Ceramic powder feeding device and feeding method thereof

A technology of ceramic powder and blanking, which is applied to supply devices, manufacturing tools, etc., can solve the problems of different thickness of powder and uneven powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

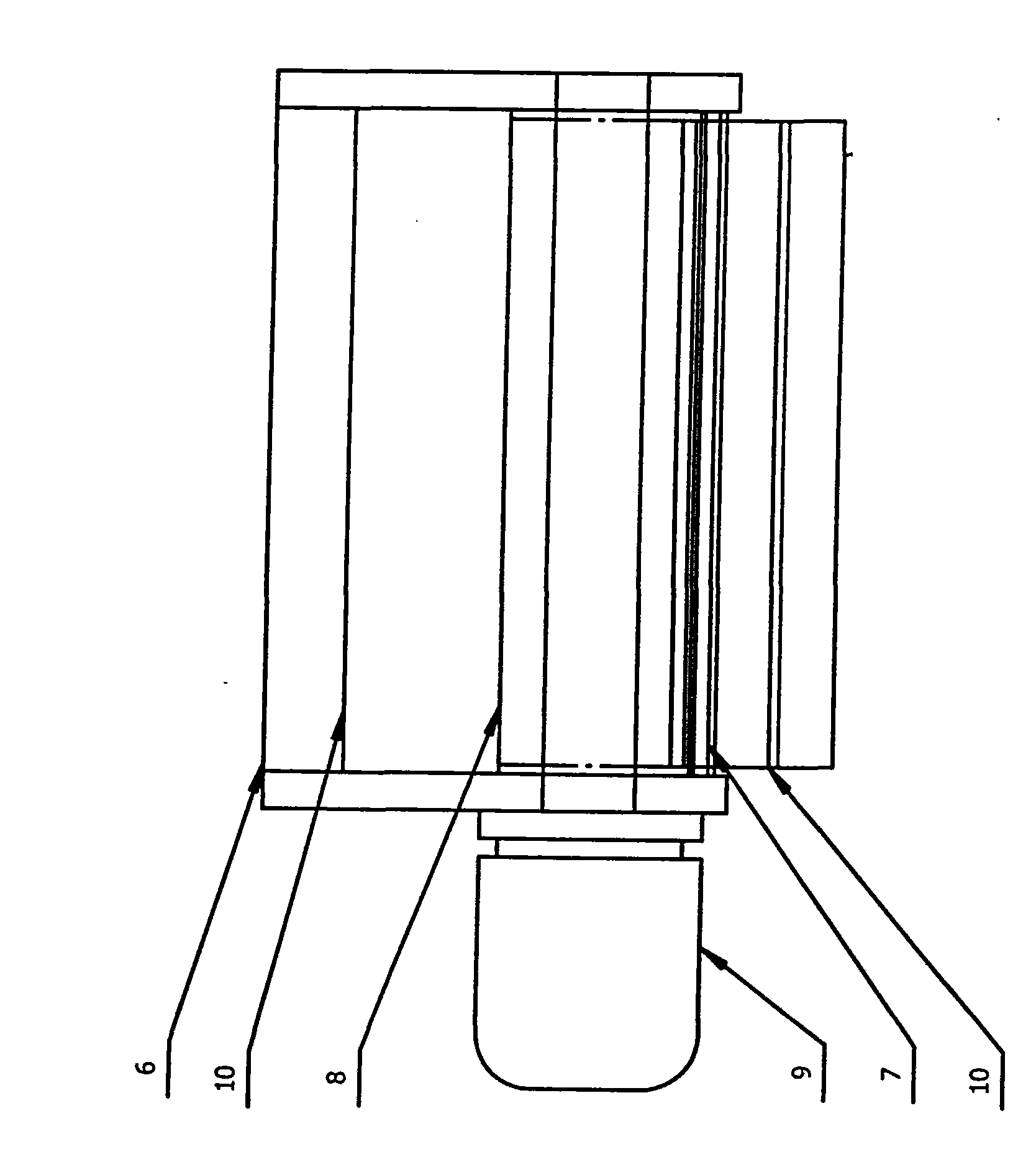

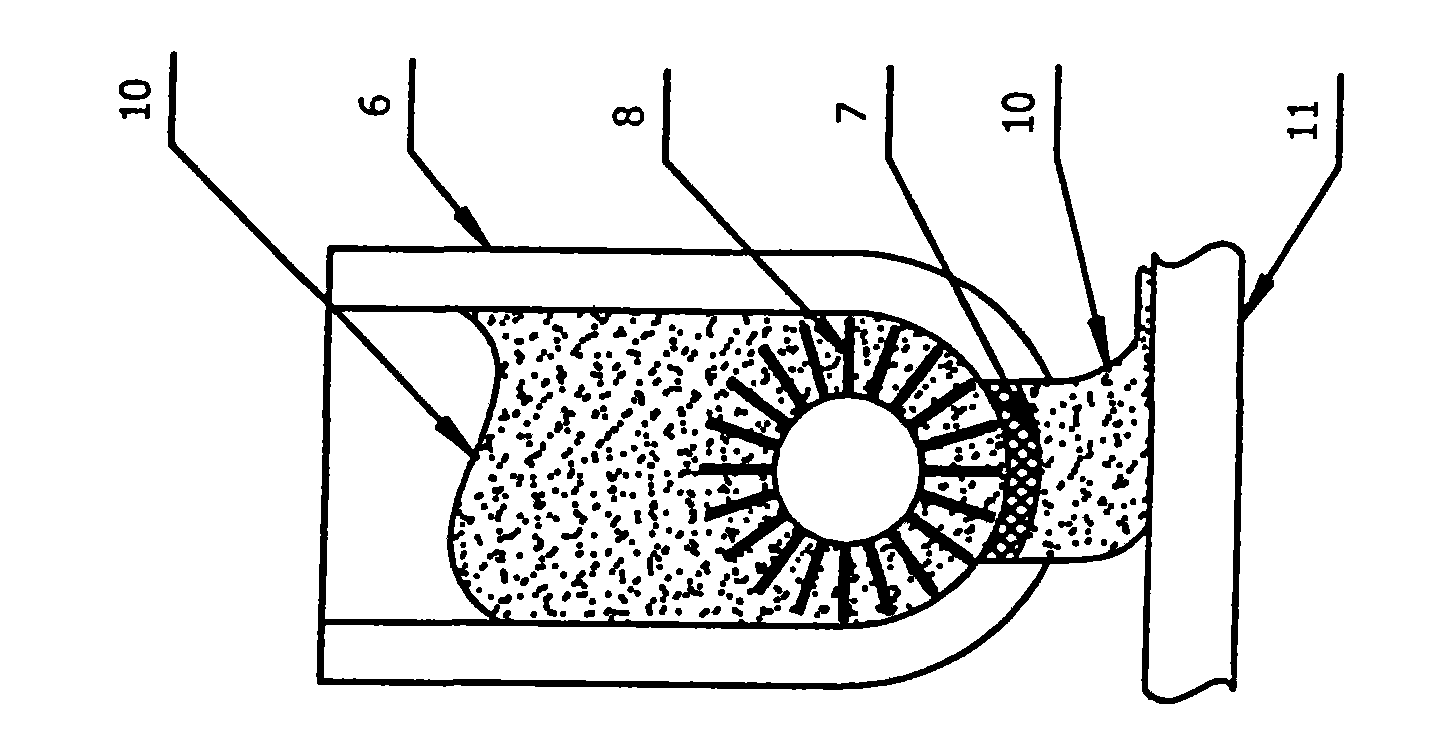

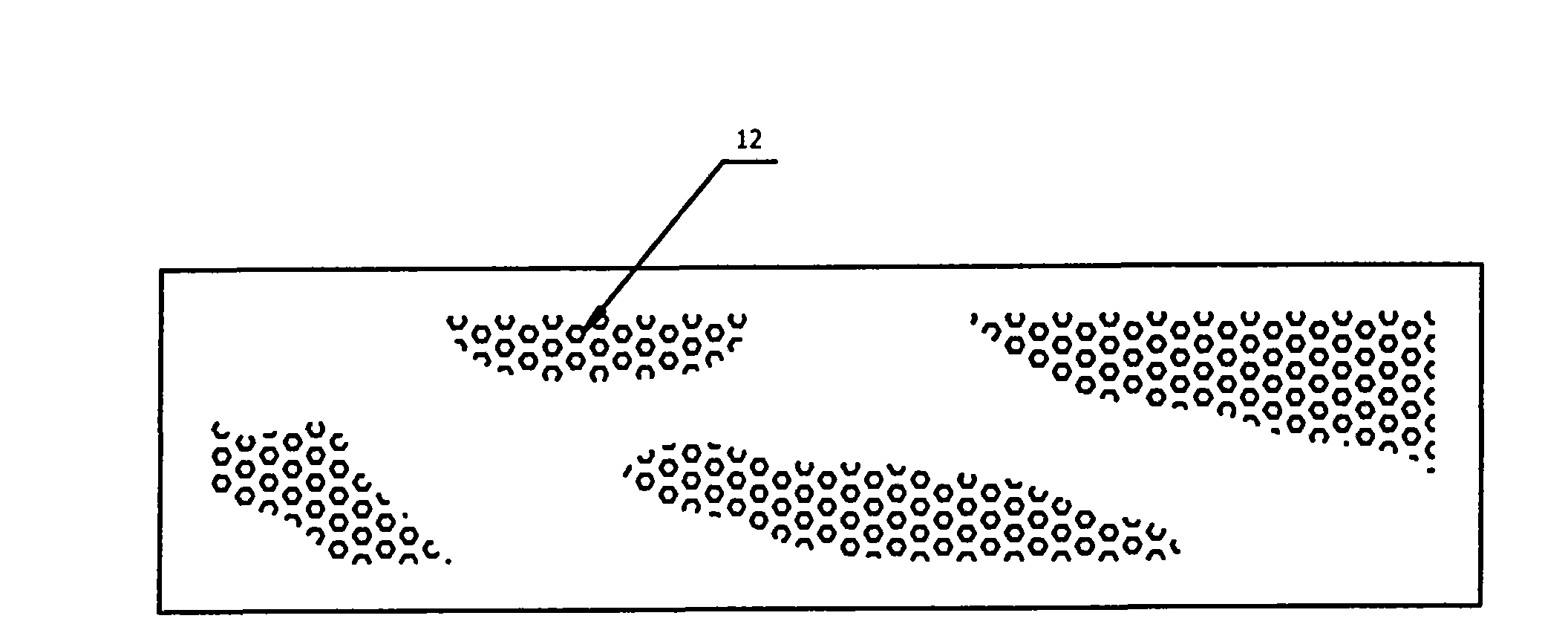

[0016] Such as Figure 1-Figure 4 As shown, in the present embodiment, first the blanking screen 7 is installed in the storage hopper 6, as image 3 As shown, the pattern of the blanking stencil 7 can be made according to the blanking pattern, and the stencil opening area 12 in the blanking stencil 7 is the stencil blanking area. Install the rotating hairbrush 8 in the storage hopper 6 again, the distance between the rotating hairbrush 8 and the blanking net plate 7 can be adjusted, then the rotating device 9 is installed on the rotating hairbrush 8, and the rotating device 9 is fixed. Put the ceramic powder 10 into the storage hopper 6, start the rotating device 9 to drive the rotating brush 8, and the ceramic powder 10 is evenly lowered to the carrier 11 under the rotation of the rotating brush 8 and according to the shape of the blanking screen 7 superior. Adjust the rotation speed of the rotating device 9 to control the feeding speed and the amount of feeding, change the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com