Auxiliary tool for dismounting CPU

A jig and guide mechanism technology, applied in the jig field, can solve the problems of easily damaged CPU pins, difficult to pull out the CPU horizontally, and scrapped electronic components, etc., to achieve the effect of improving the efficiency of functional testing and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

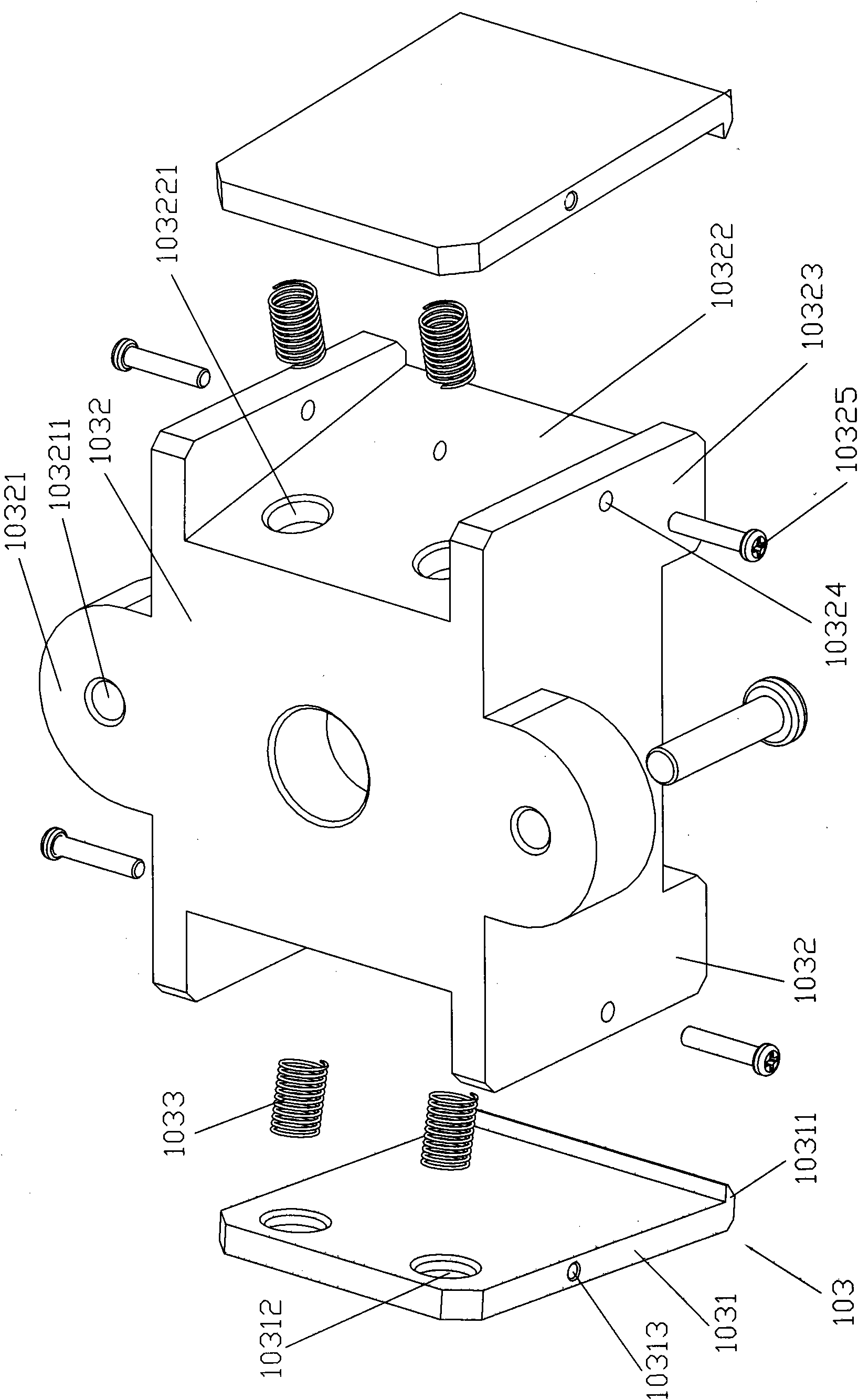

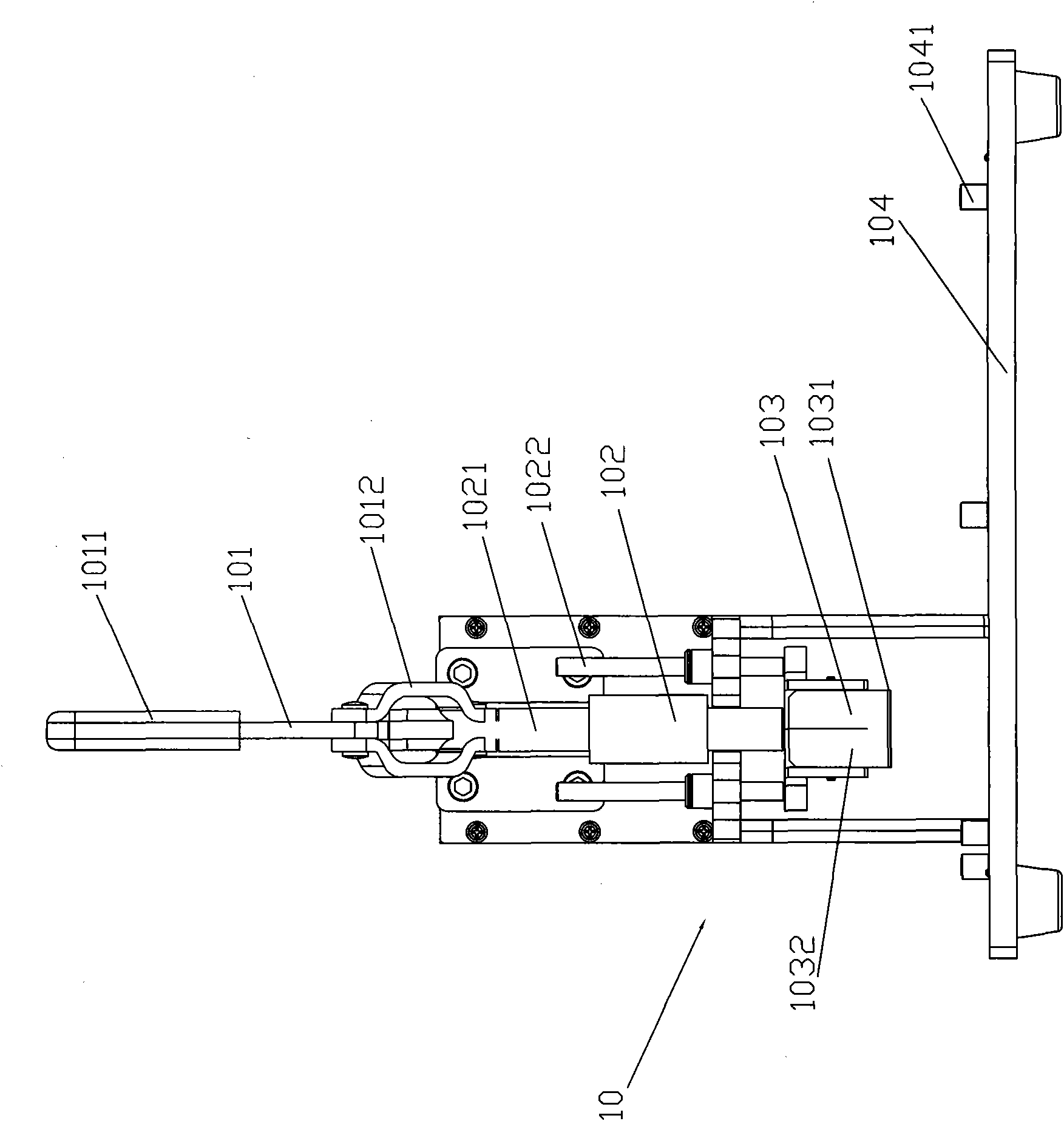

[0013] Please also refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown. The auxiliary dismantling CPU jig 10 described in the present invention is mainly suitable for disassembling the CPU on the main board 20 to be tested after a main board 20 to be tested has been functionally tested. The auxiliary dismantling jig 10 mainly includes a movable mechanism 101, A guiding mechanism 102 , a clamping mechanism 103 and a fixing base 104 .

