Multi-port compression connector with single tap wire access port

A technology for compressing connectors and branching wires, which is applied in the direction of connection, connection, conductive connection and other directions where permanent deformation plays a role, and can solve problems such as extrusion tool breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

detailed description

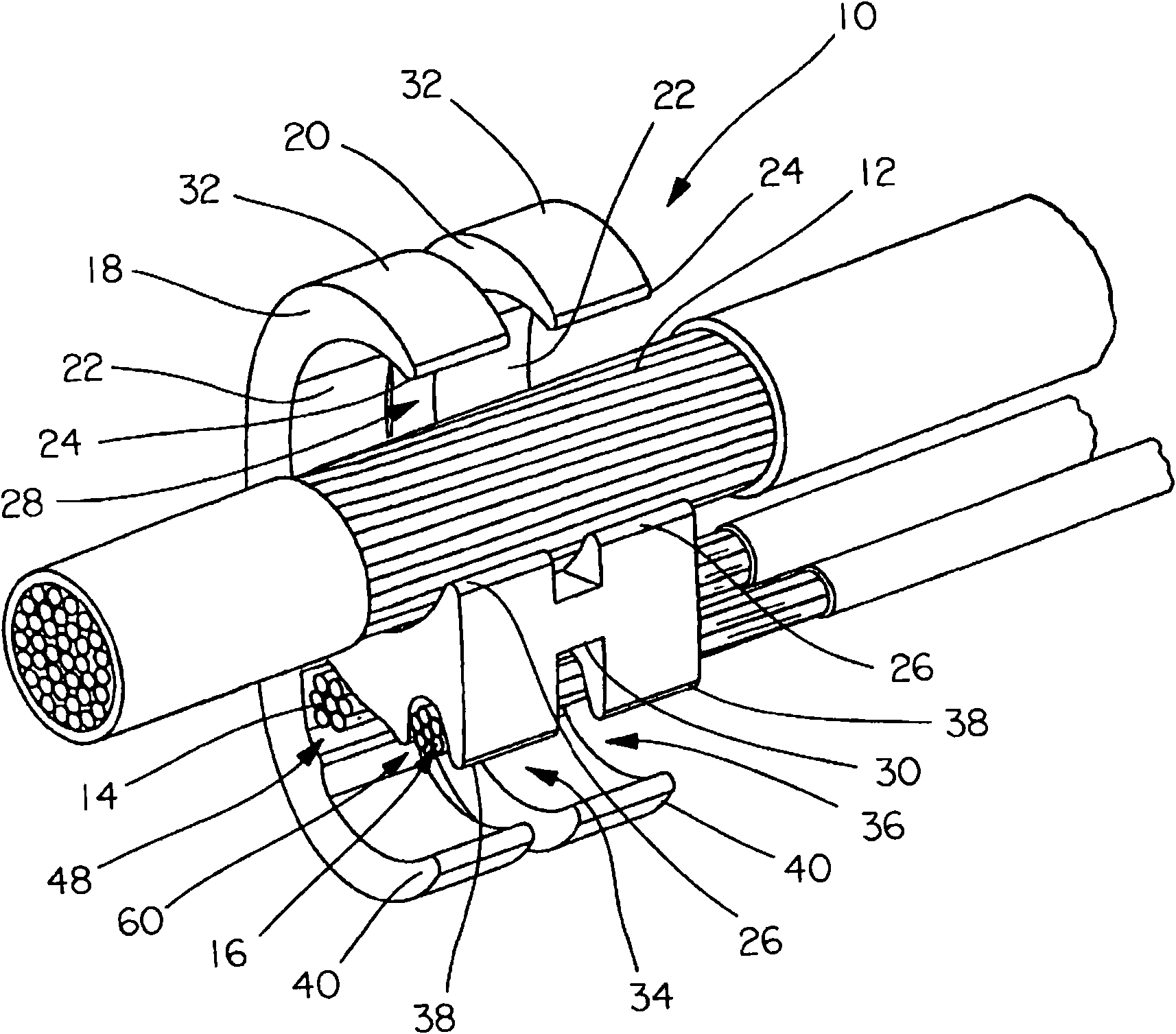

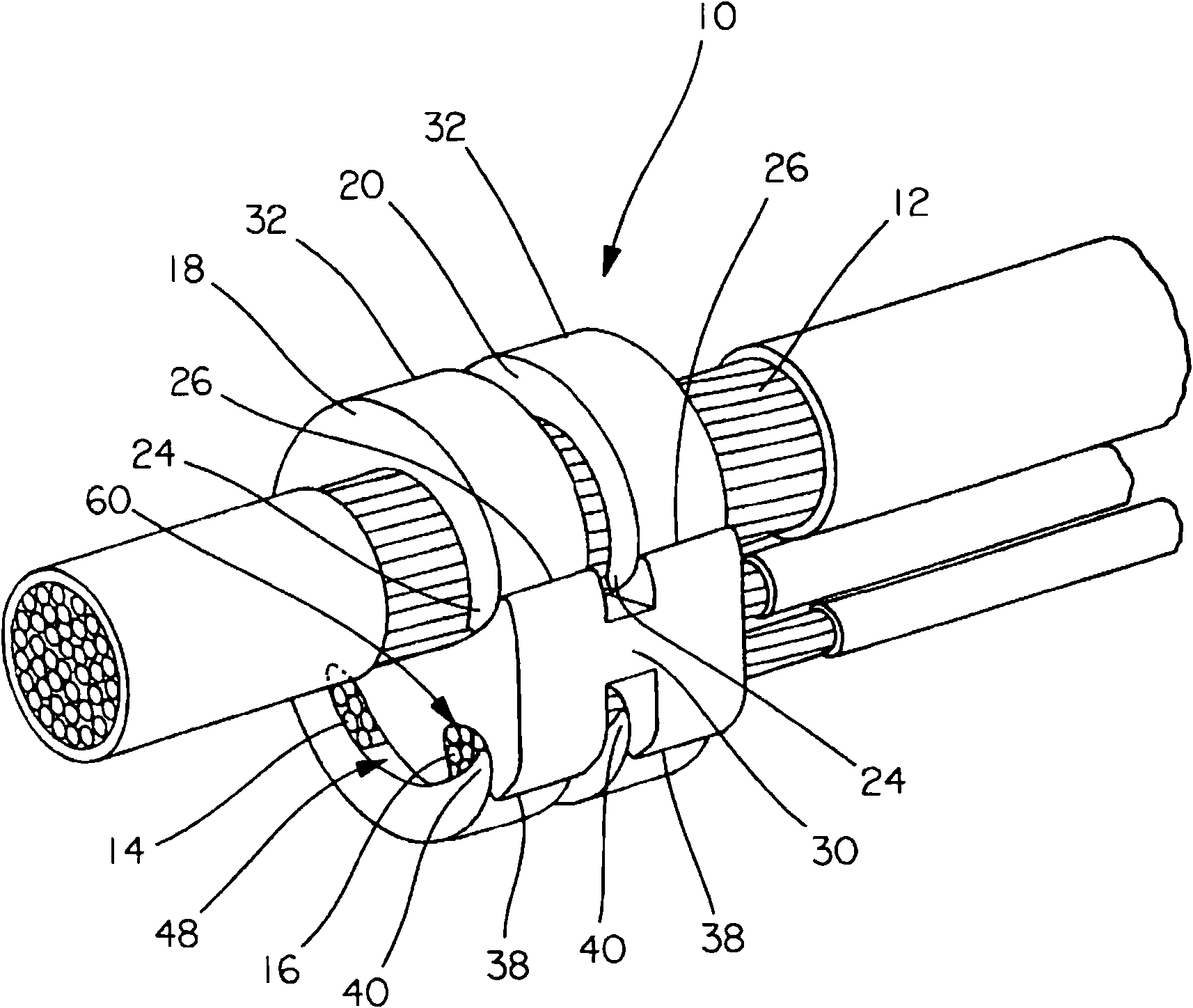

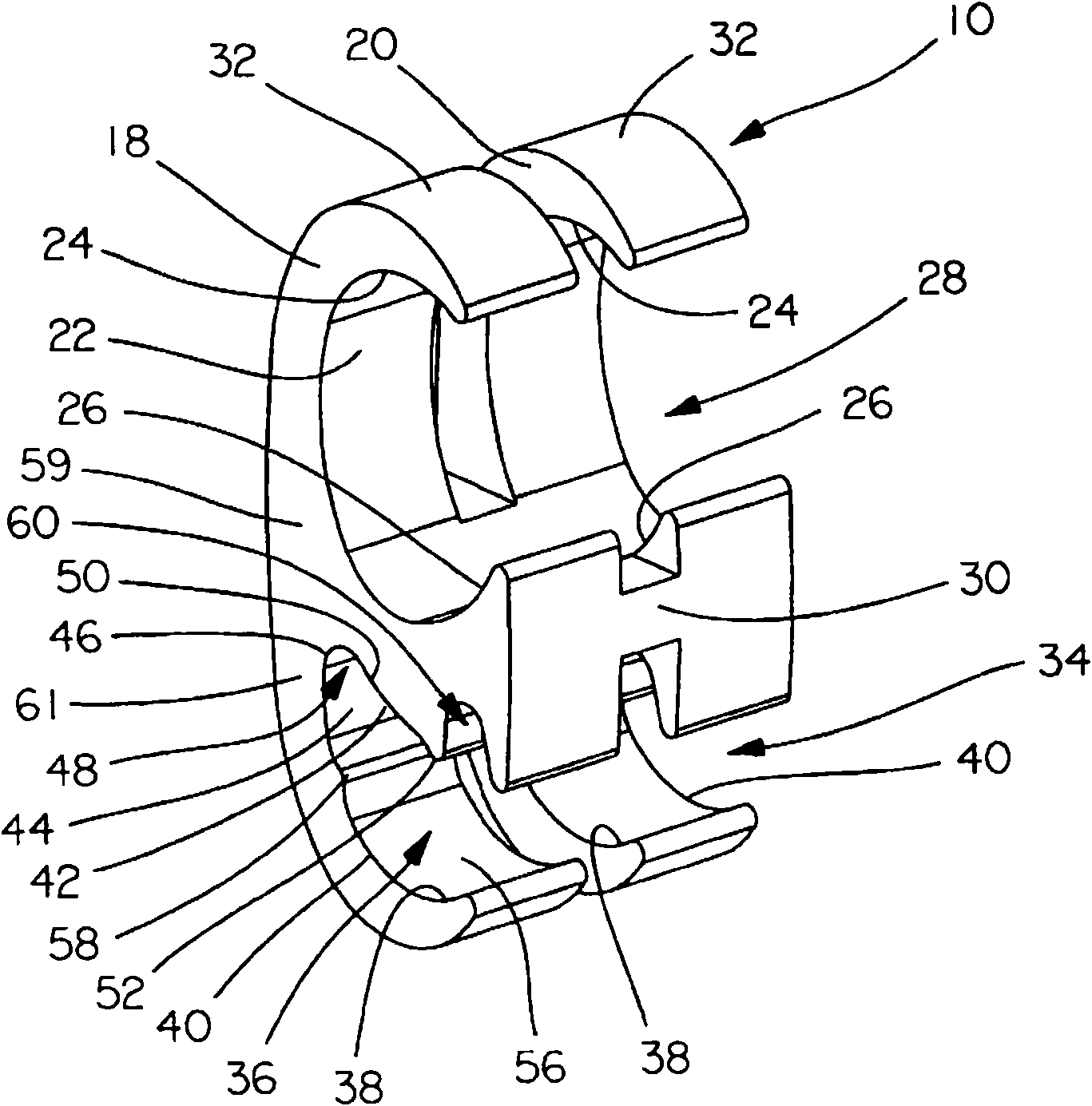

[0024] Embodiments described herein relate to a compression connector body having a single tap wire opening external to the connector body that communicates with a common tap wire port that is received in a plurality of differently sized tap wire receptacles Multiple breakout lines within the size range. Each tap wire nest communicates with a single opening in the common tap wire port. Figure 1-11 A first embodiment of a compression connector is described, Figure 12-14 A second embodiment of a compression connector is described.

[0025] figure 1 Compression connector 10 is shown prior to being crimped and secured around trunk wire 12 and two tap wires 14 and 16 . As shown, the compression connector 10 is a one-piece component made of a conductive material such as copper. However, it is also contemplated that the compression connector 10 may be made of any suitable conductive material or element that will withstand the crimping operation. figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com