Storage-transportation integrated station device for random winding of high-power motor

A high-power, high-station technology, applied in the direction of transportation and packaging, packaging, and delivery of filamentous materials, can solve the problems of damaged winding wires, inter-turn insulation, extrusion and wear, and heavy coil weight, etc., to achieve manufacturing costs Reduced, easy to disassemble and reduce the effect of inter-turn insulation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

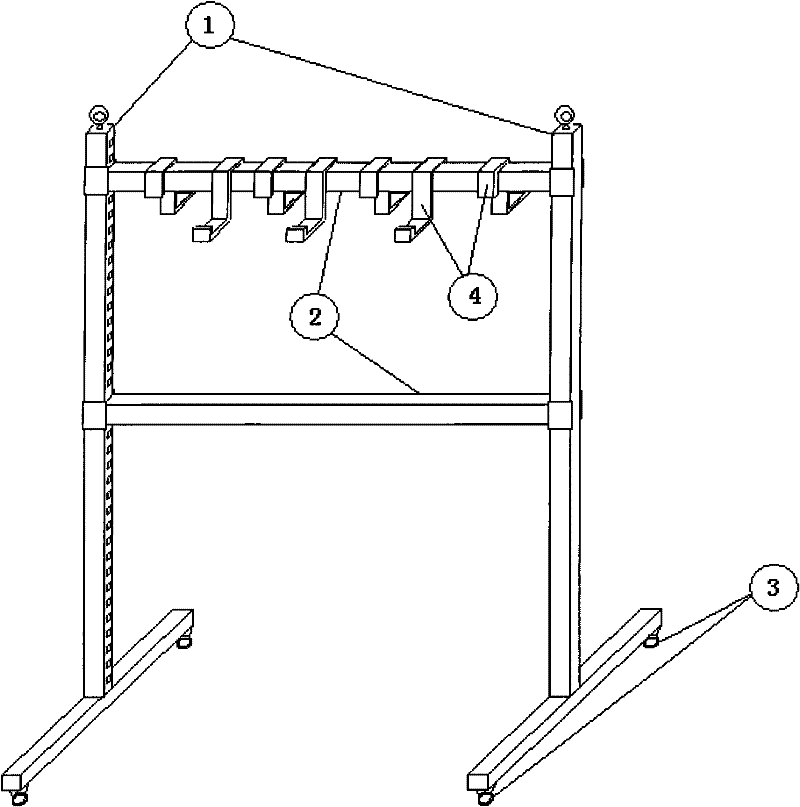

[0015] refer to figure 1 , which is a schematic diagram of an integrated station equipment for storage and transportation of scattered embedded windings of high-power motors according to the present invention.

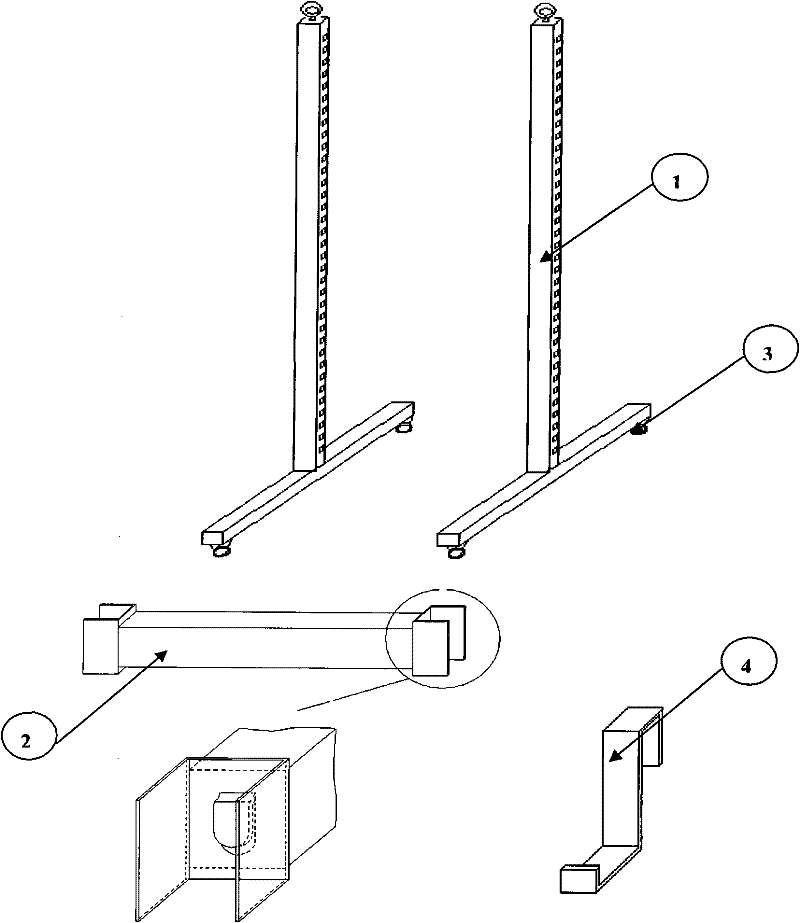

[0016] As shown in the figure, this equipment includes two support bases 1 at the uppermost end, two beams 2, and four universal wheels 3 at the lowermost end of the support base 1; Several coil frames 4 are installed on the 2, and any two coil frames 4 form a group of coil hangers.

[0017] Because the coil frame 4 is in plane contact with the beam 2 and the lateral force is very small, the coil frame 4 will not move laterally, and the front and rear will not be displaced front and rear due to being embedded on the square tube. The distance between the two bobbins 4 can be adjusted arbitrarily with the size of the coil without fixing.

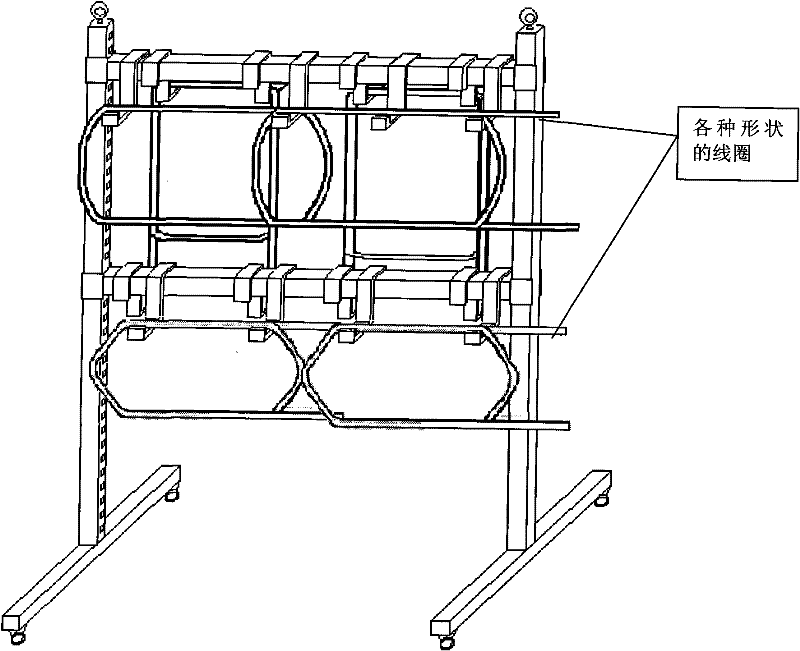

[0018] One station equipment can use multiple coil frames 4 at the same time on the upper and lower beams and the front and back si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com