Foam maker and foaming closestool

A technology for foaming devices and toilets, which can be used in flushing equipment with water tanks, sanitary equipment for toilets, flushing toilets, etc. It can solve the problems of slow foaming, complex structure of electric foaming system, easy damage and difficult repair, etc. Achieve the effect of fast foaming speed, simple structure and avoid power limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

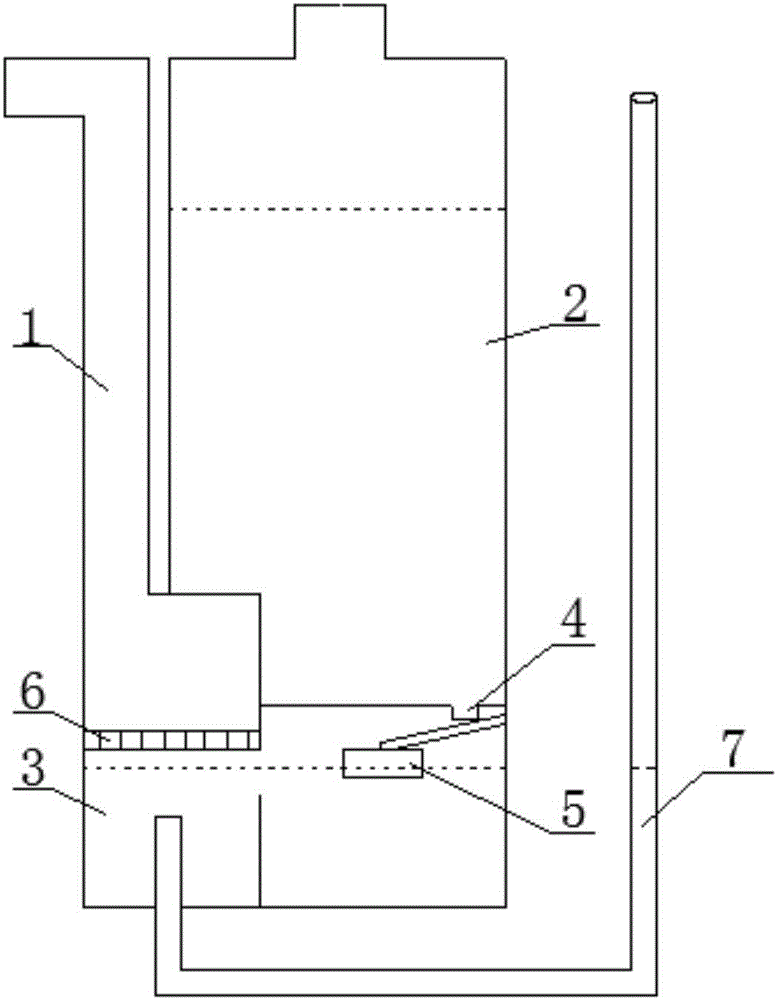

[0038] Such as figure 1 As shown, a foamer includes a foaming box, and the foaming box includes a foaming chamber 1, a storage chamber 2 for storing foam liquid, and a control chamber 3 for controlling the foaming of foam liquid, and the foaming chamber 1 and the storage chamber 2 are placed side by side on the upper end of the control chamber 3; the bottom of the storage chamber 2 is provided with a valve port 4 and it communicates with the control chamber 3 through the valve port 4; The valve port 4 is provided with a float valve 5 that controls the opening and closing of the valve port 4; the bottom of the foaming chamber 1 is provided with a foaming net 6 and communicates with the control chamber 3 through the foaming net 6; The control chamber 3 is provided with an air inlet pipe 7, and the foaming end of the air inlet pipe 7 is correspondingly below the foaming net 6, and is below the foam liquid level in the control chamber 3; its air inlet end protrudes The control ro...

