Cable coil putting device

A pay-off device and cable reel technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of personal injury, damage to cables, waste of manpower and material resources, etc., and achieve high work efficiency and low cost. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

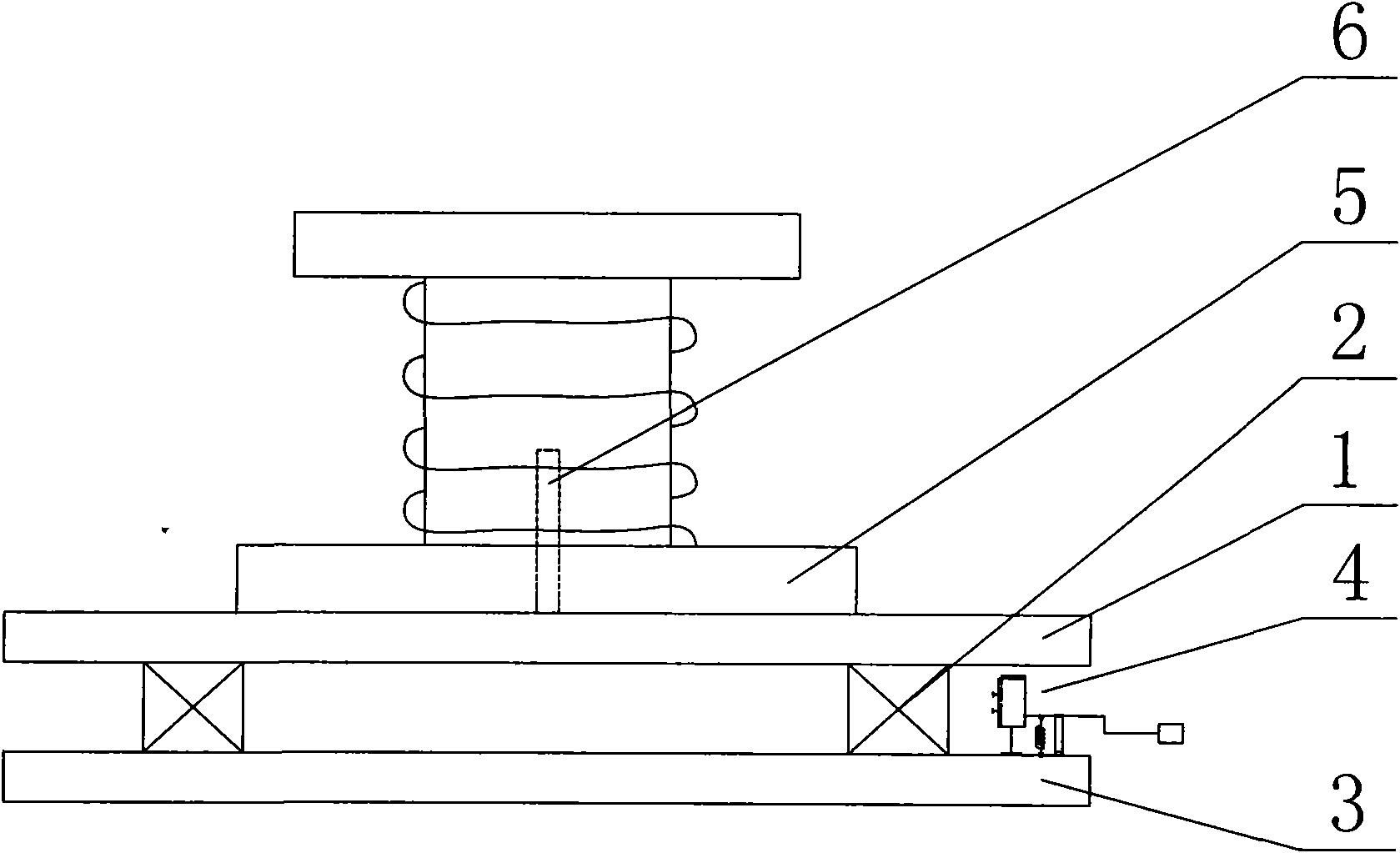

[0013] See figure 1 , The cable reel pay-off device is composed of an upper chassis 1, a lower chassis 3, a rolling bearing 2, and a speed control device 4. A rolling bearing 2 is provided between the upper chassis 1 and the lower chassis 3, and a speed control is provided at the outer edge of the rolling bearing 2. Device 4, the speed control device 4 is located between the upper chassis 1 and the lower chassis 3, this device can artificially control the rotation speed of the cable reel, avoiding the loss caused by the shedding of the cable due to excessive tension. The steel pipe 6 that prevents the cable tray 5 from moving is welded vertically with the upper chassis 1 at the upper center position.

