Drum type washing machine

A drum-type washing machine, washing machine technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of increasing vibration, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

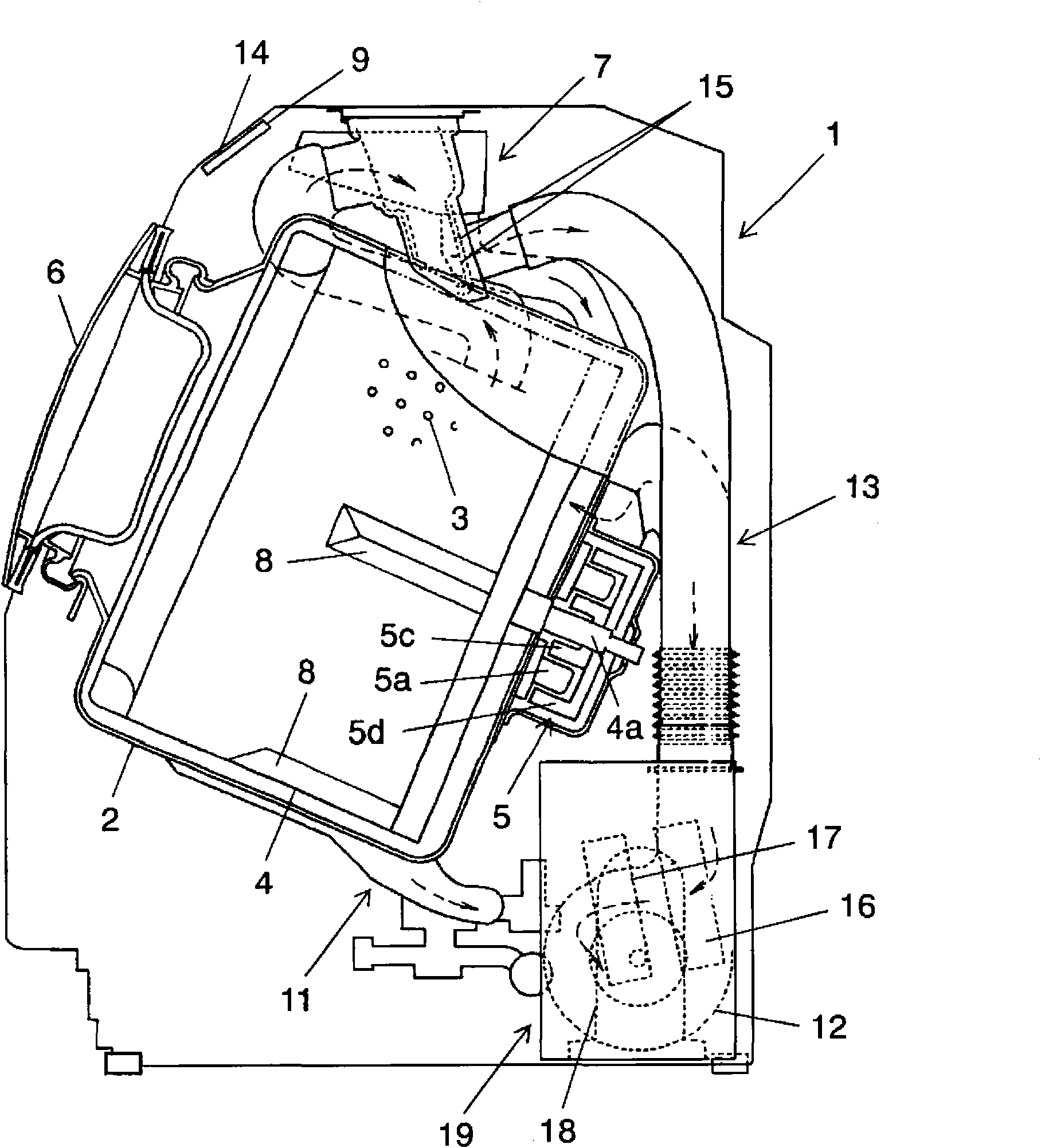

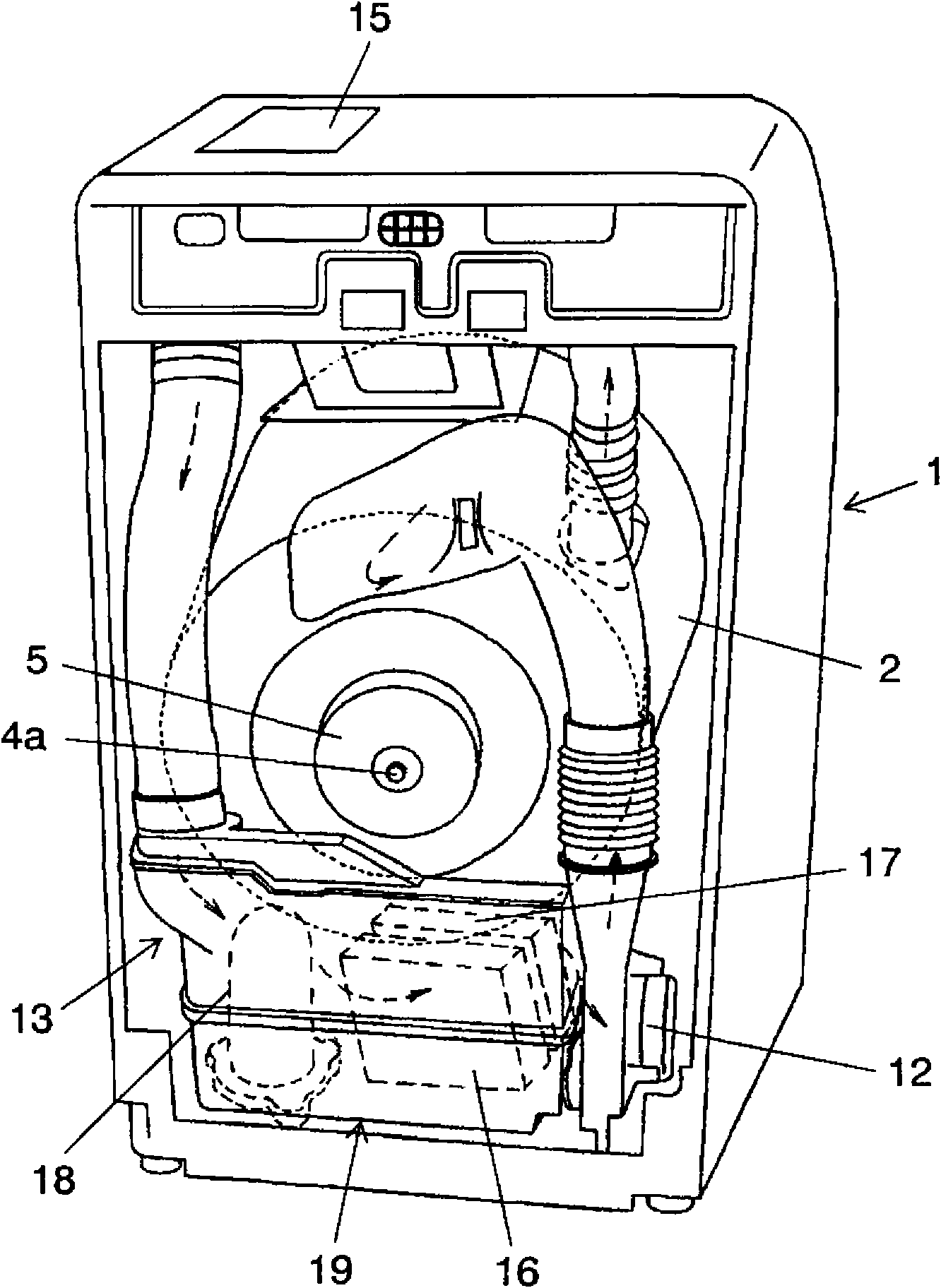

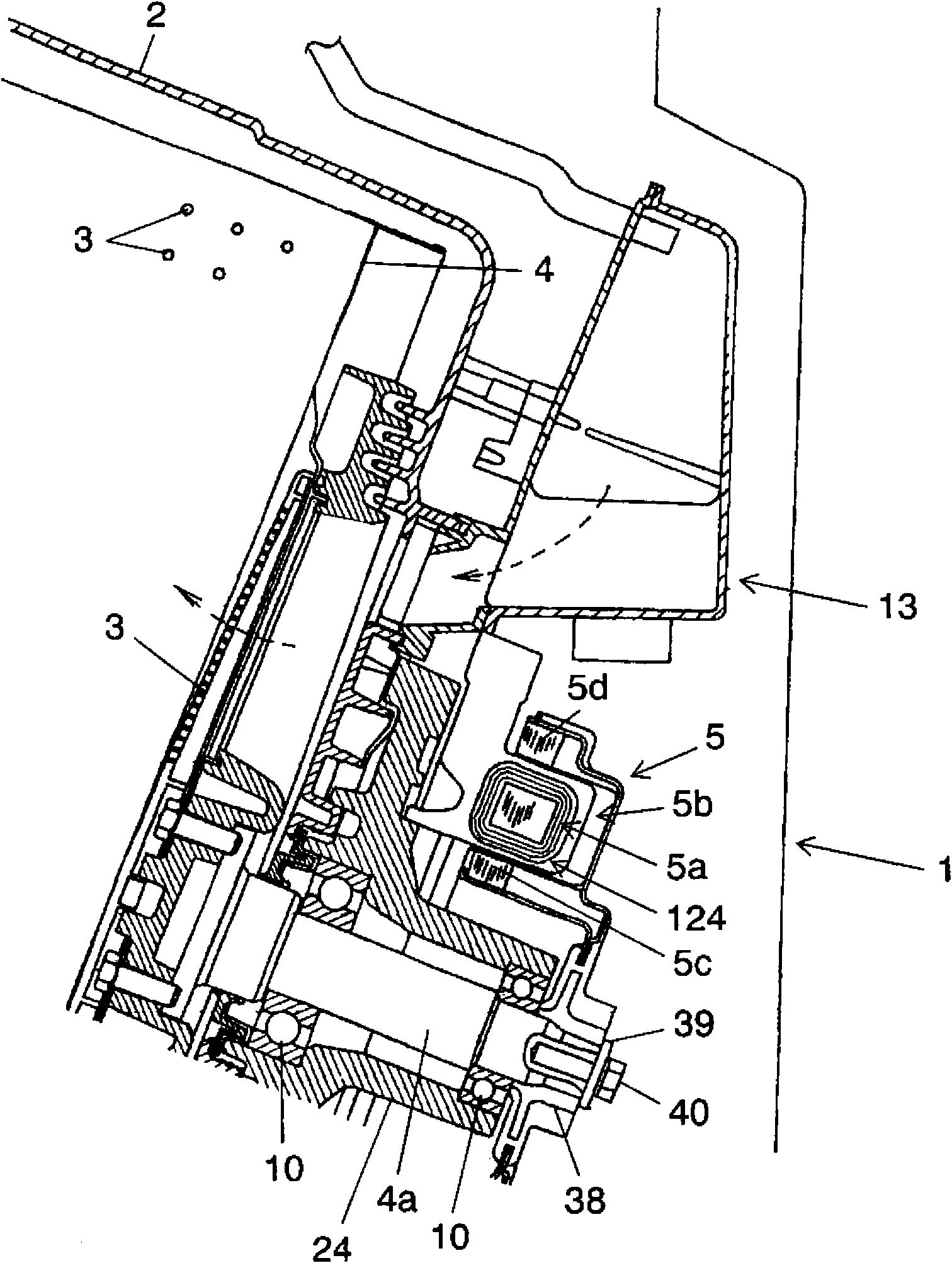

[0043] figure 1 It is a cross-sectional view showing the structure of main parts of the front-loading washing machine according to the embodiment of the present invention, figure 2 It is a rear view when looking at the inside of this front-loading washing machine, image 3 It is a cross-sectional view showing approximately half of the motor mounting portion of the front-loading-type washing machine.

[0044] The drum type washing machine according to the embodiment of the present invention has the basic structure already described, as figure 1 As shown, in the water tank 2 elastically supported in the main body 1 of the washing machine by a suspension structure, a rotary drum 4 having a plurality of holes 3 is arranged. The rotary drum 4 is driven to rotate by the motor 5, and the laundry can be rotated through the front opening of the water tank 2 and the front opening of the rotary drum 4 by opening the door 6 freely openable and closable provided on the front side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com