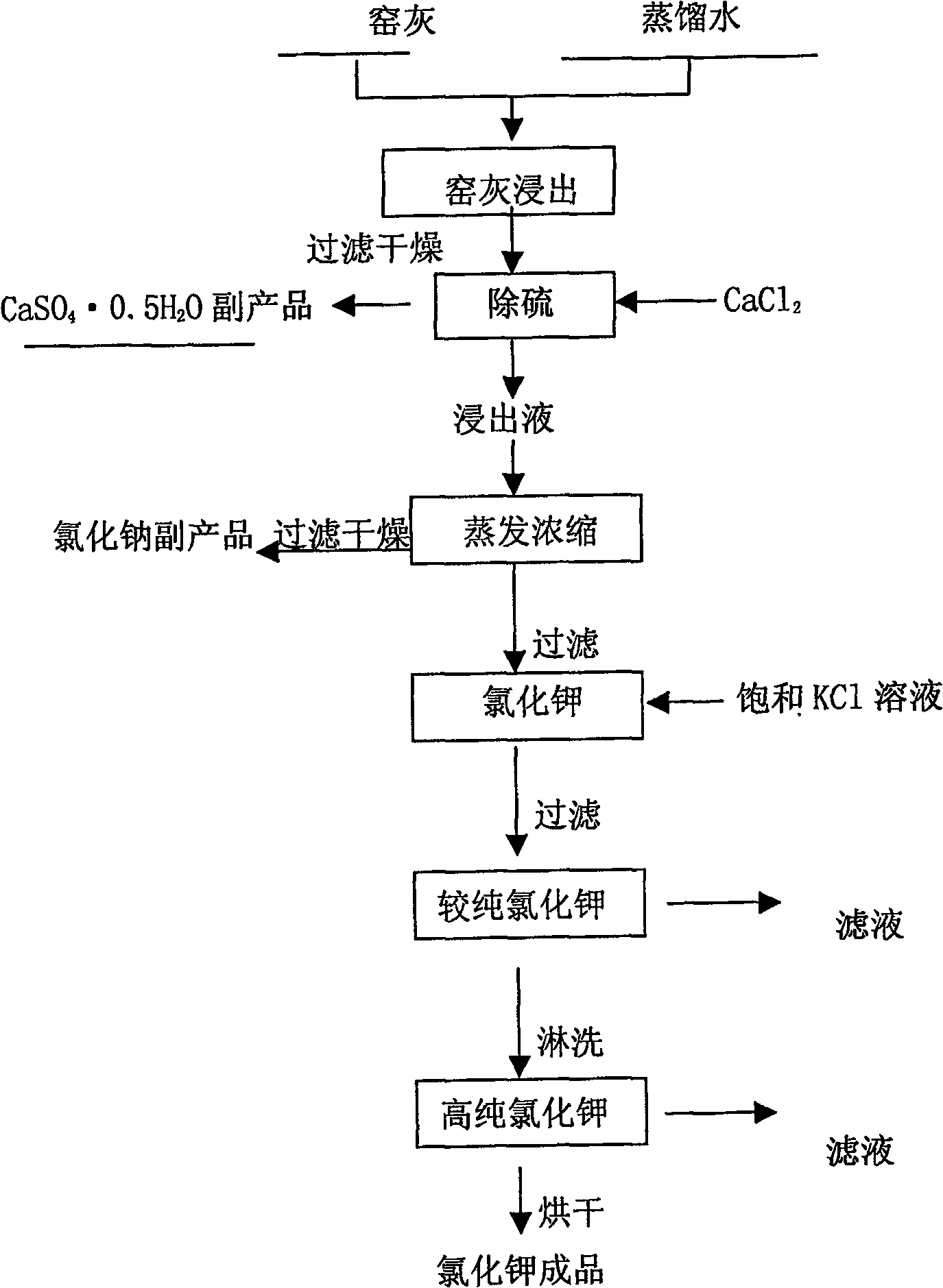

Process of producing potassium chloride with sintered ash from chamotte kiln

A potassium chloride and clinker kiln technology, applied in the removal of alkali metal chloride and solid waste, can solve the problems of high operating cost, waste, and high cost, and achieve the goal of reducing environmental pollution, reducing production costs, and being easy to control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method of utilizing alumina kiln dust to produce potassium chloride of the present invention, operation is as follows:

[0032] First, use distilled water at a liquid-solid ratio of 0.9 to stir and leach the kiln dust at a constant speed of 90°C, keep the leachate at 60°C for 30 minutes, and add the chemical reagent CaCl 2 Stir to remove impurity SO 4 2- , the total desulfurization rate can reach 90%, and the final product of the desulfurization reaction is CaSO 4 0.5H 2 O, its particle size D 50 : 6.526μm, can be sold as a by-product.

[0033] Heating, evaporating, and concentrating the desulfurized solution until the volume of the slurry is 3 / 5 of the volume before evaporation and concentration. At this time, crystals are precipitated from the solution. The precipitated crystals are NaCl with a purity of more than 90% and can be sold as by-products . Keep the mother liquor at 95°C, add industrial potassium chloride with a fineness of 75-150 μm to the mother ...

Embodiment 2

[0035] The method of utilizing alumina kiln dust to produce potassium chloride of the present invention, operation is as follows:

[0036] Use distilled water at a liquid-solid ratio of 1.0 to stir and leach the kiln dust at a constant speed at 90°C, keep the leachate at 90°C for 30 minutes, carry out liquid-solid separation at this temperature, and add chemical reagent CaCl to the mother liquor 2 Stir to remove impurity SO 4 2- , the total desulfurization rate can reach 92%, and the final product of the desulfurization reaction is CaSO 4 0.5H 2 O, its particle size D 50 : 6.326μm, can be sold as a by-product.

[0037] The desulfurized solution is heated, evaporated, and concentrated until the volume of the slurry is 3 / 5 of the volume before evaporation and concentration. At this time, crystals are precipitated from the solution. The precipitated crystals are NaCl with a purity of 91%, which can be sold as by-products. Keep the mother liquor at 95°C, add industrial potass...

Embodiment 3

[0039] The method of utilizing alumina kiln dust to produce potassium chloride of the present invention, operation is as follows:

[0040] Use distilled water at a liquid-solid ratio of 1.1 to stir and leach kiln dust at a constant speed at 90°C, keep the leaching liquid at 90°C for 30 minutes, carry out liquid-solid separation at this temperature, and add chemical reagent CaCl to the mother liquor 2 Stir to remove impurity SO 4 2- , the total desulfurization rate can reach ≥90%, and the final product of the desulfurization reaction is CaSO 4 0.5H 2 O, its particle size D 50 : 7.523μm, can be sold as a by-product.

[0041]The desulfurized solution is heated, evaporated, and concentrated until the volume of the slurry is 1 / 5 of the volume before evaporation and concentration. At this time, crystals are precipitated from the solution. The precipitated crystals are NaCl with a purity of 90%. They can be sold as by-products. Keep the mother liquor at 95°C, add industrial pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com