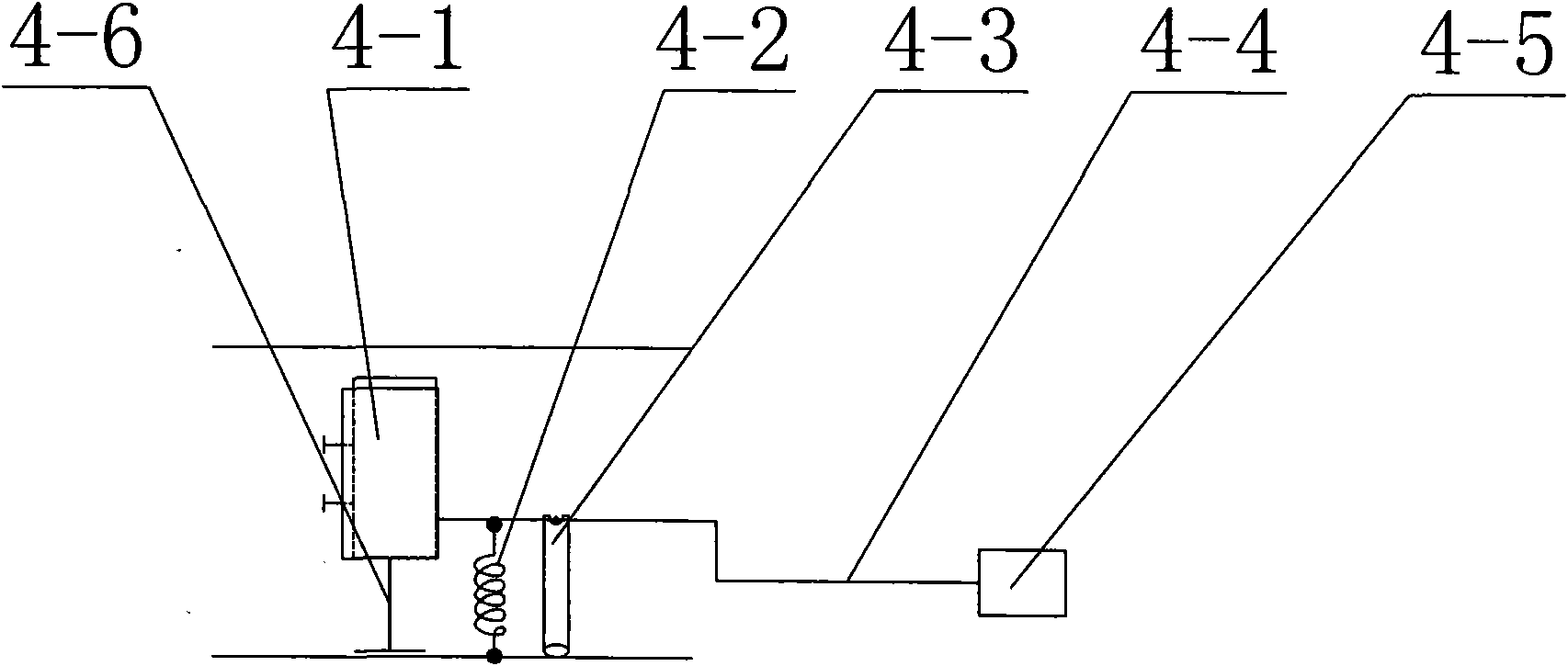

[0014] See figure 2 , speed control device 4 is made up of rubber brake pad 4-1, return spring 4-2, pole 4-3, control rod 4-4, pedal 4-5, support rod 4-6, rubber brake pad 4- 1 Connect the pedal 4-5 through the control rod 4-4, the lower part of the control rod 4-4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com