Powder filling machine with dust removal function

A filling machine and powder technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of increasing the distance between dust and the dust collection hood, high energy consumption, and affecting the dust collection effect, so as to avoid health problems, The effect of purifying the working environment and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

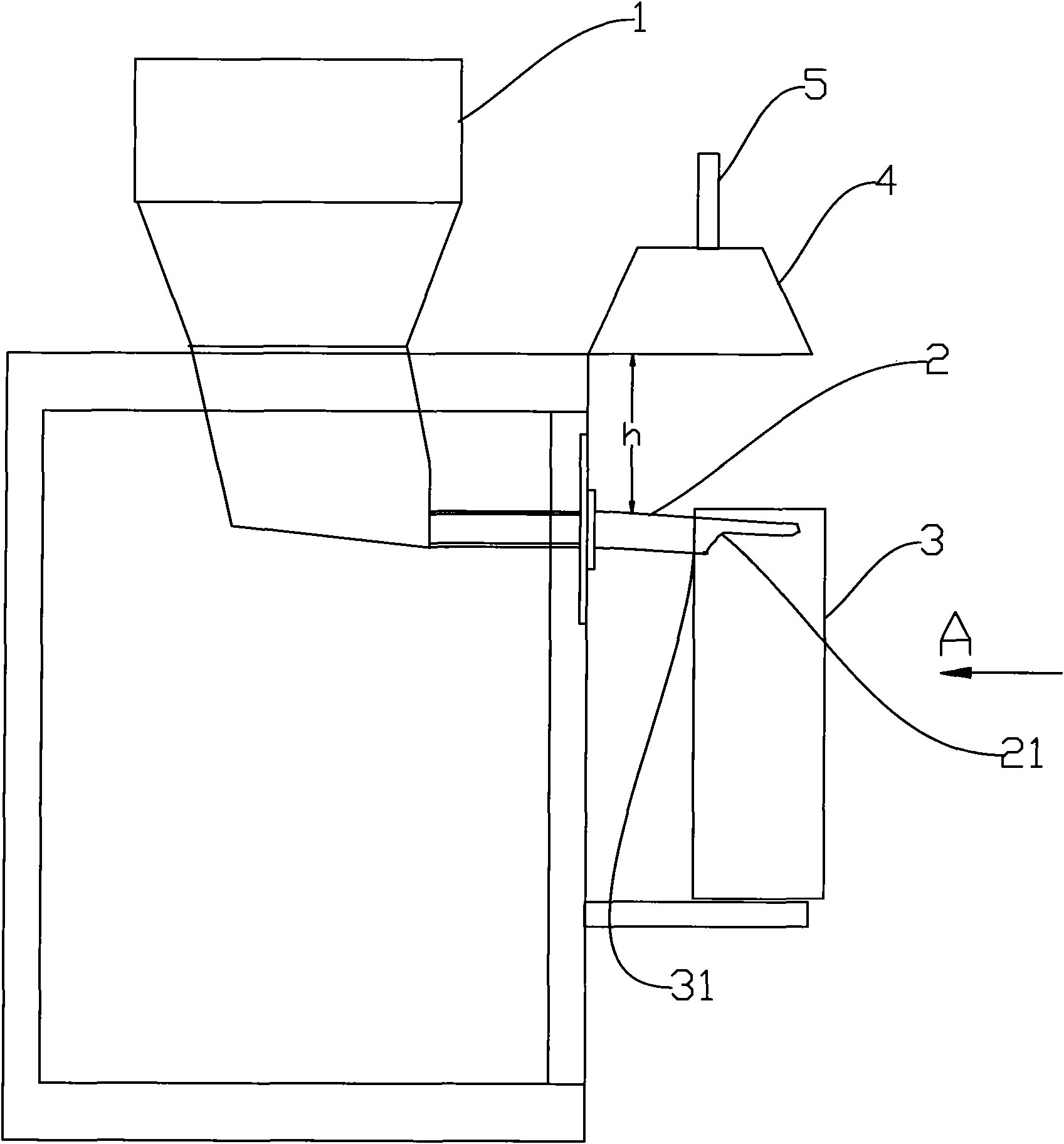

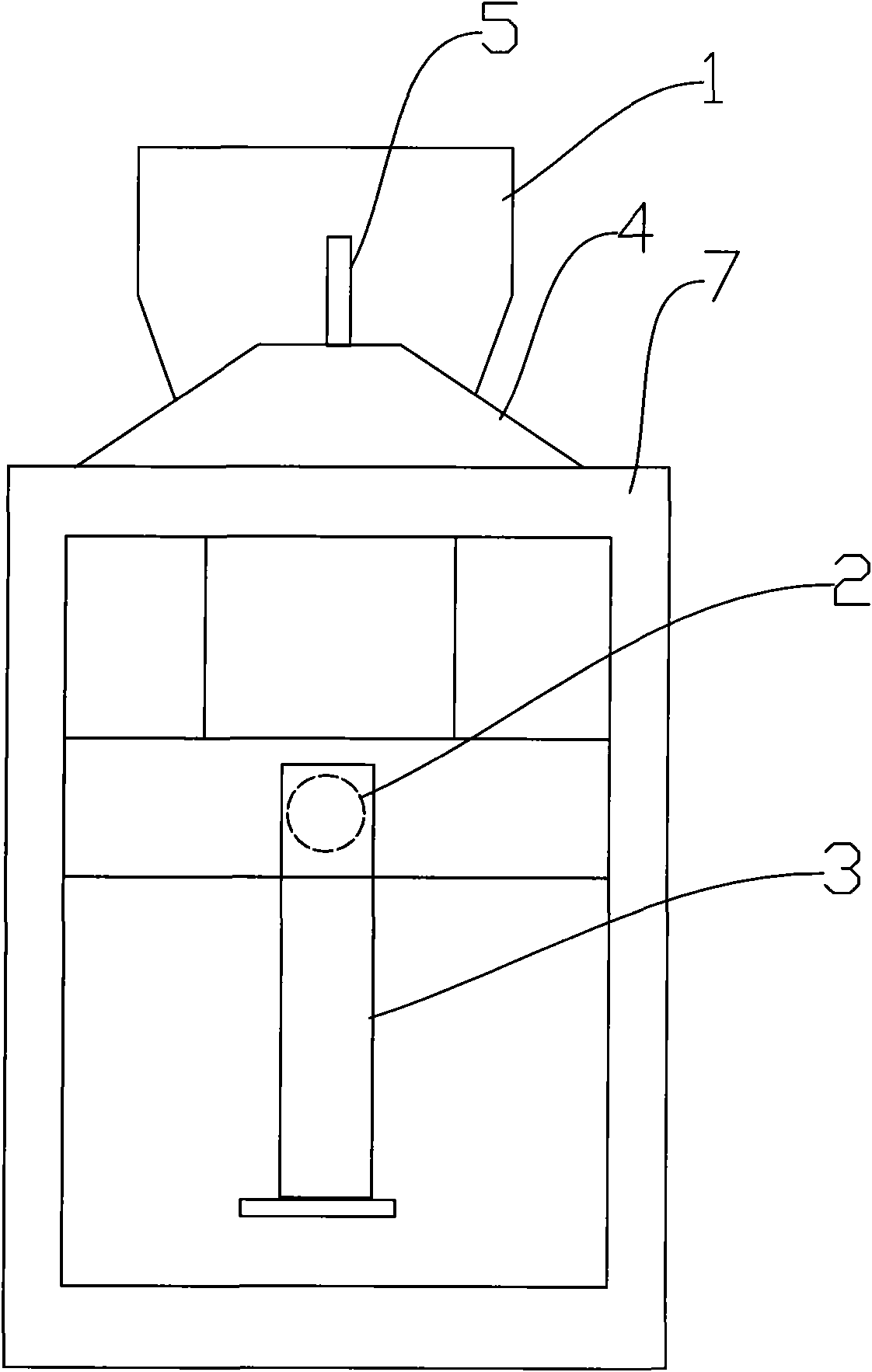

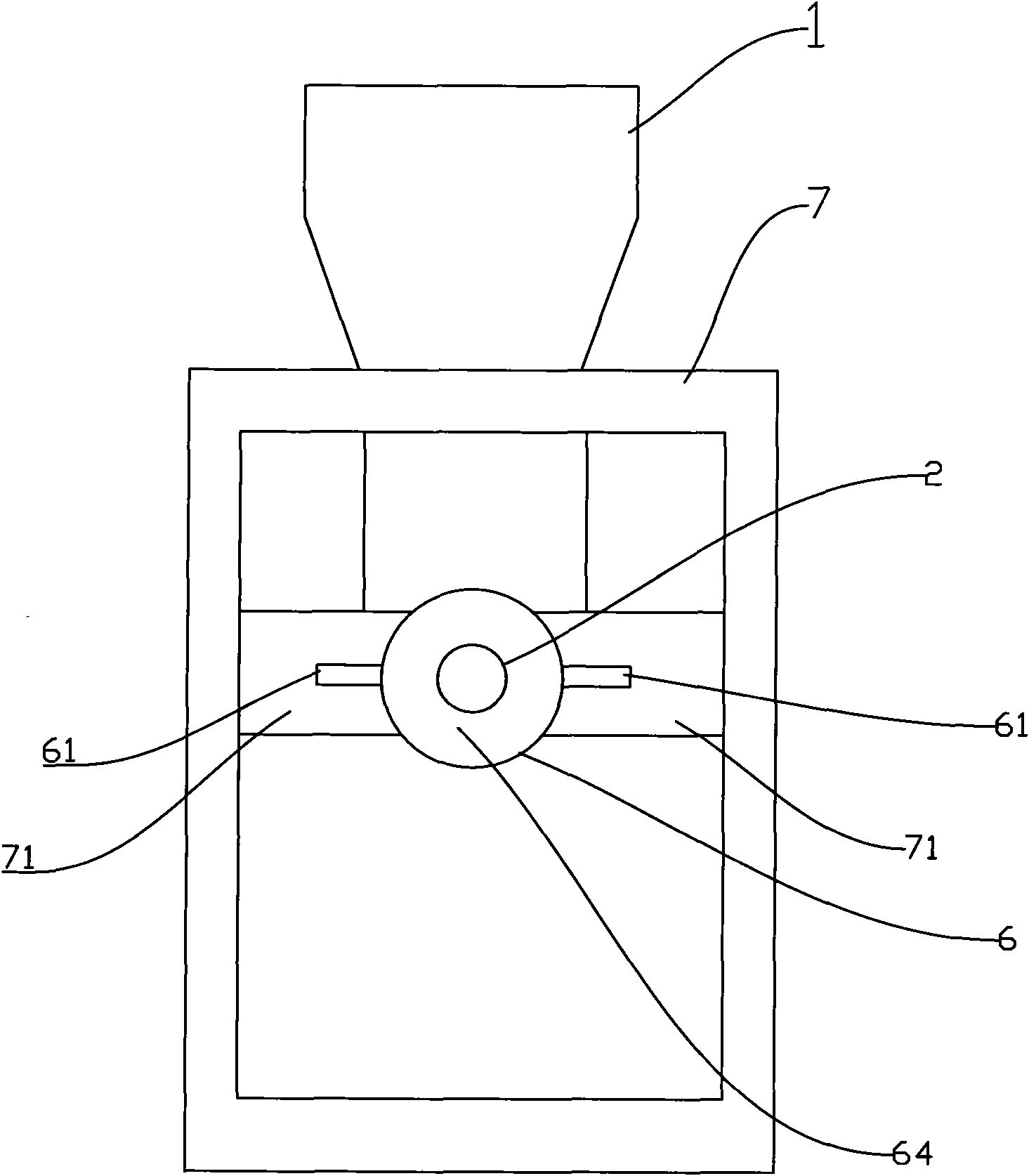

[0034] Such as image 3 Shown is the front view of the dust removal device and powder filling machine; Figure 4 for removing the suction hose image 3 Side view; a powder filling machine with a dust removal device, including a bracket 7, a powder bucket 1 installed on the bracket, and a discharge pipe 2 connected to the powder bucket, and the discharge pipe 2 extends from the side of the support 7 The end of the discharge pipe 2 is provided with a discharge port 21, which is arranged on the side of the support 7 