Compound rotary polishing method of centrifugal pump impeller

A centrifugal pump impeller and composite technology, applied in the direction of grinding/polishing equipment, surface polishing machine tools, manufacturing tools, etc., can solve the problems of complex device structure, low polishing efficiency, large volume, etc., to achieve increased particle concentration, Good grinding effect, reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

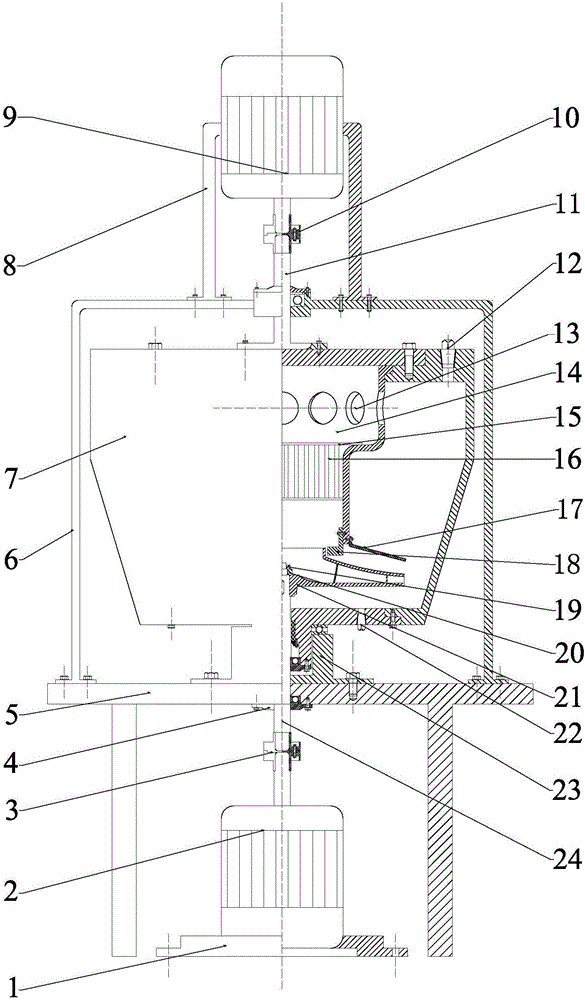

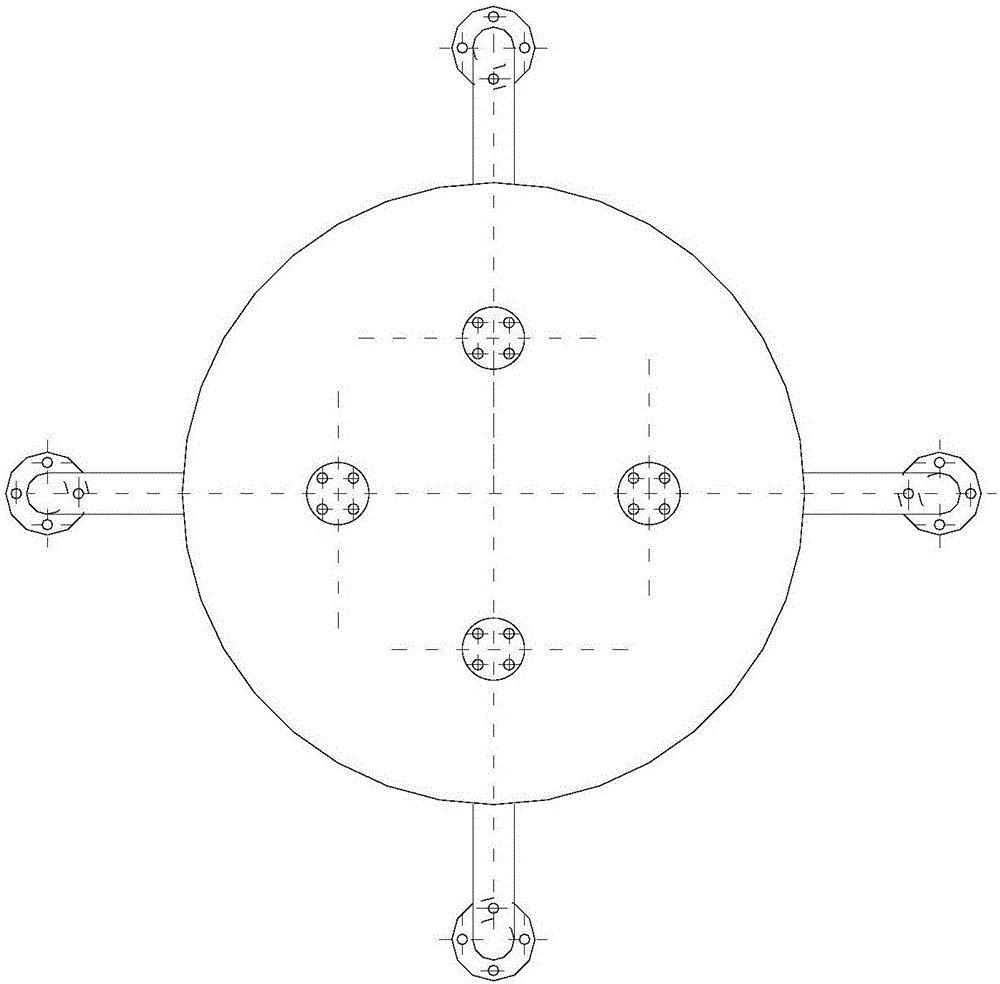

[0046] refer to figure 1 and figure 2, a centrifugal pump impeller compound rotary polishing method, the polishing device supporting the polishing method includes a base 1, a frame 6, a cylinder 7, an impeller 21, an impeller bushing 23, a bottom drive shaft 25, a top drive shaft 11, a stable The flow device 16, the baffle 17, the mouth ring 18, the water storage tank 14, the orifice plate 15, the bottom drive device 2 and the top drive device 9, the bottom drive device 2 is installed on the base 1, and the bottom drive device 2 The output shaft is connected with the bottom transmission shaft 25, the cylinder 7 is located on the workbench 5, the impeller 21 is installed in the cylinder 7, the transmission shaft 25 passes through the workbench and extends into the cylinder 7, so The upper end of the transmission shaft 25 is fixedly connected with the impeller 21 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com