Self-adjusting mechanism of two leading shoe brake of automobile

A technology of brakes and leading shoes, applied in the direction of slack adjusters, etc., can solve the problems of tedious work and manual adjustment of automobile brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

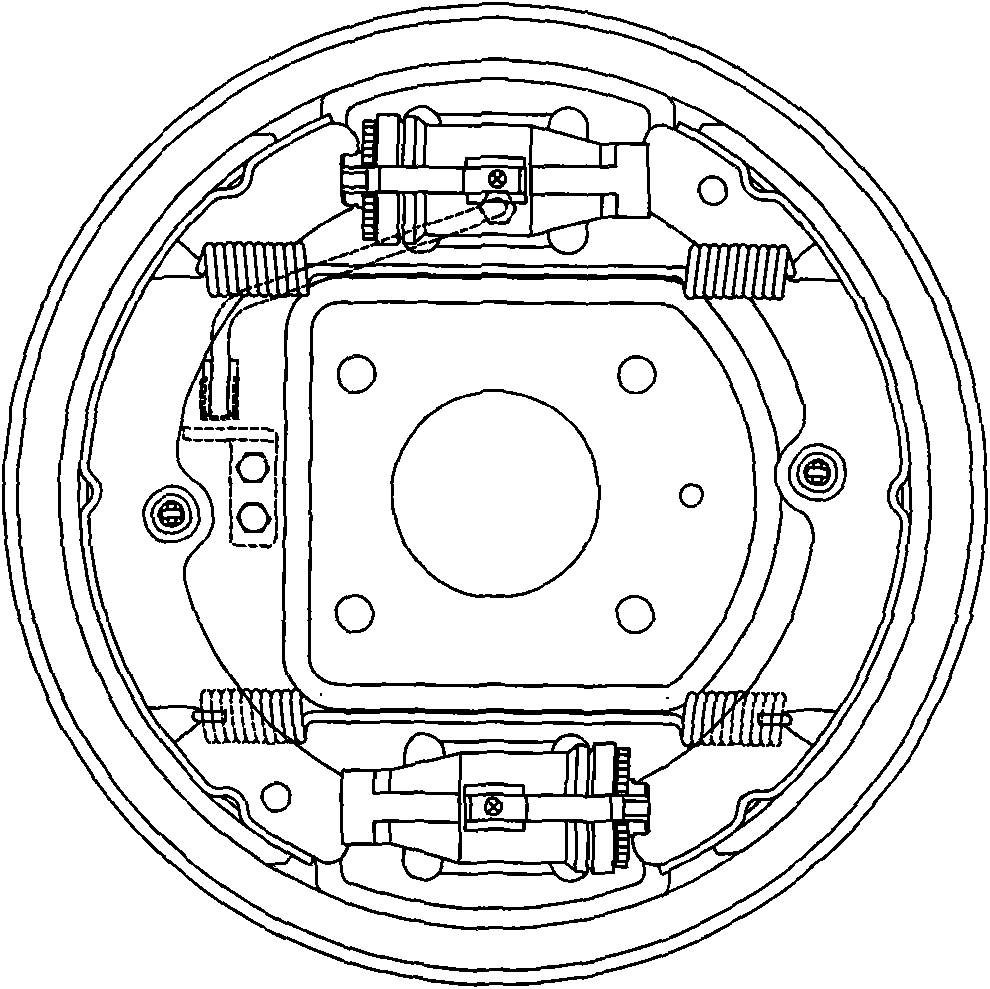

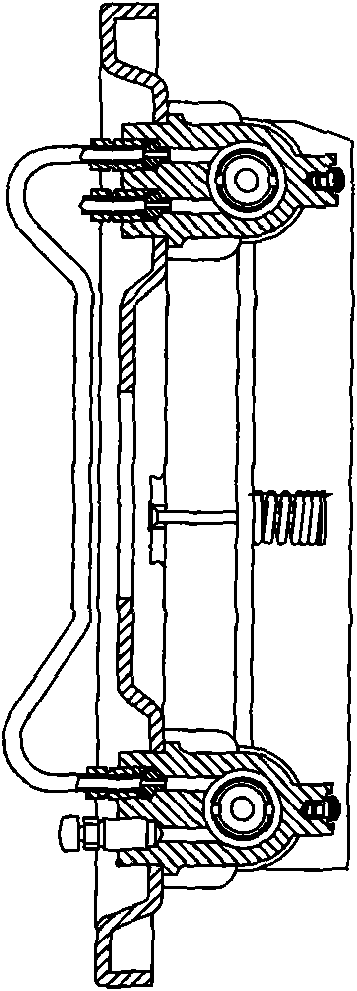

[0027] Such as Figure 1-4 As shown, the double-collar shoe brakes currently on the market do not use a gap self-adjusting mechanism.

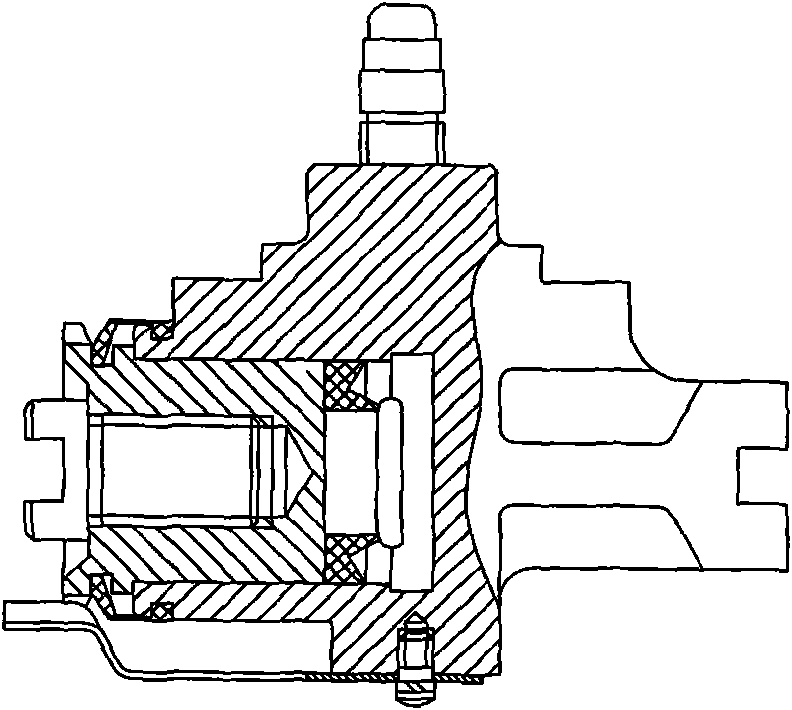

[0028] Such as Figure 5-12 As shown, a self-adjusting mechanism for an automobile double-collar shoe brake disclosed by the present invention is installed on a piston 6 and a wheel cylinder block 5 connected to the piston 6, and includes a gap pick 1, a ratchet 7 and a tension spring 3. The gap plectrum 1 is installed on the piston 6 through the positioning bolt 4, the gap plectrum 1 is engaged with the ratchet 7, the other end of the gap plectrum 1 is connected with the tension spring 3 connected to the gap support plate 2, the gap The support plate 2 is fixed on the piston 6 ; the ratchet 7 is fixed on the adjusting bush 8 , and the adjusting bush 8 is installed in the wheel cylinder body 5 .

[0029] In addition, an adjustment screw 10 is also provided, which is connected with the adjustment bush 8, and then the ratchet 7 is fixed; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com