Dual-metal-band saw-blade strengthening tooth for enhancing strength of welding line

A technology of double metal strips and strengthened welds, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tools, etc., to achieve the effects of high-efficiency and high-speed sawing, prolonging the service life, and strengthening the strength of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

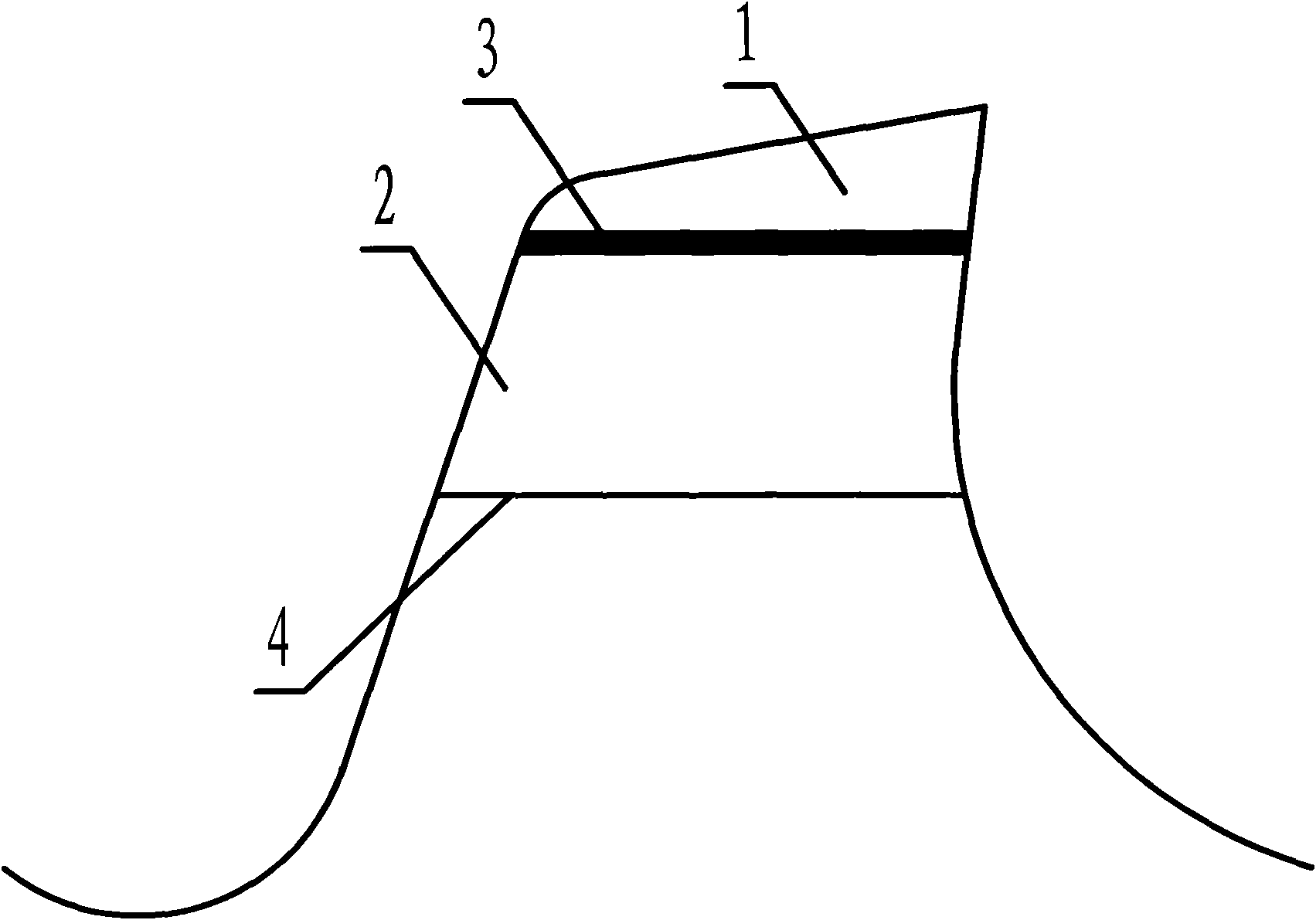

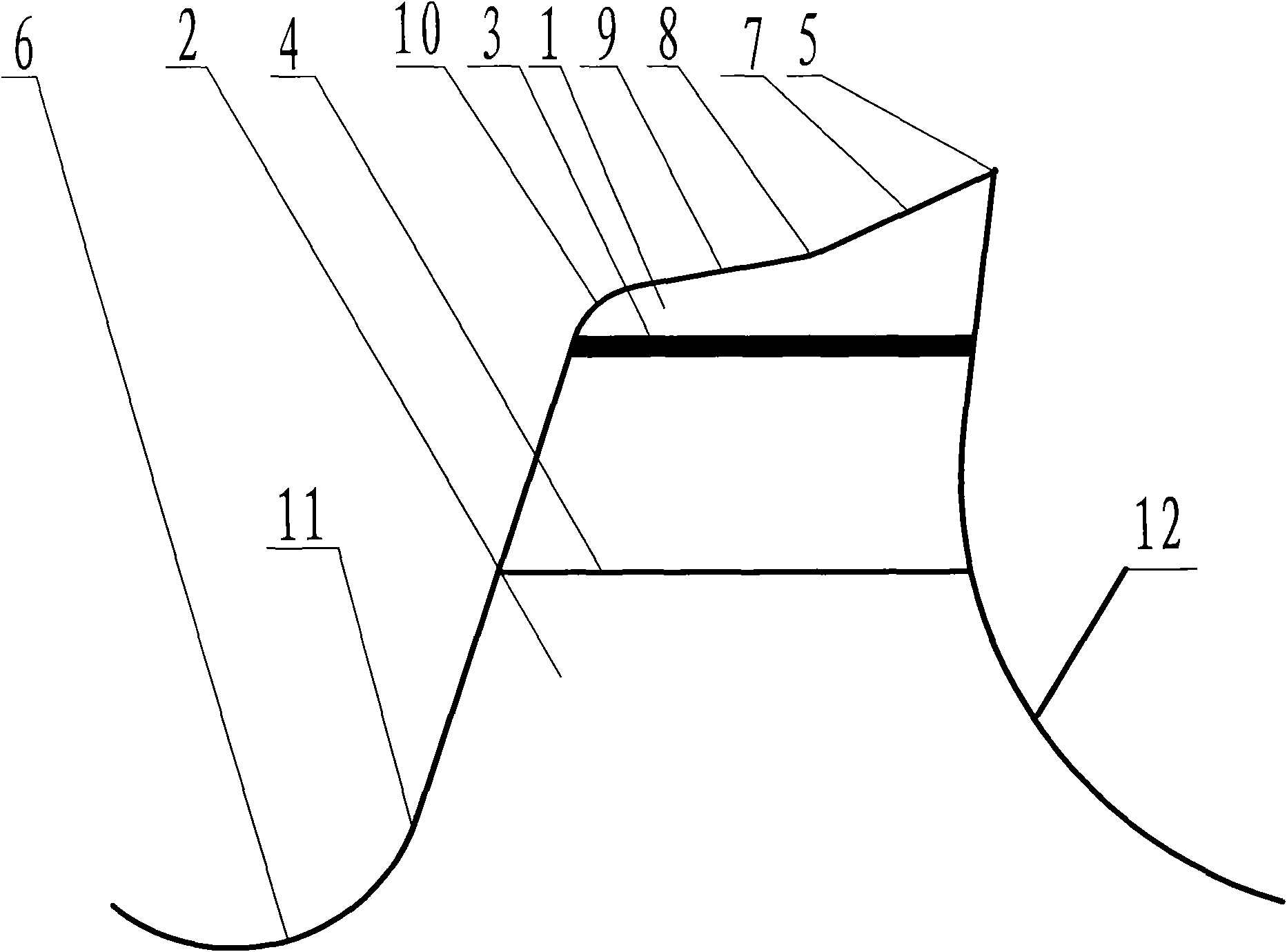

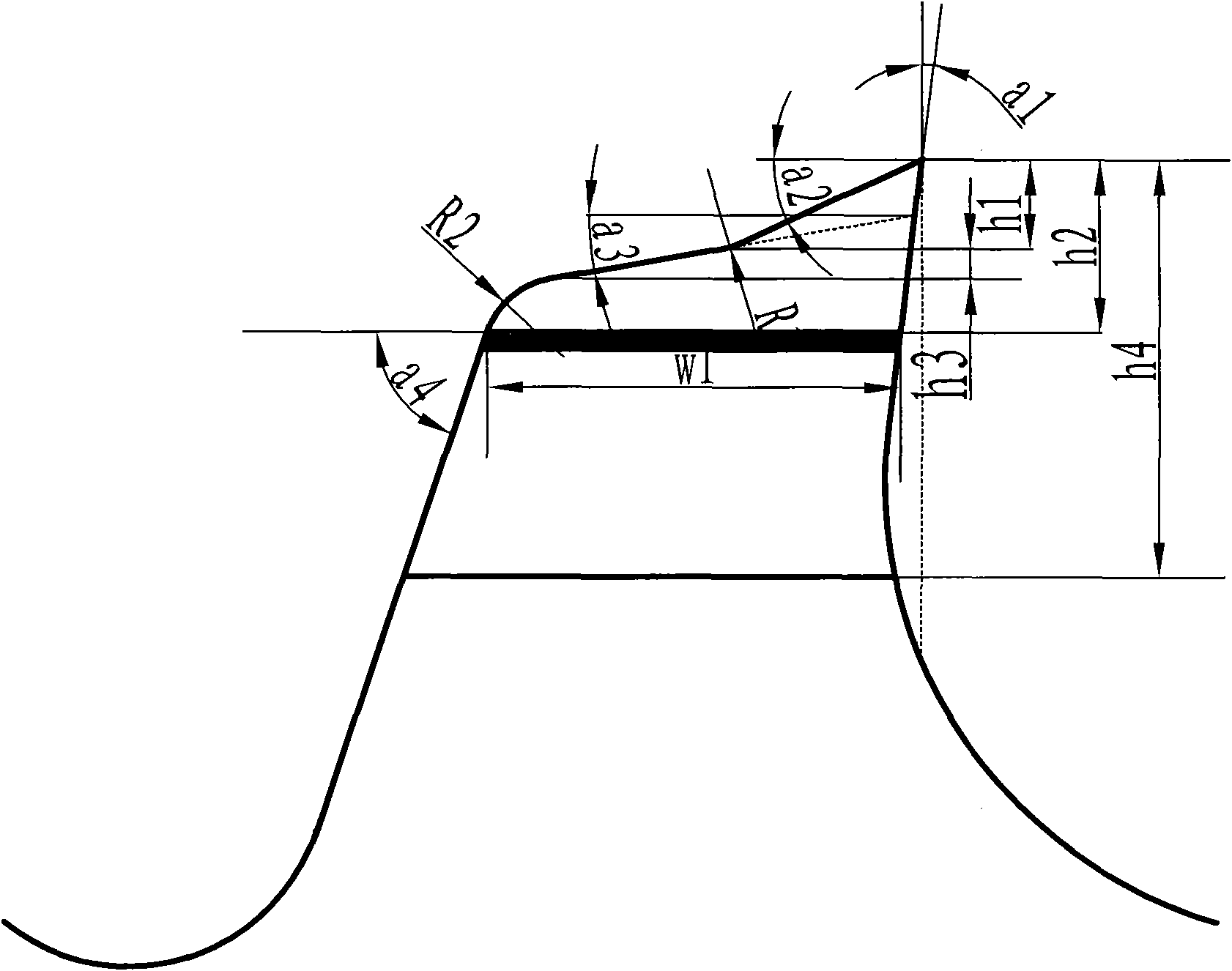

[0041] Such as Figure 2 to Figure 5 As shown, the double-metal band saw blade reinforcing tooth of the present invention that can strengthen the strength of the weld is composed of a back material part 2 and a tooth material part 1 welded on the back material part, and the tooth edge has a third rear corner edge 11, The second rear corner edge 9, the front edge 12, and there is a transition fillet 10 between the third rear corner edge 11 and the second rear corner edge 9, and the third rear corner edge 11 is terminated with the tooth groove line 6; A first rear corner edge 7 is provided between the top of the front edge 12 and the second rear corner edge 9 so that the tooth shape becomes a three rear corner shape, and there is a transition circle between the second rear corner edge 9 and the first rear corner edge 7 Angle 8, and the first relief angle a2 is greater than the second relief angle a3, the second relief angle a3 is smaller than the third relief angle a4, and there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com