and surrounds the dust collection plate 6 of the discharge pipe 2; the dust suction port 67 arranged on the dust collection plate 6, the suction The dust port 67 communicates with the exhaust fan (not shown in the figure) through the dust suction pipe 61 . The discharge opening 21 has a discharge opening near end 22 and an opening far end 23 . Both ends of the fixing plate 71 are respectively fixed on the bracket 7 , and the dust collecting plate 6 is fixed on the ...

Embodiment 2

[0045] Such as Figure 9 As shown, it differs from Implementation 1 in that the dust collection plate 6 surrounds the discharge pipe 2 and is formed as a cylinder with openings at both ends. The cylindrical dust collection plate 6 has a cavity 63, and the dust suction port (in the figure) (not shown) is located on the cylinder wall of the dust collecting plate 6 and communicates with the cavity. There are two dust suction pipes 61, which communicate with the cavity 63 through the dust suction port respectively, and the discharge pipe 2 passes through the cavity 63.

[0046] In this embodiment, the dust collection plate 6 is arranged around the discharge pipe 2 along the circumferential direction of the discharge pipe 2 , and the dust collection plate 6 is closed with the discharge pipe 2 as the axis along the circumferential direction.

[0047] The dust collection plate 6 is arranged around the discharge pipe 2 to form a cylindrical shape. When the exhaust fan is running, only...

Embodiment 3

[0049] Such as Figure 10 As shown, on the basis of Embodiment 1, the straight cylindrical dust collection plate 6 is changed into a trumpet shape, and the end of the dust collection plate 6 near the discharge port 21 has a larger diameter than the end far away from the discharge port 21, so as to increase the diameter of the opening. The cross-sectional area increases the dust-absorbing space, increases the range of action of the inhaled airflow, and prevents the dust from flying out of the opening of the dust-collecting plate 6 quickly and cannot be inhaled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com