Quality control method of potassium chloride and sodium chloride injection

A technology of potassium chloride, sodium chloride, and quality control methods, which is applied to the active ingredients of alkali/alkaline earth metal chlorides, pharmaceutical formulas, and measuring devices, and can solve the problems of inconspicuous titration end-point jumps, time-consuming, and complicated operating procedures, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] 1) Preparation of blank test solution:

[0022] Dissolve 0.9g of sodium chloride with water and dilute to 100mL, shake well, accurately measure 5.0mL of the resulting solution, put it in a 50mL measuring bottle, add water to dilute to the mark, shake well, and obtain a blank test solution;

[0023] 2) Preparation of reference substance solution:

[0024] Accurately measure 5.0mL of potassium standard solution with a concentration of 1000μg / mL, place it in a 50mL measuring bottle, dilute with water to the mark, and shake well to obtain a solution with a concentration of 100μg / mL. Accurately measure 1.0mL of a 100μg / mL solution 2.0mL, 3.0mL, 4.0mL and 5.0mL were placed in 100mL measuring bottles respectively, and then 5.0mL of the blank test solution was precisely added, diluted to the mark with water, and shaken well to obtain the reference substance solution;

[0025] 3) Preparation of the test solution:

[0026] Precisely measure the sample to be tested, dilute with ...

Embodiment 1

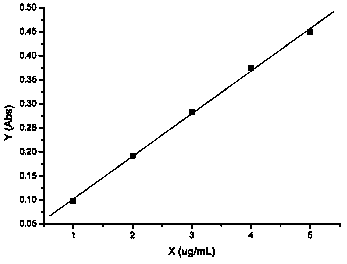

[0065] The mensuration of embodiment 1 potassium chloride content

[0066] 1) Preparation of blank test solution:

[0067] Dissolve 0.9g of sodium chloride with water and dilute to 100mL, shake well, accurately measure 5.0mL of the resulting solution, put it in a 50mL measuring bottle, add water to dilute to the mark, shake well, and obtain a blank test solution;

[0068] 2) Preparation of reference substance solution:

[0069] Precisely measure 5.0 mL of potassium standard solution ([National Standard Solution GBS G 62020-90 (2601)] National Iron and Steel Materials Testing Center, General Iron and Steel Research Institute) with a concentration of 1000 μg / mL and a medium of 10% HCl, and place it in a 50 mL volume In the bottle, dilute to the mark with water, shake well to obtain a solution with a concentration of 100μg / mL, accurately measure 1.0mL, 2.0mL, 3.0mL, 4.0mL and 5.0mL of the 100μg / mL solution, and place them in 100mL measuring bottles , and then precisely add 5.0m...

Embodiment 2

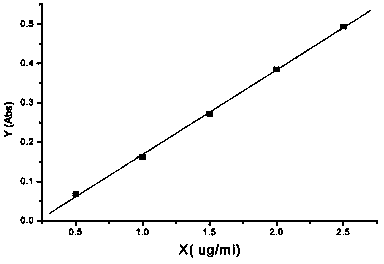

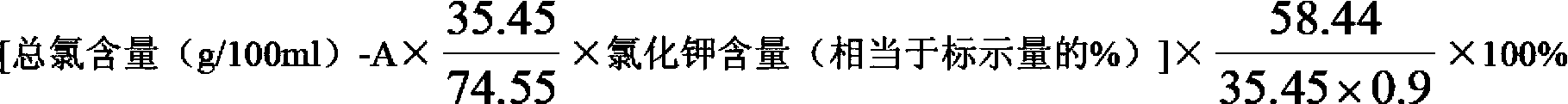

[0111] The mensuration of embodiment 2 sodium chloride content

[0112] 1) Preparation of blank test solution:

[0113] Dissolve 0.3g of potassium chloride with water and dilute to 100mL, shake well, accurately measure 5.0mL of the resulting solution, place it in a 100mL measuring bottle, add water to dilute to the mark, shake well, and obtain a blank test solution;

[0114] 2) Preparation of reference substance solution:

[0115] Precisely measure 5.0 mL of sodium standard solution ([National Standard Solution GBSG 62020-90 (2601)] National Iron and Steel Materials Testing Center, General Iron and Steel Research Institute) with a concentration of 1000 μg / mL and a medium of 10% HCl, and place it in a 100 mL measuring bottle , dilute to the mark with water, and shake well to obtain a solution with a concentration of 50 μg / mL. Accurately measure 1.0 mL, 2.0 mL, 3.0 mL, 4.0 mL and 5.0 mL of the 50 μg / mL solution, and place them in 100 mL measuring bottles respectively. Then pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com