Rotary advancing and cutting device for tunnel

A cutting device and rotary cutting technology, used in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of dangerous over-under-excavation, inability to construct hard rock layers, slow construction progress, etc., to ensure comprehensiveness and flexibility. performance, enhanced rock cutting efficiency, and controllable rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

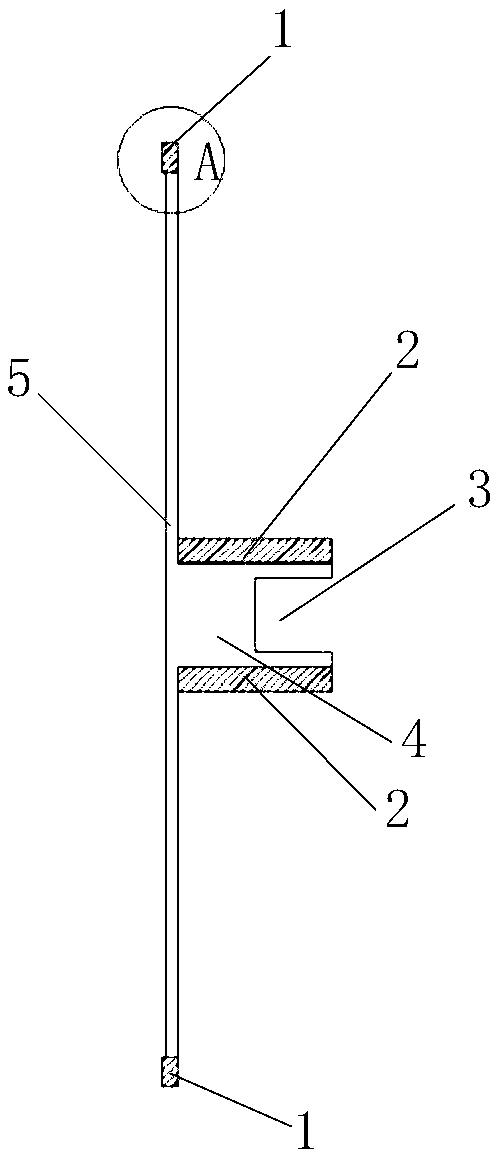

[0029] Such as Figure 1-10 As shown, a rotary propulsion cutting device for tunnels includes a rotary cutting head and a propulsion device; the rotary cutting head includes a cutting device and a rotating device; the center of one side of the cutting device is provided with a A power shaft installation hole; a rotating mechanism for driving the overall rotation of the cutting device is provided on one side of the cutting device off-center.

[0030] Such as Figure 1-10 As shown, a rotary propulsion cutting device for tunnels is used for cutting rocks in tunnels. Through the joint action of the propulsion device of the present invention and the rotary cutting head, the longitudinal and transverse cutting of tunnel rocks is realized, and the rotary cutting The overall rotation of the device in the plane enhances the comprehensiveness and flexibility of the present invention for cutting rocks, and effectively prevents the occurrence of under-excavation of rocks; It is more con...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 lies in the technical characteristics of the cutting mechanism, and the rest are the same as embodiment 1.

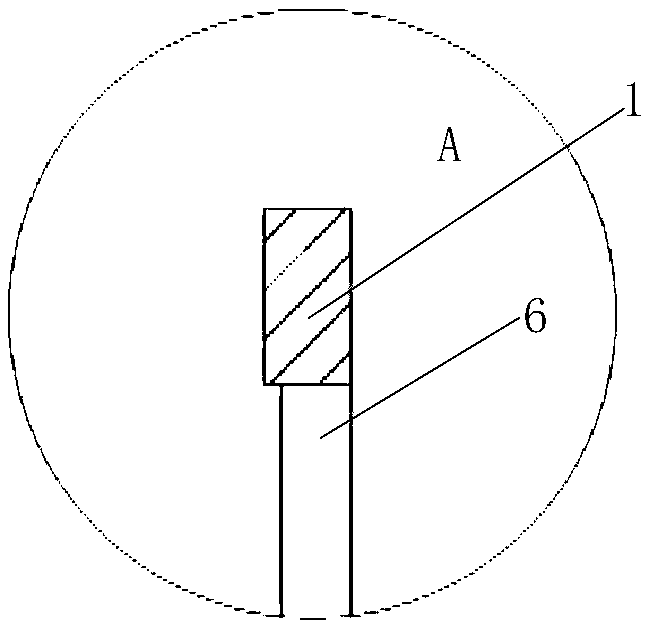

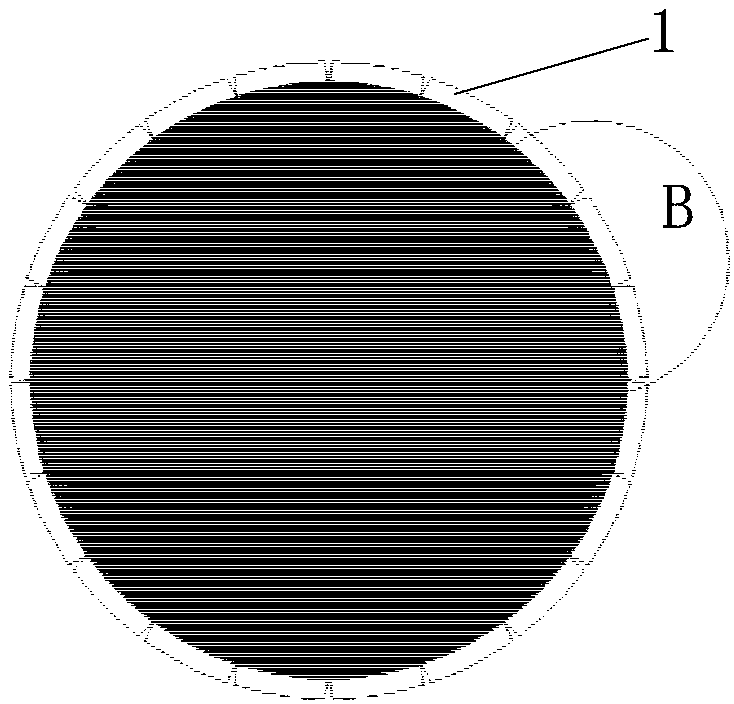

[0046] Such as Figure 1-5 As shown, a cutting device for a tunnel includes a cutting head, a fixing device, a turret, a rotating mechanism and a rotating motor; the cutting mechanism includes a cutting carrier; the cutting carrier includes a rotating carrier part and a fixed part; the rotating The carrier part is a circular structure; the edge of the rotating carrier part is evenly provided with several rotating carrier connecting parts 6; each rotating carrier connecting part is provided with a first cutting part, and the center of the fixed part and the rotating carrier part One side is connected; the fixed part is a circular structure; several second cutting parts are uniformly arranged on the outside of the fixed part; first cutting openings are arranged between adjacent first cutting parts, and adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com