Medicinal powder filling device of fully-automatic capsule filling machine

The technology of a filling device and a filling machine is applied in the directions of capsule delivery, drug delivery, pharmaceutical formulation, etc., which can solve the problems of large thickness of the spacer block, influence on the fluidity of medicinal powder, influence on the accuracy of capsule filling, etc., so as to ensure the accuracy of filling and improve the The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

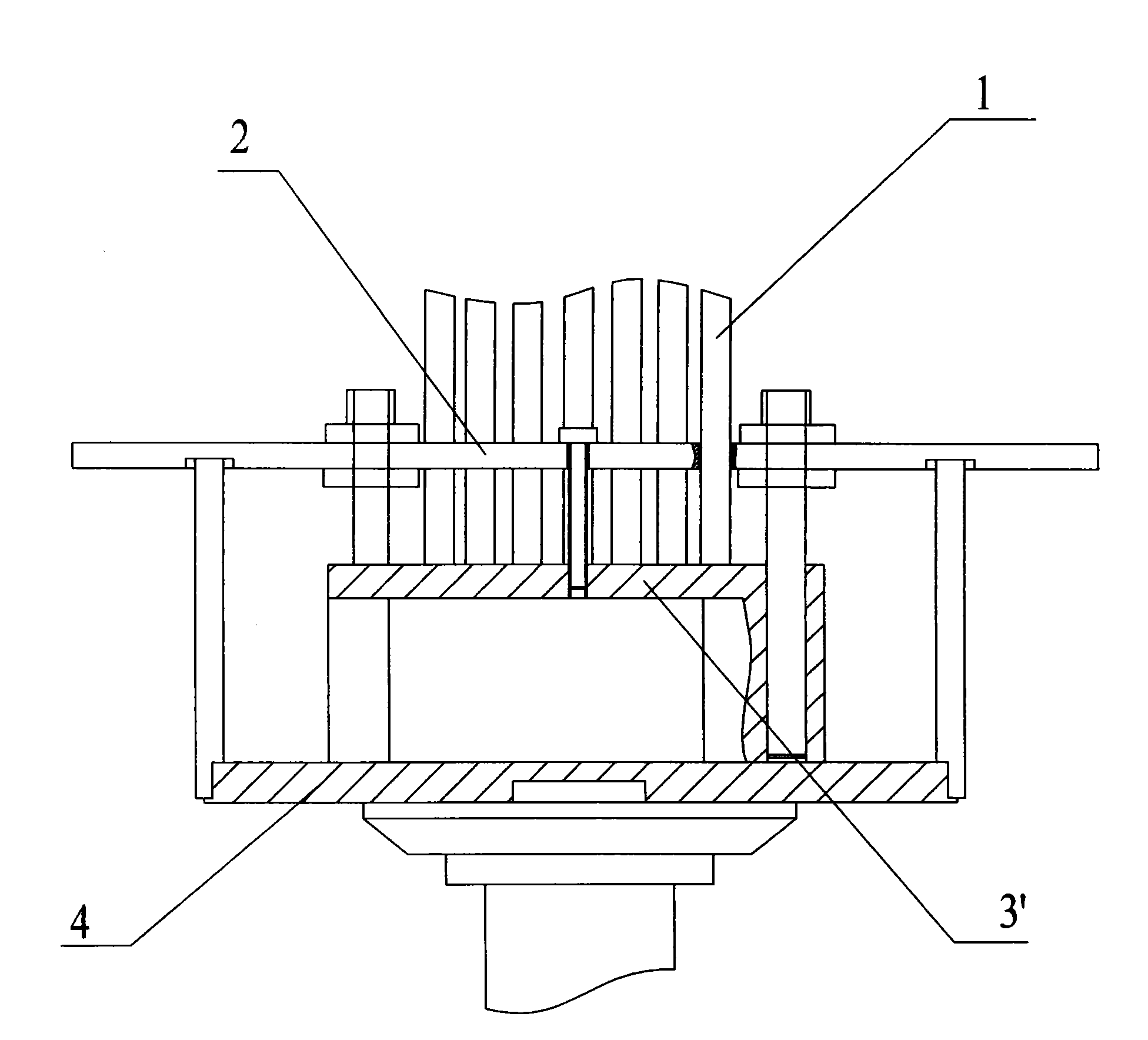

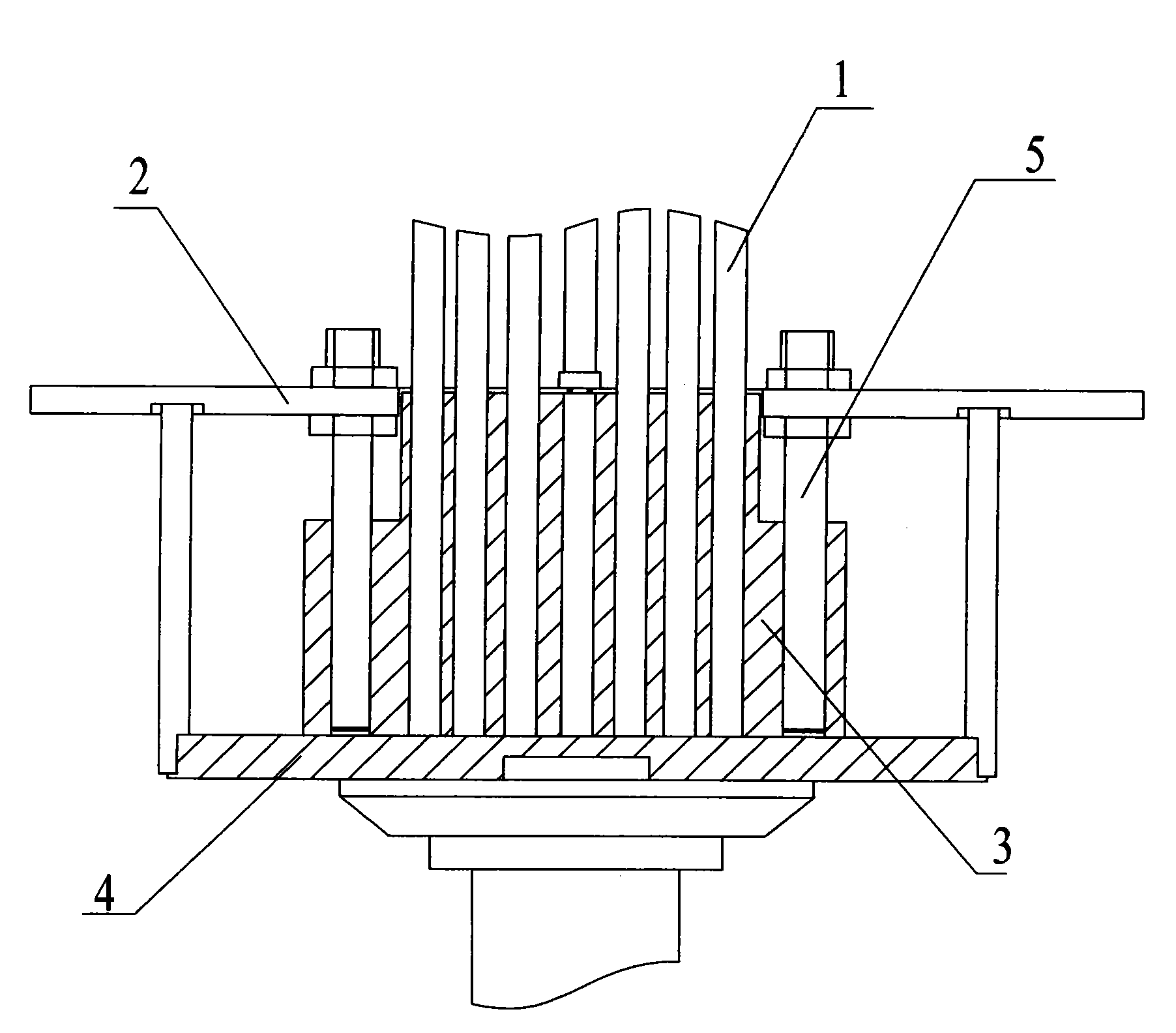

[0009] see figure 2 , the powder filling device of the filling machine of the present invention mainly includes a filling rod 1, a cover plate 2, a spacer block 3 and a metering disc 4, wherein the upper surface of the spacer block 3 is in close contact with the cover plate 2, and there is no gap between the two . During the working process, the filling rod 1 passes through the cover plate 2 and the isolation block 3, pushes the medicine powder to the bottom of the metering disc 4 and then pulls it out. During operation, the metering disc 4 rotates, and the bottom of the spacer 3 scrapes the powder on the surface of the metering disc so that the medicine column in the metering disc remains at the same height.

[0010] The spacer block 3 is connected to the cover plate 2 through two guide rods 5 , and the gap between the spacer block 3 and the metering disc 4 can be adjusted through the guide rods 2 . Since there is no gap between the upper surface of the isolation block and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com