Embodiment 2

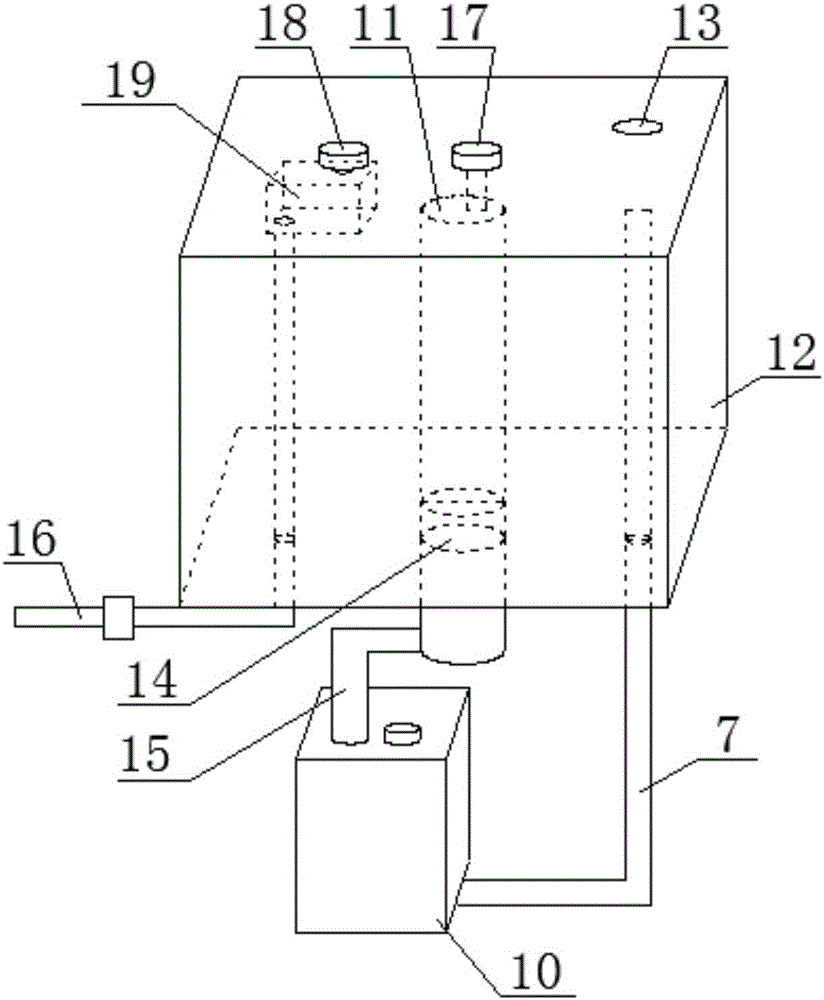

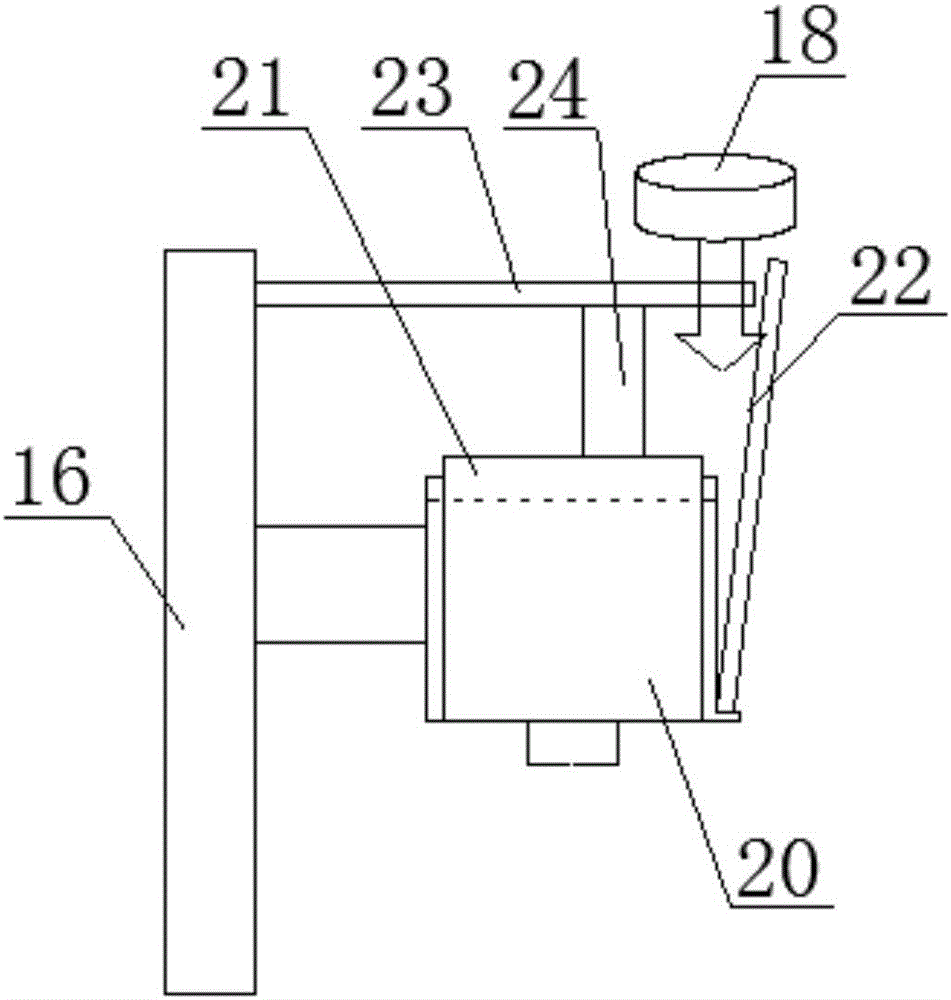

[0041] Such as Figures 2 to 4 As shown, a foam toilet includes a foamer 10, a flusher 11 and a sealed water tank 12, the flusher 11 is placed in the sealed water tank 12, and the top of the sealed water tank 12 is also provided with a single To the intake valve 13; the bottom of the sealed water tank 12 is provided with a first through hole 14 leading to the urinal, the water outlet of the flusher 11 communicates with the first through hole 14, and the bubbler The foaming chamber 1 of 10 communicates with the first through hole 14 through the bubble guiding tube 15; The level of the inlet end of 7 is higher than the water level in the sealed water tank 12; the lower end of the sealed water tank 12 is provided with a water inlet pipe 16 communicating with it, and the water inlet pipe 16 communicates with an external water source.

[0042] In the above embodiment, the water inlet pipe 16 injects water into the sealed water tank 12, which can compress the air in the sealed wate...

Embodiment 3

[0054] Such as Figure 7 As shown, a foaming toilet includes a foamer 10, a flusher 11 and a sealed water tank 12, the foamer 10 is placed in the sealed water tank 12, and the top of the sealed water tank 12 is provided with a foam injector The second through hole 25 for liquid, the storage chamber 2 of the foamer 10 communicates with the second through hole 25 through a pipe; the flusher 11 is placed in the sealed water tank 12, and the sealed water tank 12 The top of the tank is also provided with a one-way intake valve 13; the bottom of the sealed water tank 12 is provided with a first through hole 14 leading to the urinal, and the water outlet of the flusher 11 communicates with the first through hole 14 , the foaming chamber 1 of the foamer 10 communicates with the first through hole 14 through the bubble guiding tube 15; , and the level of the air inlet end of the air inlet pipe 7 is higher than the water level in the sealed water tank 12; Water connection.

[0055] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com