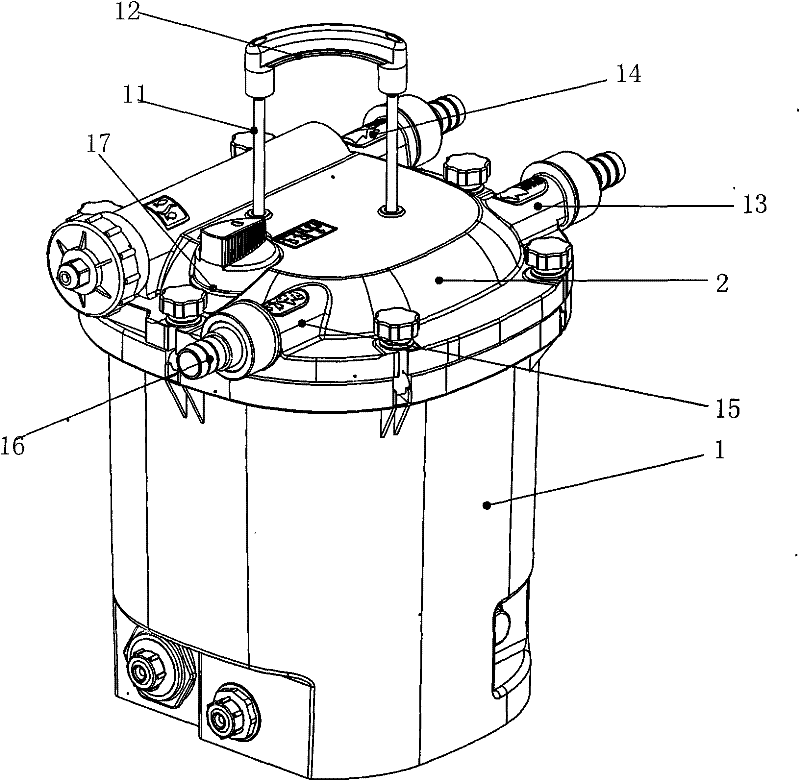

Filter structure

A technology of filters and filter elements, applied in membrane filters, fixed filter element filters, filtration circuits, etc., can solve the problems of inability to sterilize and disinfect aquaculture water, inconvenient cleaning and maintenance, etc., and achieve inhibition of algae growth and easy cleaning and maintenance , the effect of large filtration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

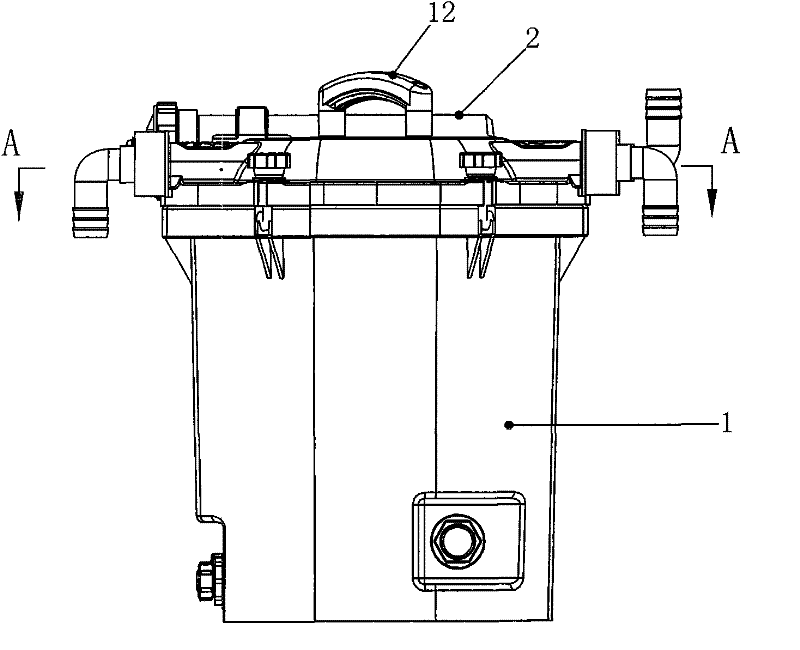

[0019] Reference Figure 1 to Figure 7 , The filter structure of the present invention includes a barrel body 1. A barrel cover 2 is installed on the barrel body 1. The barrel cover 2 can be installed on the barrel body 1 through a rotating rod 3 as shown in the figure, or through other installation structures Installed on the barrel 1, a sealing ring 4 is installed between the lid 2 and the barrel 1.

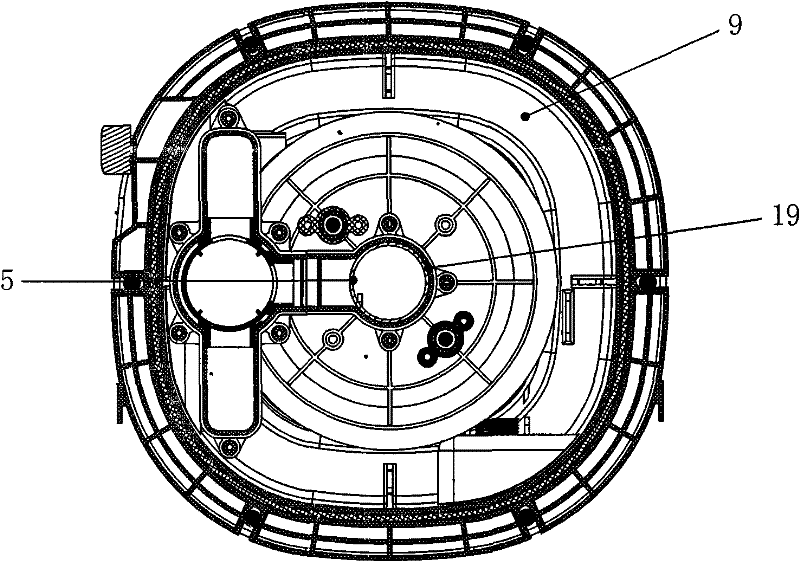

[0020] A filter tube 5 is installed in the barrel 1, a sealing plate 6 is installed on the top of the filter tube 5, a pipe plug 7 is installed at the bottom end of the filter tube 5, and a compressible filter core 8 is sleeved on the filter tube 5, which is compressible The filter element 8 can be formed by stacking different sizes of large-density filter cotton 81 and low-density filter cotton 82 at intervals. A liquid inlet space 9 is formed between the filter element 8 and the barrel 1, and the filter element is opposite to the filter element 8. The pipe 5 is provided with wa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap