Reinforcing bar binder

A technology of strapping machine and steel bar, applied in construction, building structure, construction material processing and other directions, can solve problems such as poor torsion, increased friction, reduced lubrication function, etc. The effect of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Typical embodiments of the present invention will be described with reference to the drawings.

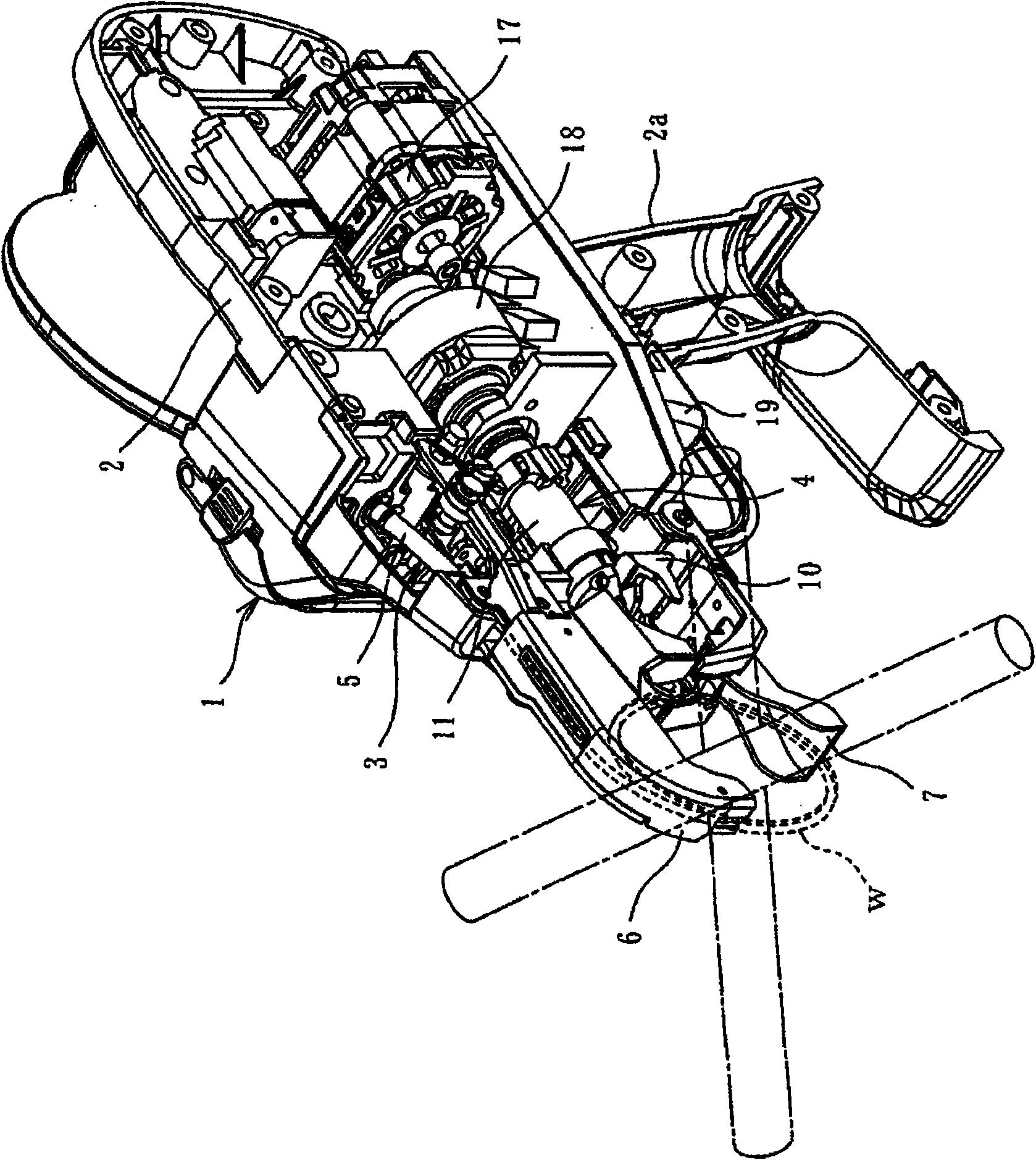

[0062] figure 1 It is a perspective view showing the internal state of the steel bar binding machine. The steel bar binding machine 1 is equipped with a steel wire feeding device 3 and a steel wire binding device 4 in a casing 2, and a steel wire is rotatably pivotally mounted on the rear side of the casing 2. reel (not shown).

[0063] On the steel wire feeding device 3, the steel wire w wound on the steel wire reel is sent from the guide pipe 5 to the steel wire guide 6 through a feed roller not shown in the figure, where it is coiled, and between the lower guide 7 A device that is wound around a steel bar (not shown) in an annular shape. The steel wire binding device 5 is a device that grasps a part of the annular steel wire w and twists and binds it. cut off.

[0064] The steel wire feeding device 3 and the steel wire binding device 4 are sequentially controlled by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com