Two-tone painting method

A paint and primer technology, applied in the direction of coating, liquid coating device on the surface, pretreatment surface, etc., can solve the problem of unsatisfactory coating appearance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

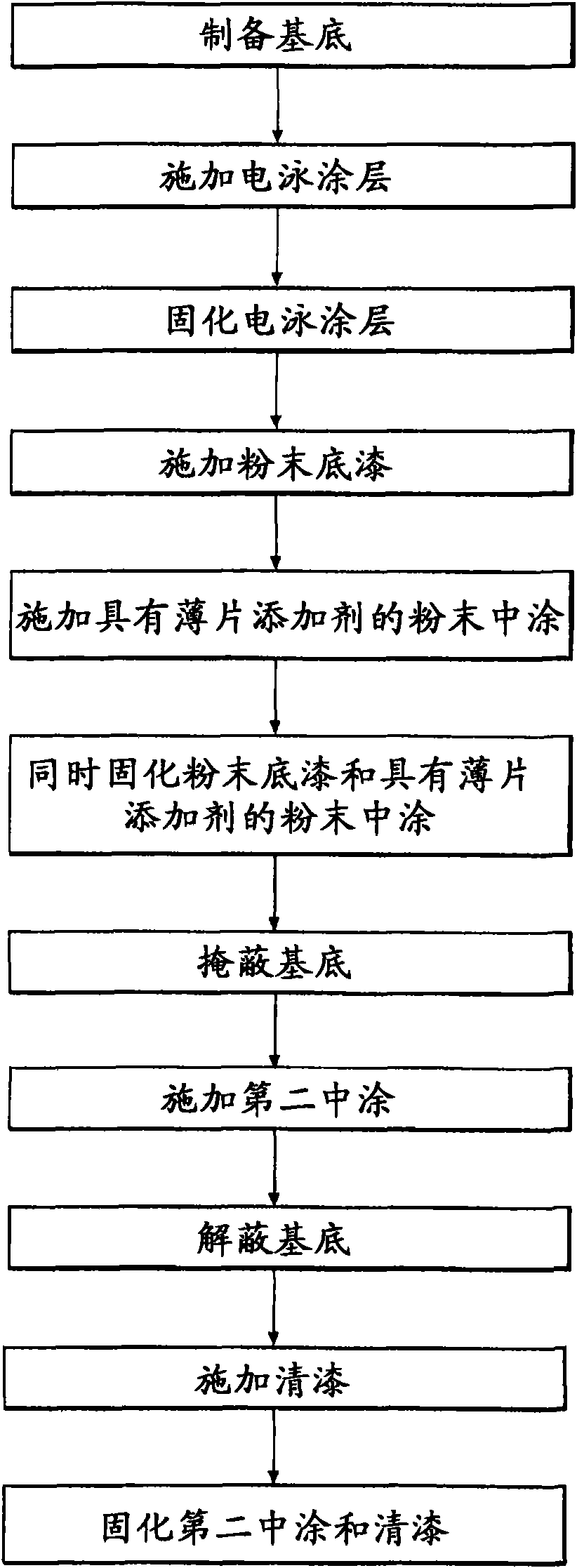

[0009] refer to figure 1 , generally illustrating a method of painting a substrate. The method includes applying a powder primer, a powder primer, and a topcoat to a substrate.

[0010] Although not required, the powder primer is preferably a low density powder primer. Thus, it should be understood that standard powder primers or low density powder primers may be used in accordance with the present invention. A powder primer includes a pigment component and a binder component. These ingredients may have ratios of pigment to binder known in the art. The pigment component has a higher weight per unit volume than the binder component. Thus, when the pigment component is reduced relative to the binder component, the total weight of the powder primer per unit volume is reduced. Thus, low density powder primers comprise a higher binder content relative to pigment content than is normally used in standard powder primers. Typically, low density powder primers have less than 1.4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com