Detector for judging mounting height of pointer and detection method thereof

A technology of installation height and pointer, which is applied in the field of inspection tools for judging the installation height of the pointer and its inspection field, can solve the problems of cumbersome measurement steps, easy misjudgment, large measurement error, etc., and achieve simple structure, easy judgment, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

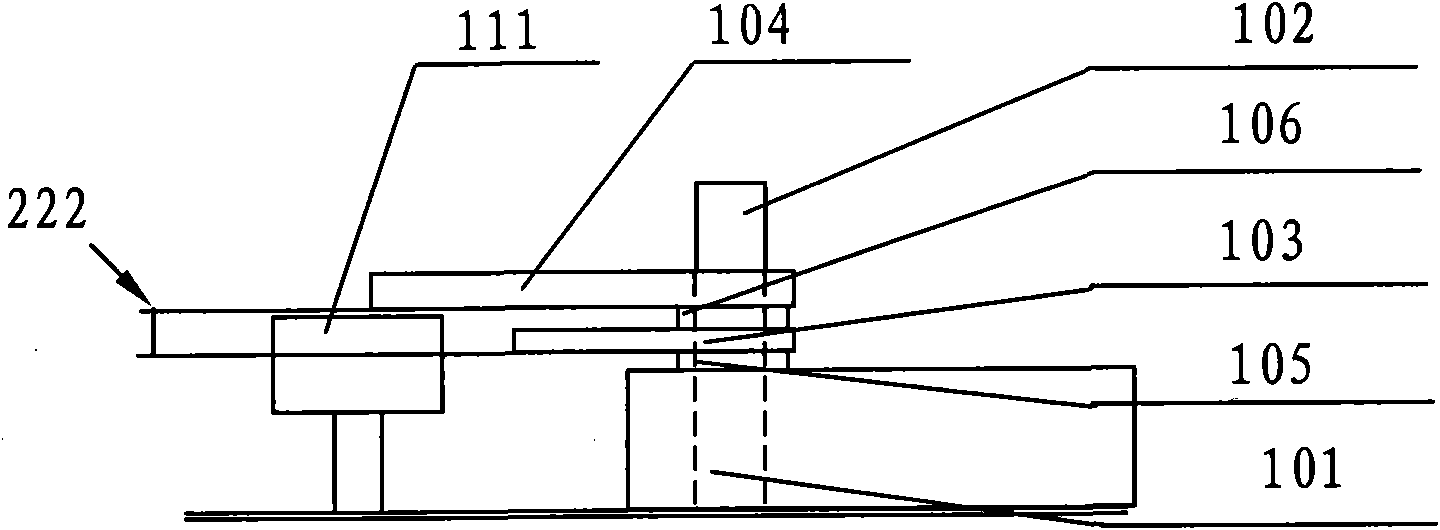

[0036] The height of the pointer 111 to be measured is 7±0.3, and the following steps are performed for detection:

[0037] Step 1. The base and the connecting rod are assembled together to form a reference measuring seat;

[0038] Step 2. Since the minimum installation height is 6.7mm and the difference from the base is 0.2mm, add the first standard plug piece with a thickness of 0.2mm to the connecting rod;

[0039] Step 3. Set the reference gauge block on the connecting rod;

[0040] Omit step 4;

[0041] Step 5, install the upper limit block on the connecting rod;

[0042] Step 6. Perform detection; visually check whether the height of the pointer is figure 1 The shown detection qualified area 222 is within the error range; judge whether it is qualified or not;

Embodiment 2

[0044] The height of the pointer to be measured is 7±0.5, and the following steps are performed for detection:

[0045] Step 1. The base and the connecting rod are assembled together to form a reference measuring seat;

[0046] Omit step 2;

[0047] Step 3. Set the reference gauge block on the connecting rod;

[0048] Step 4. Since the upper and lower limit error is 1mm, and the difference from the reference gauge block is 0.4mm, a second standard plug piece with a thickness of 0.4mm is added to the connecting rod;

[0049] Step 5, install the upper limit block on the connecting rod;

[0050] Step 6. Perform detection; visually check whether the height of the pointer is figure 1 The shown detection qualified area 222 is within the error range; judge whether it is qualified or not;

Embodiment 3

[0052] The height of the pointer to be measured is 8±0.5, and the following steps are performed for detection:

[0053] Step 1. The base and the connecting rod are assembled together to form a reference measuring seat;

[0054] Step 2. Since the minimum installation height is 7.5mm and the difference from the base is 1mm, add the first standard plug piece with a thickness of 1mm to the connecting rod;

[0055] Step 3. Set the reference gauge block on the connecting rod;

[0056] Step 4. Since the upper and lower limit error is 1mm, and the difference from the reference gauge block is 0.4mm, a second standard plug piece with a thickness of 0.4mm is added to the connecting rod;

[0057] Step 5, install the upper limit block on the connecting rod;

[0058] Step 6. Perform detection; visually check whether the height of the pointer is figure 1 The shown detection qualified area 222 is within the error range; judge whether it is qualified or not.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com