Bulk paper board cutting tool

A technology for cutting knives and cardboard, applied in metal processing and other directions, can solve the problems of waste of social resources, large paper consumption, poor shock absorption effect, etc., and achieve the effect of saving social resources, small usage, and good shock absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

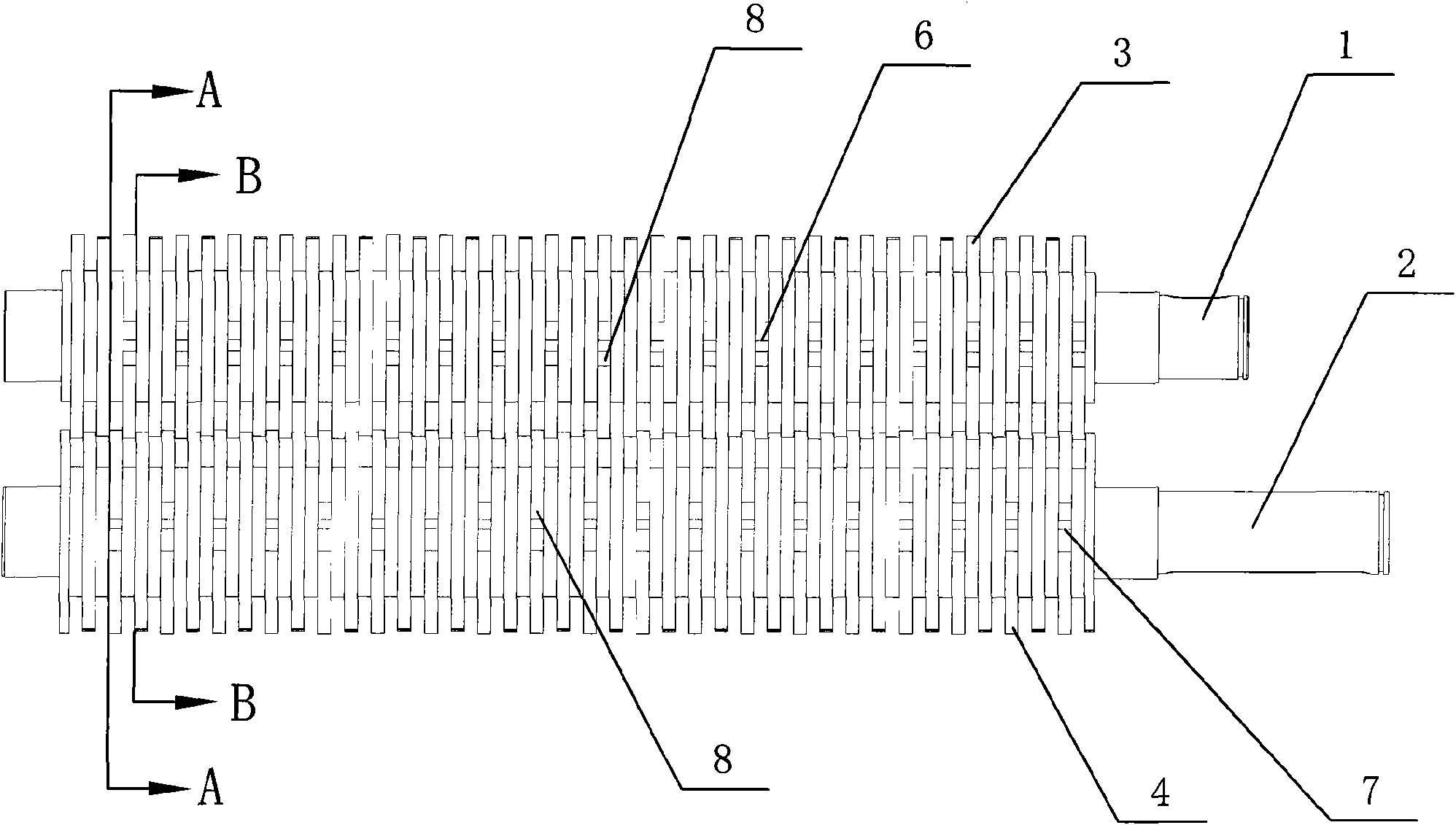

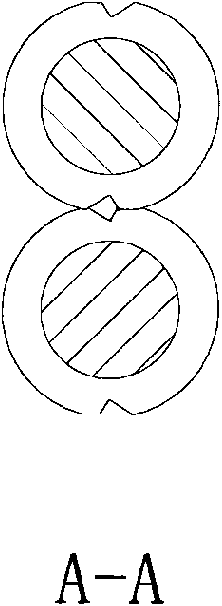

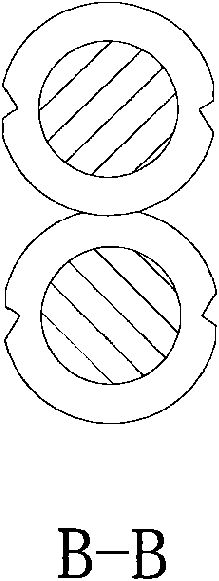

[0022] like figure 1 , figure 2 As shown, the bulky cardboard cutting tool of the present invention includes an upper cutter shaft 1 and a lower cutter shaft 2 which are installed on a support plate 5 and rotate in opposite directions, and a plurality of annular first blades 3 arranged on the upper cutter shaft 1 With a plurality of annular second blades 4 arranged on the lower cutter shaft 2, a plurality of first blades 3 are integrated with the upper cutter shaft 1, and a plurality of second blades 4 and the lower cutter shaft 2 are also integrated. All are processed by milling machine. The two ends of the upper cutter shaft 1 and the lower cutter shaft 2 are tightly fitted with bearings respectively, and the bearings are respectively fixed on the left and right support plates 5 . The first blades 3 and the second blades 4 are distributed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap