Rice polishing system capable of automatically controlling rice polishing degree

A rice polishing and degree technology, applied in the field of rice polishing system, can solve the problems of large volume, complex structure, uncontrollable degree of rice polishing, etc., and achieve the effect of controllable rotation speed and uniform turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

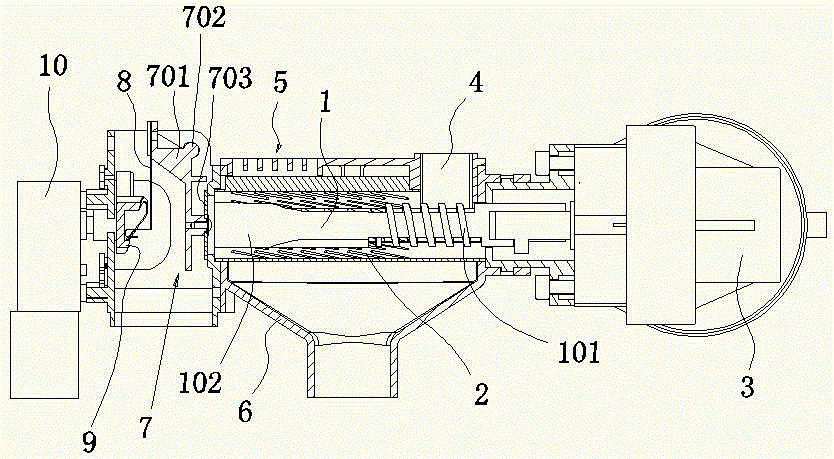

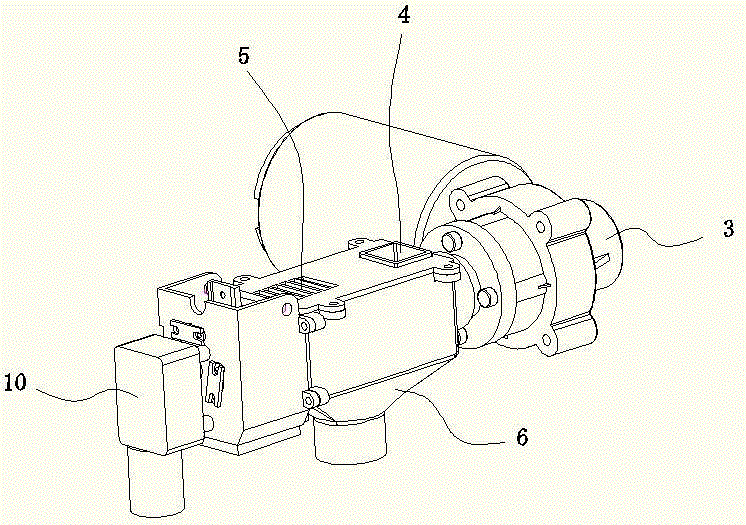

[0022] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 5 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

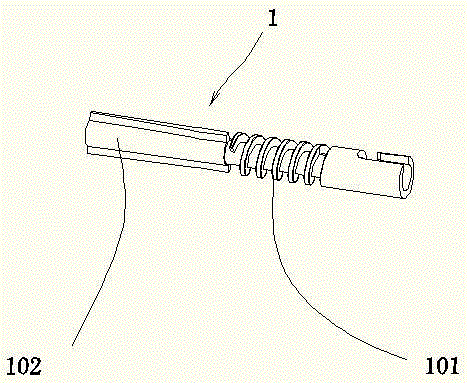

[0023] The present invention is a rice polishing system with automatic control of the degree of rice polishing, which includes a rice polishing device and an electric control device. The rice polishing device includes a rice polishing room, a throwing bar 1 arranged in the rice polishing room, and a screen set on the periphery of the throwing bar 1 2. The throwing rod 1 is driven by the rice polishing motor 3, and the screen 2 is arranged horizontally. The throwing rod 1 at the rice inlet end of the screen 2 is a screw structure 101, and also includes an outlet stopper 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com