Groove suction vane for pump

A technology of grooves and vanes, which is applied in the field of grooved drainage vanes, can solve problems affecting pump performance and unfavorable flow separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

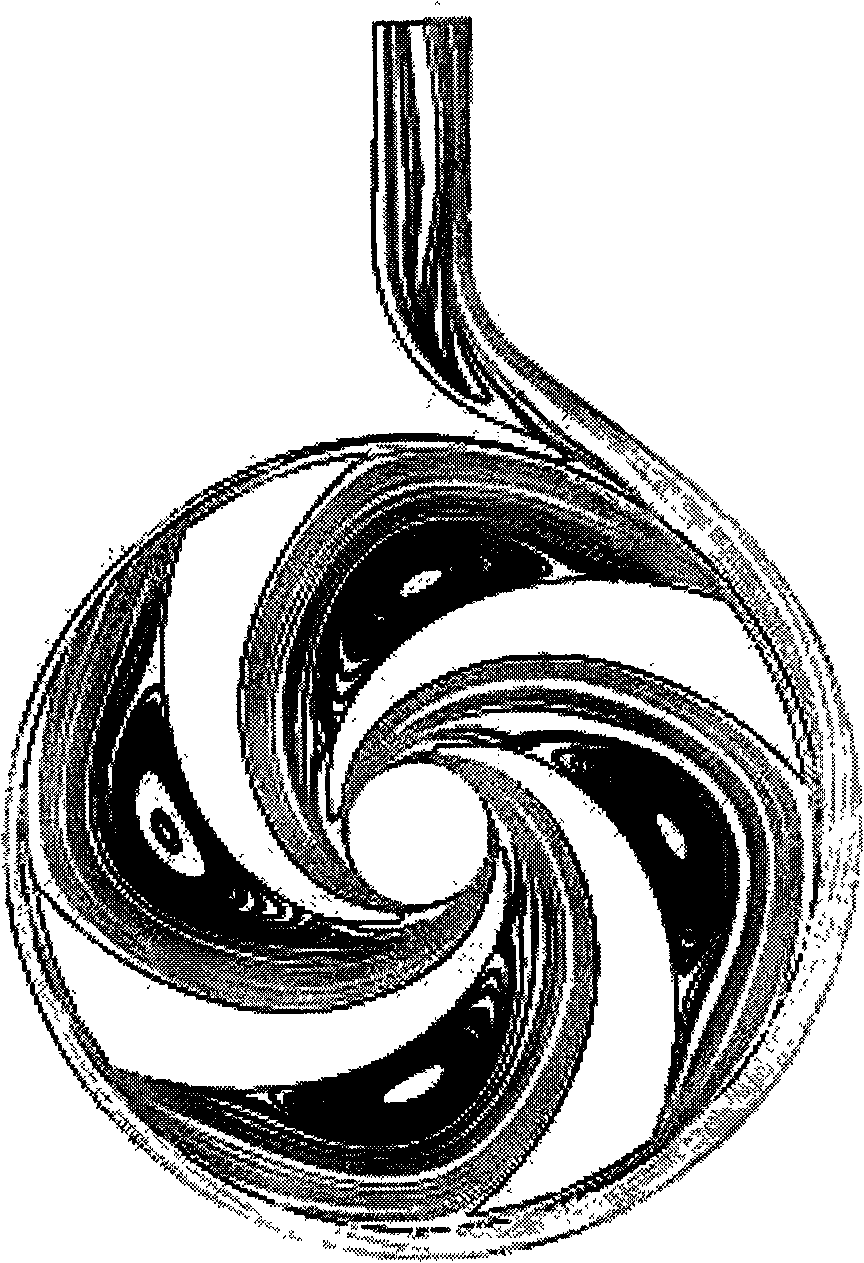

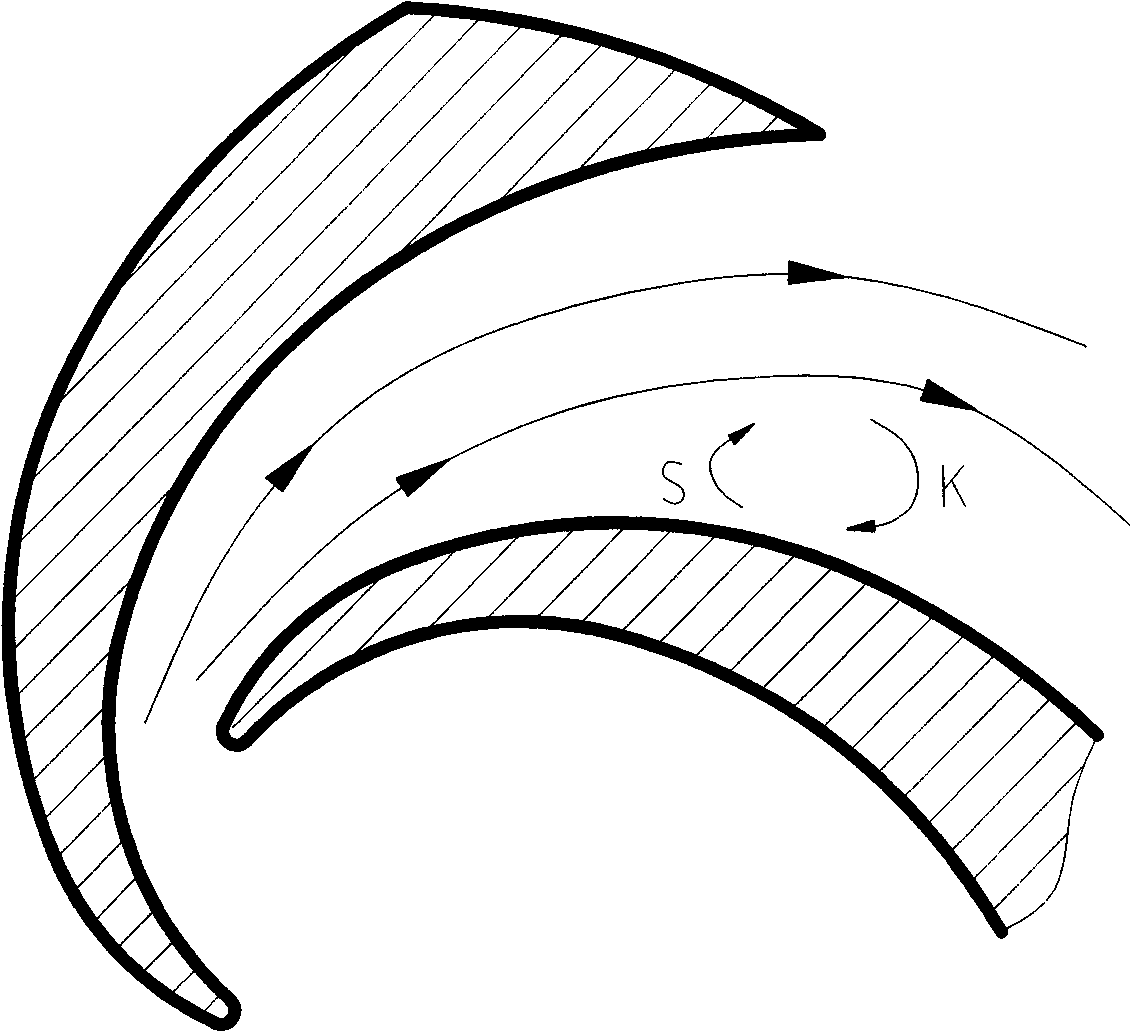

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

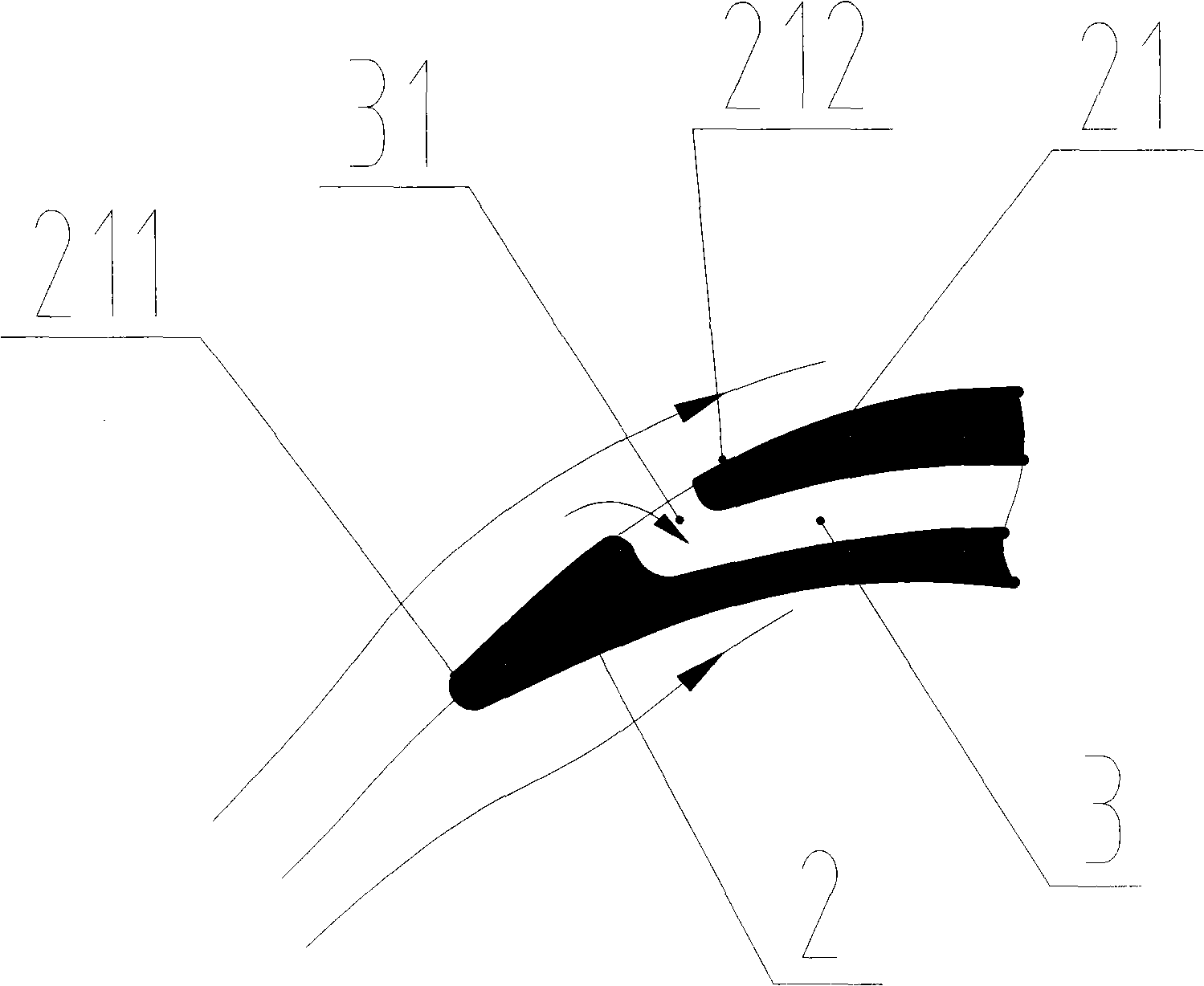

[0017] see image 3 and Figure 4 , an impeller of a pump, including an impeller hub 1 connected to a pump shaft and blades 2 evenly distributed on the impeller hub 1 . The number of blades 2 is four, five or six, or other numbers, which are mainly set according to the design requirements of the pump. The position of the vane 2 in the impeller hub 1 and the shape and size of the vane 2 are no different from the existing pump impeller, which is not the focus of the present invention, and is very well known to those skilled in the art, so it will not be described in detail here describe. As the impeller of the centrifugal pump, it also includes a front cover plate 4 , which is connected and fixed with the blades 2 .

[0018] The pump impeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com