Anti-fake bottle cap

A technology of anti-counterfeit bottle caps and outer caps, which is applied in the device, closure, and packaging of containers to prevent repeated filling. Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

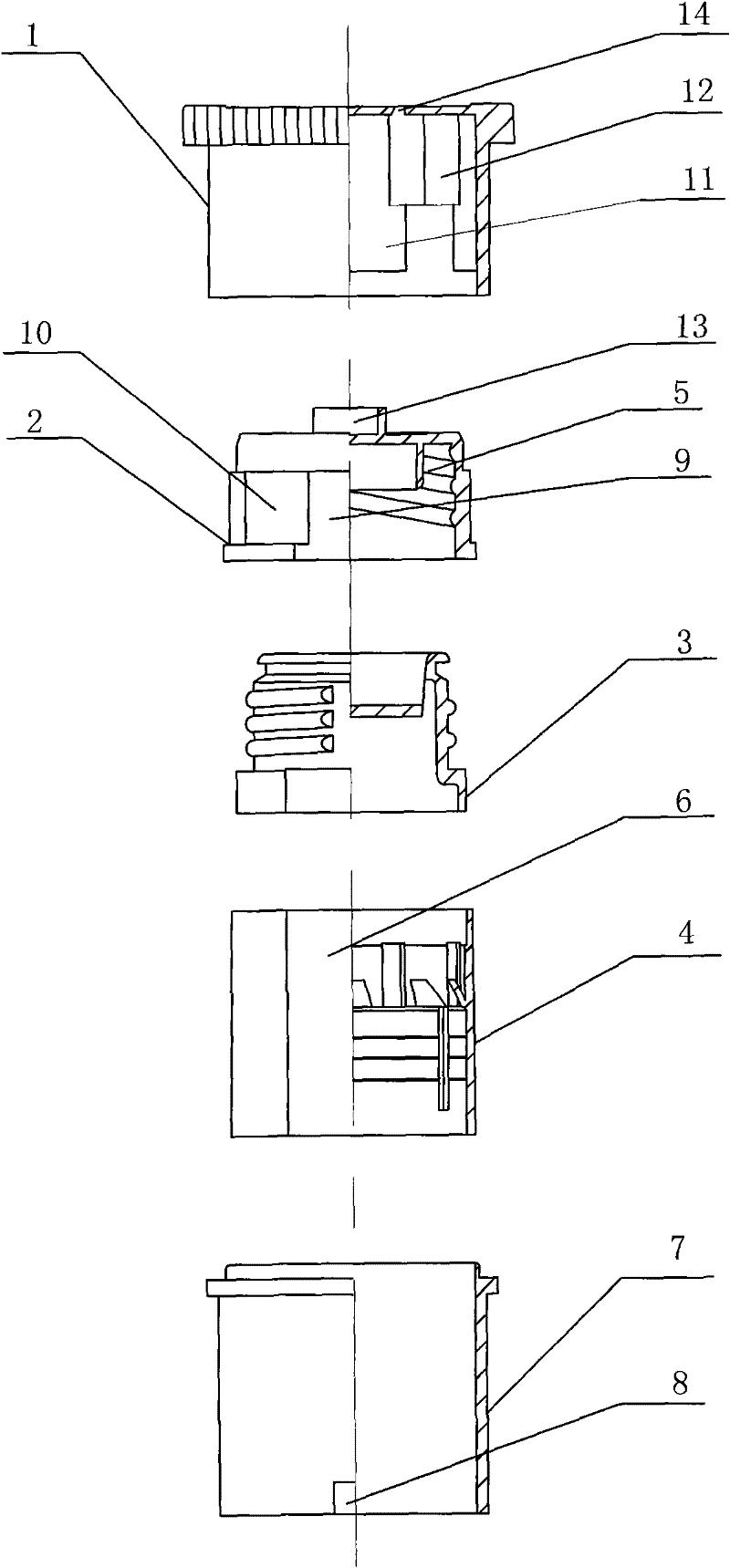

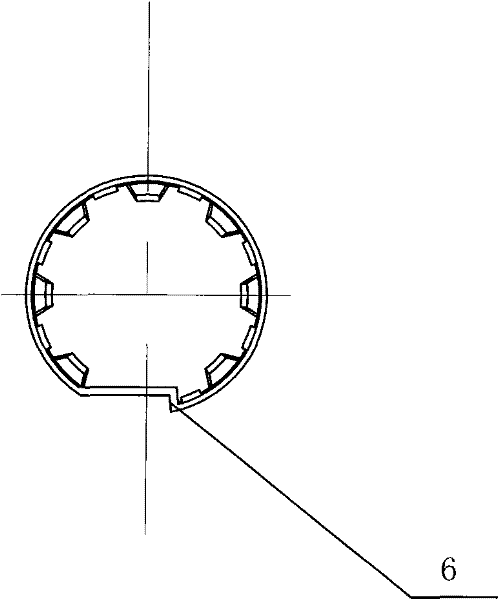

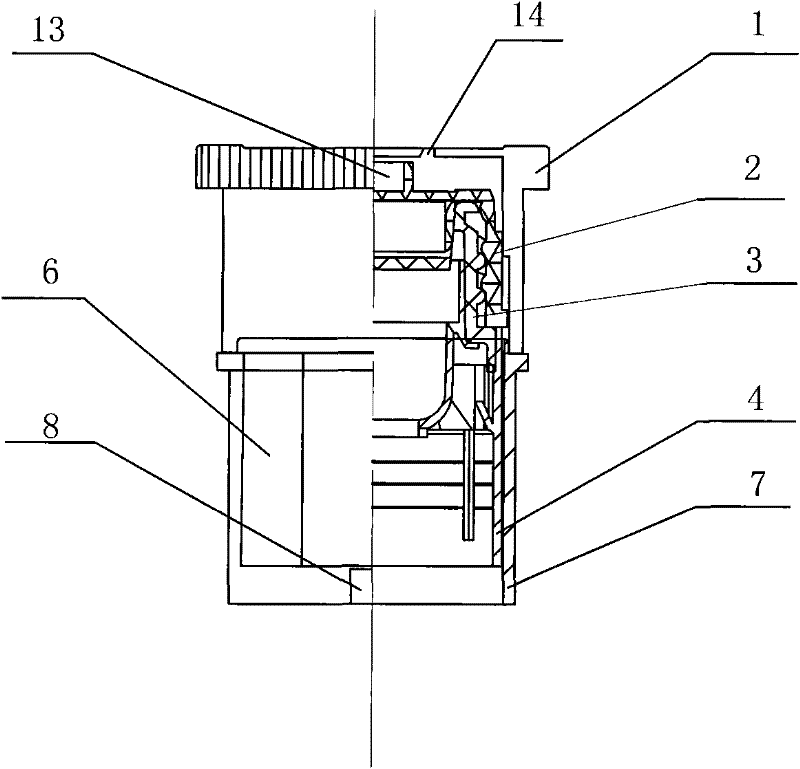

[0010] like figure 1 and figure 2 As shown, the present invention includes an upper outer cover 1, an inner cover 2, a connecting cover 3 and a fixed sleeve 4, the upper outer cover 1 is set outside the inner cover 2, the inner cover 2 is connected with the connecting cover 3 through a thread 5, and the connecting cover 3 is connected with the connecting cover 3. The fixed sleeve 4 is welded, and the fixed sleeve 4 is fixedly installed on the bottleneck. The fixed sleeve 4 is provided with a transparent cover projection guide groove 6 in the longitudinal direction, and the fixed sleeve 4 is covered with a transparent cover 7. The upper outer cover 1 is fixedly connected with the transparent cover 7. The lower end of the cover 7 is provided with a projection 8 that matches the projection guide groove 6 of the transparent cover, and the projection 8 cooperates with the glass projection on the bottle neck. The inner cover 2 is longitudinally provided with a thrust groove 9 and a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap