Electrode device and electromachining method

An electrode device and electric processing technology, applied in the direction of electric processing equipment, processing electrodes, electrode manufacturing, etc., can solve the problems of low processing efficiency and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

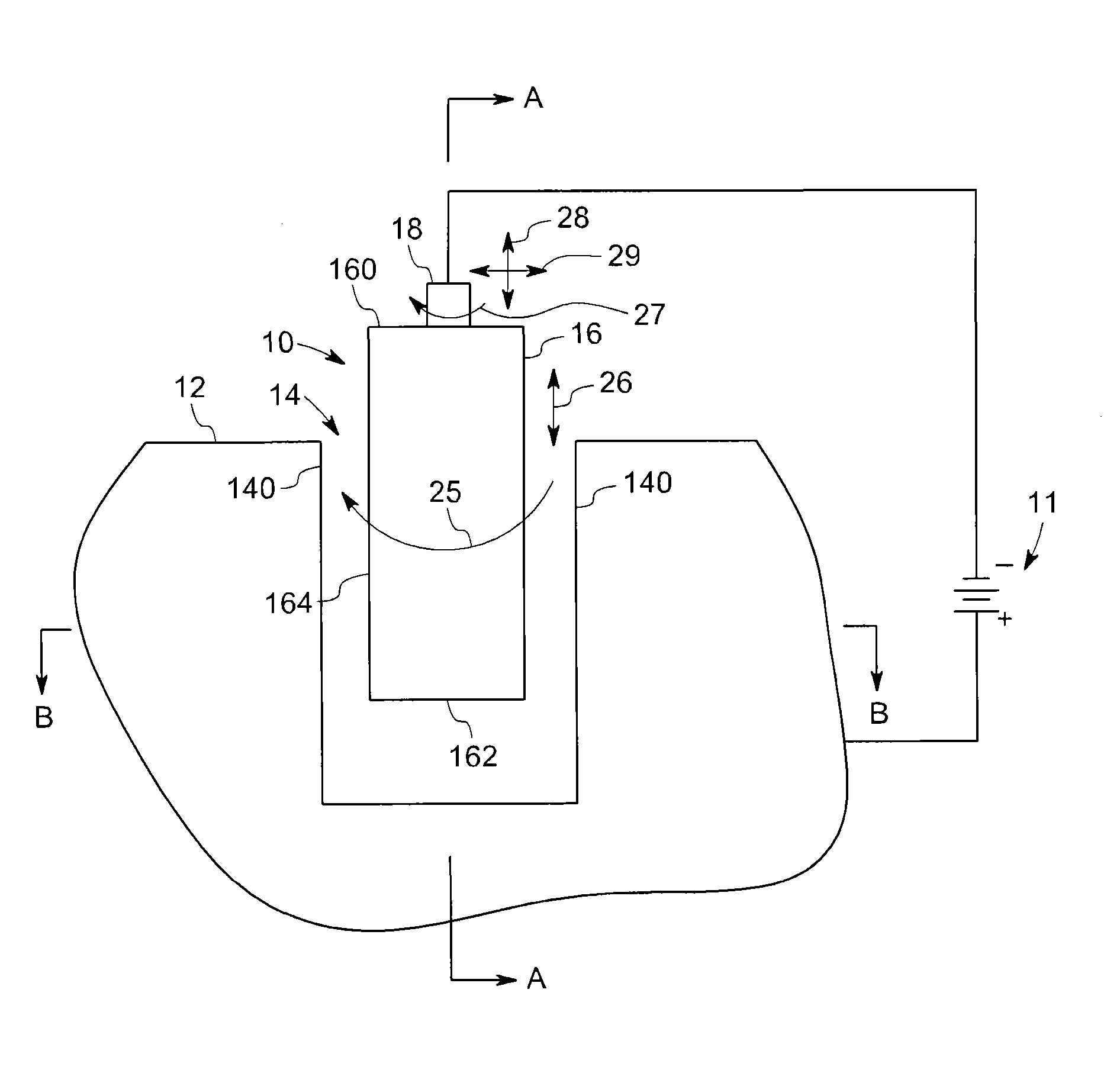

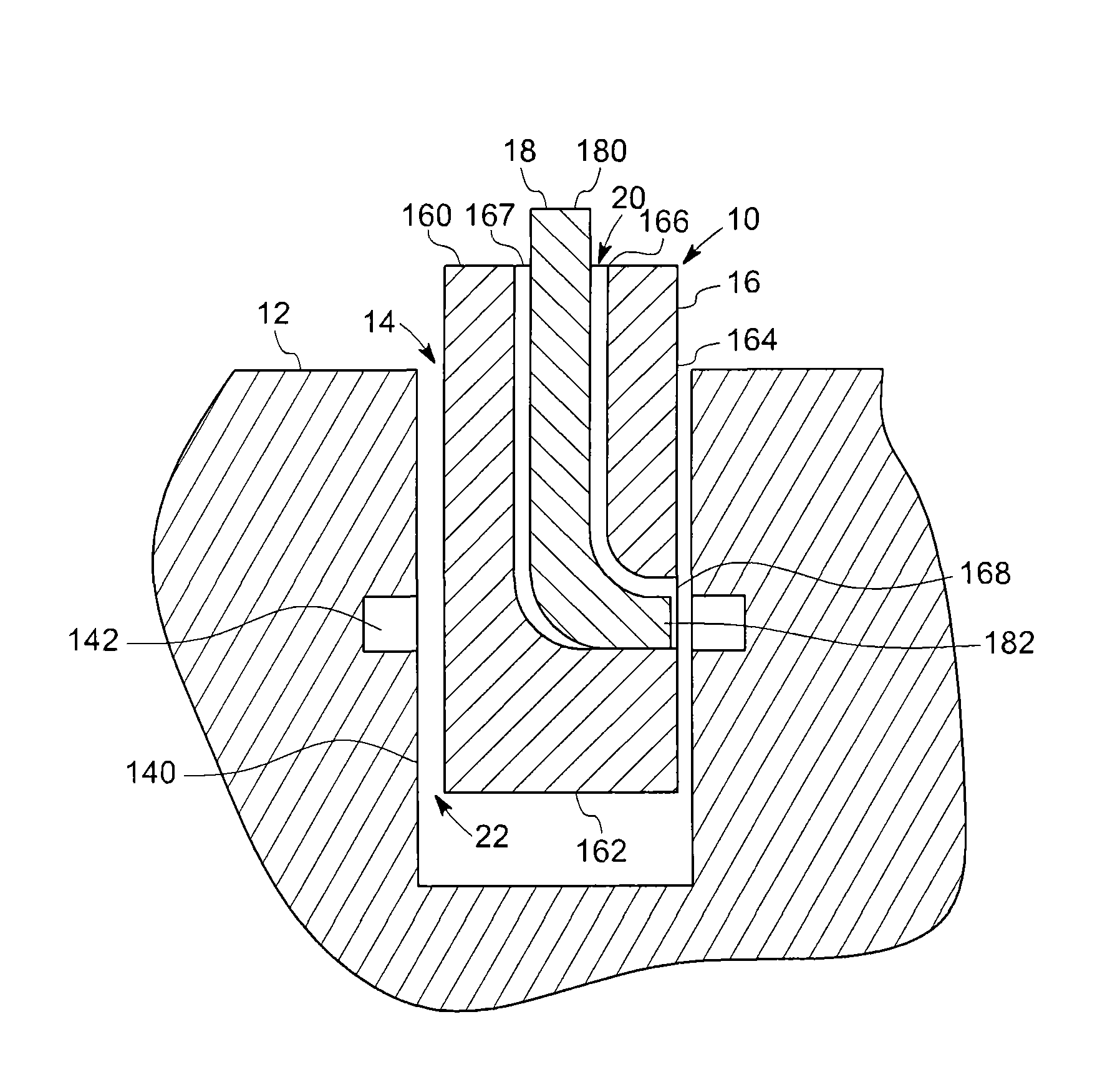

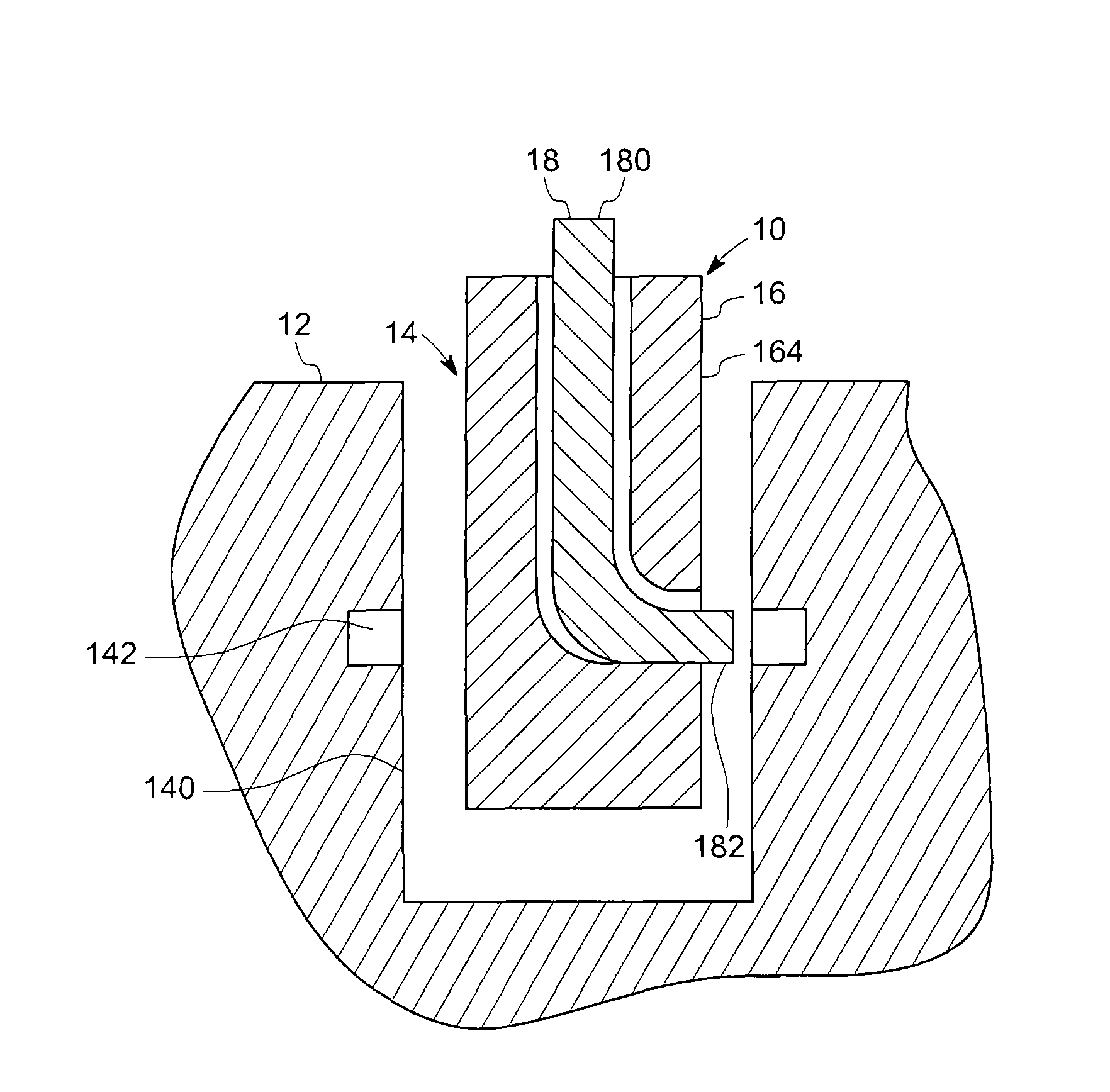

[0018] like figure 1 As shown, the electrode device 1 includes an electrode 10, a power source 11 and a machining fluid source (not shown). The electrode 10 is disposed within a bore 14 of a conductive workpiece 12 and includes a tubular element 16 and a conductive element 18 received within the tubular element 16 . The tubular element 16 is provided with an upper surface 160 , a bottom surface 162 and a side 164 between the upper surface 160 and the bottom surface 162 . The conductive element 18 includes a front end 180 positioned outside the upper surface 160 and a rear end 182 ( figure 2 shown). The positive pole and the negative pole of the power supply 11 are respectively connected to the workpiece 12 and the front end 180 of the conductive element 18 . In addition, in some embodiments, the positive pole and the negative pole of the power source 11 may also be connected to the front end 180 of the conductive element 18 and the workpiece 12 respectively. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com