Water bottle cap with water sealing structure

A water-stop and water bottle technology, applied in the field of water bottle caps, can solve the problems of poor practicability and convenience, inconvenient portability of water bottles or water bottles, and inability of water bottle caps to meet consumer demand, etc., and achieves a simple structure and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

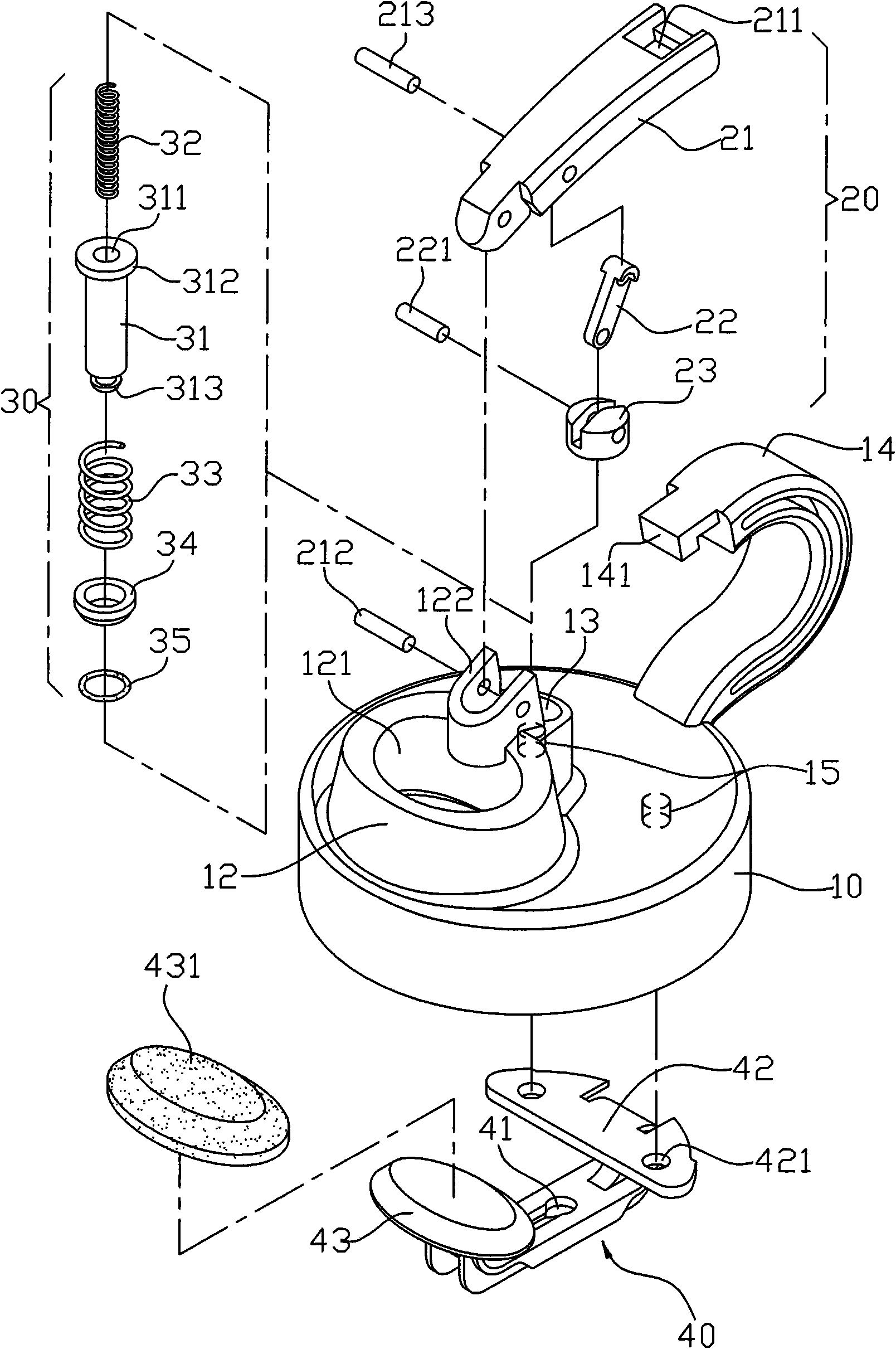

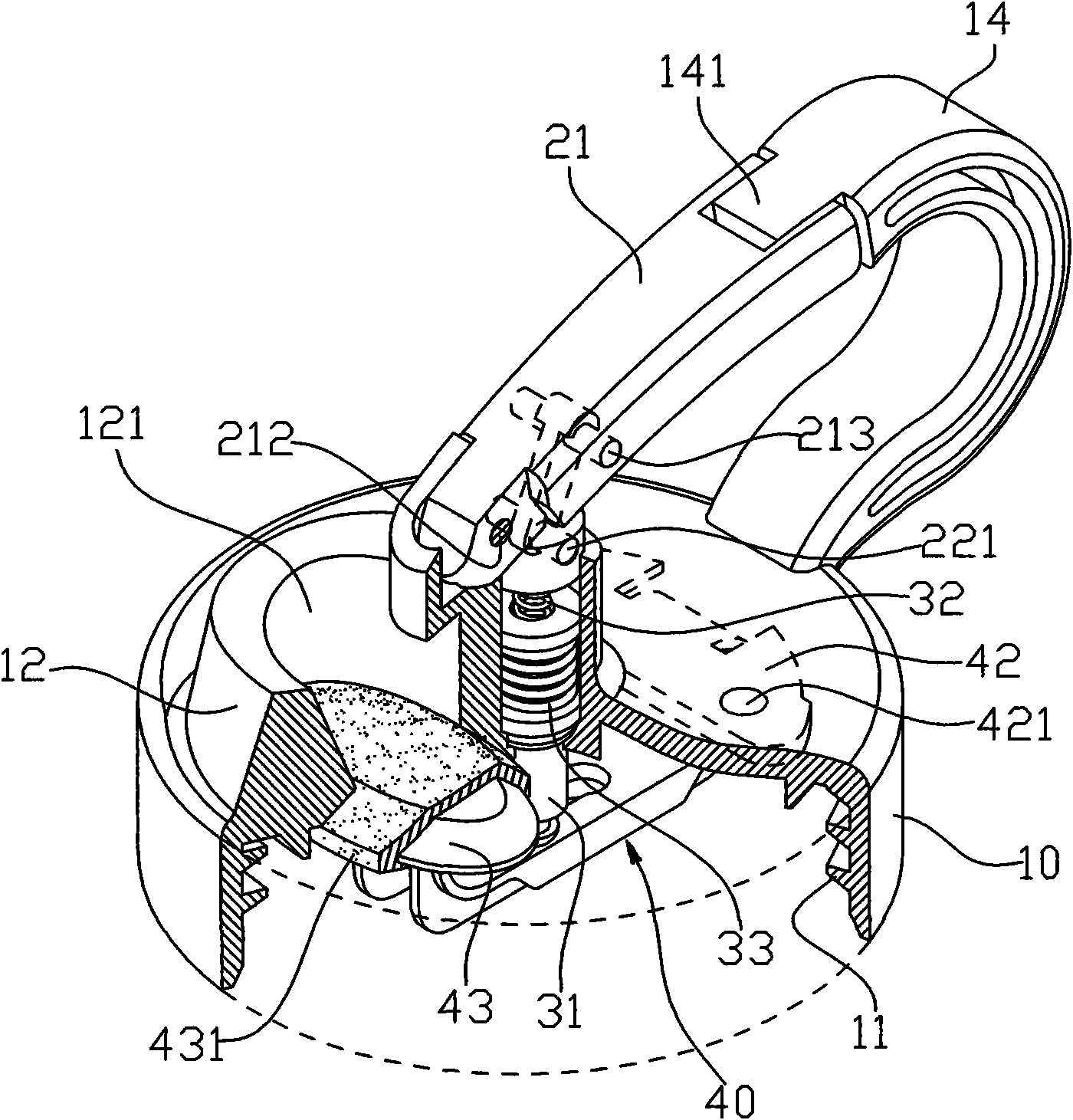

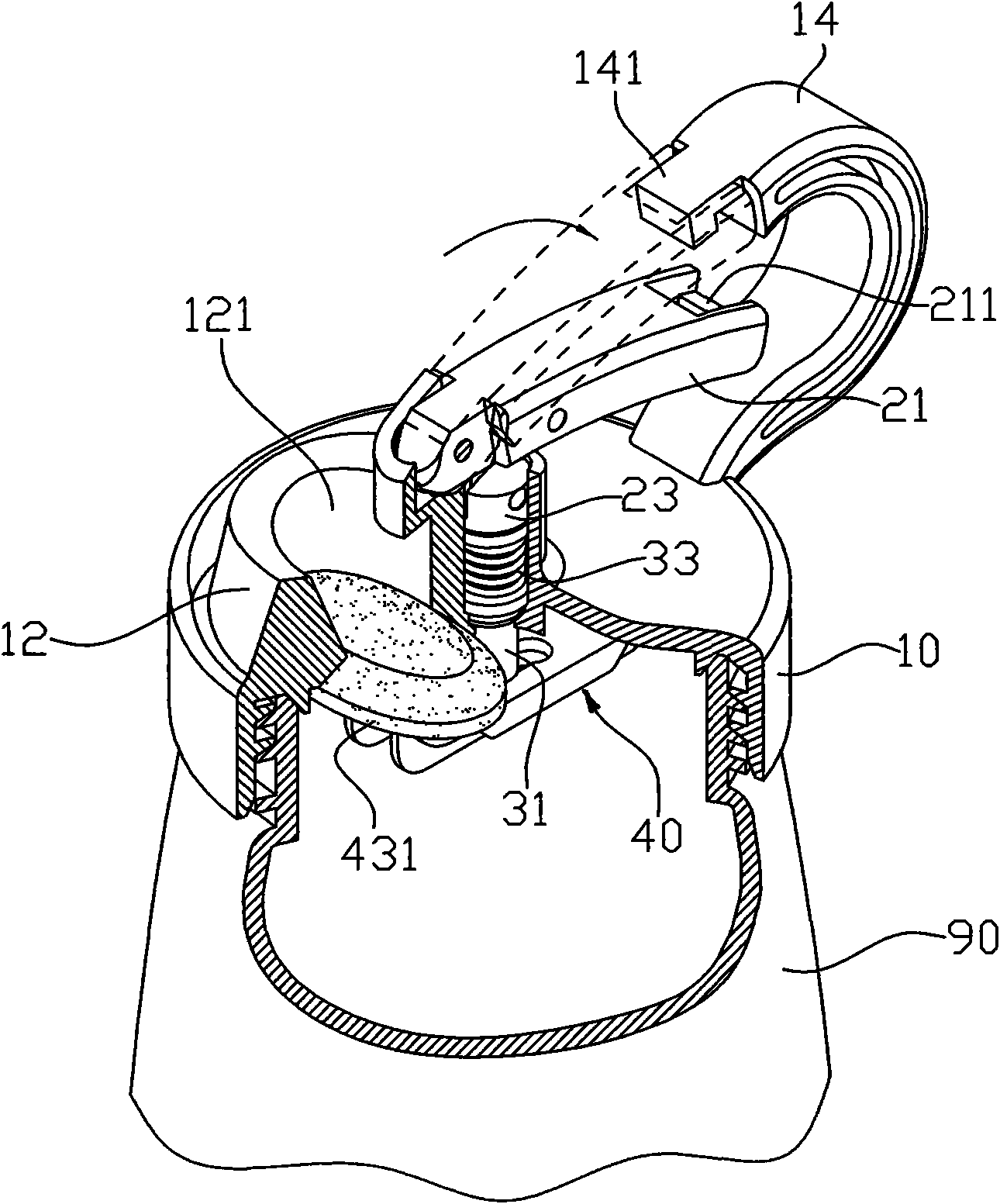

[0047] Such as Figure 1~4Shown is a water bottle cap with a water-stop structure of the present invention, including a body 10, a pressure bar device 20 for pressing, an elastic device 30 for controlling water discharge and water-stop, and an elastic device that can be controlled by the elastic force. The water stop 40 driven by the device 30, when in use, can drive the elastic device 30 to form a two-stage action by pressing the pressure rod device 20, so that the water stop 40 can only have the function when the pressure rod device 20 is pressed in the second stroke. water effect.

[0048] There is an internal thread 11 on the side inner wall of the body 10 (see figure 2 and 3 ), the outer surface of the bottle wall at the water outlet of the water container 90 has an external thread, and the internal thread 11 and the external thread are adapted for the body 10 to be installed on the water outlet of the water container 90 (see Figure 4 ), the top of the body 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com