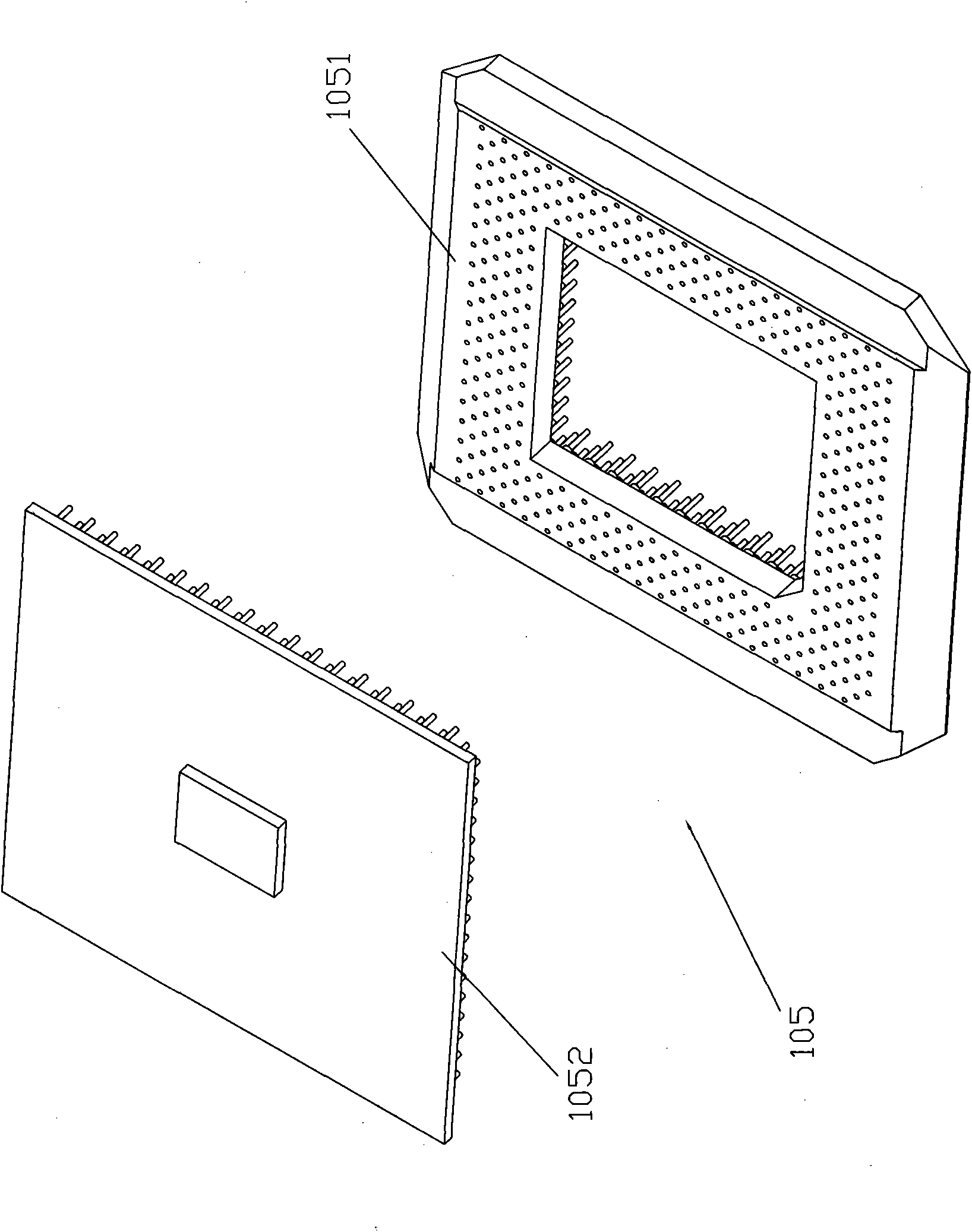

[0014] Wherein, the fixed base 104 is provided with a receiving groove (not shown in the figure) and a plurality of holding parts 1041 arranged around the receiving groove, and the holding parts 1041 can be movably rotated on the surface of the fixing base 104, A number of positioning pins (not shown) are arranged in the accommodating groove for placing the main board 20 to be tested and using the positioning pins therein to fix the main board 20 to be tested. Rotate the holding part 1041 by hand, Until the pressing por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com