Novel parallel composite yarn spinning device and spinning method

A composite yarn and equipment technology, applied in the direction of adhesives, etc., to achieve the potential and value of large market development, improve spinning efficiency, and shorten the effect of traditional technological processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention easier to be clearly understood, the following further describes the present invention in detail according to specific embodiments of the present invention in conjunction with the accompanying drawings.

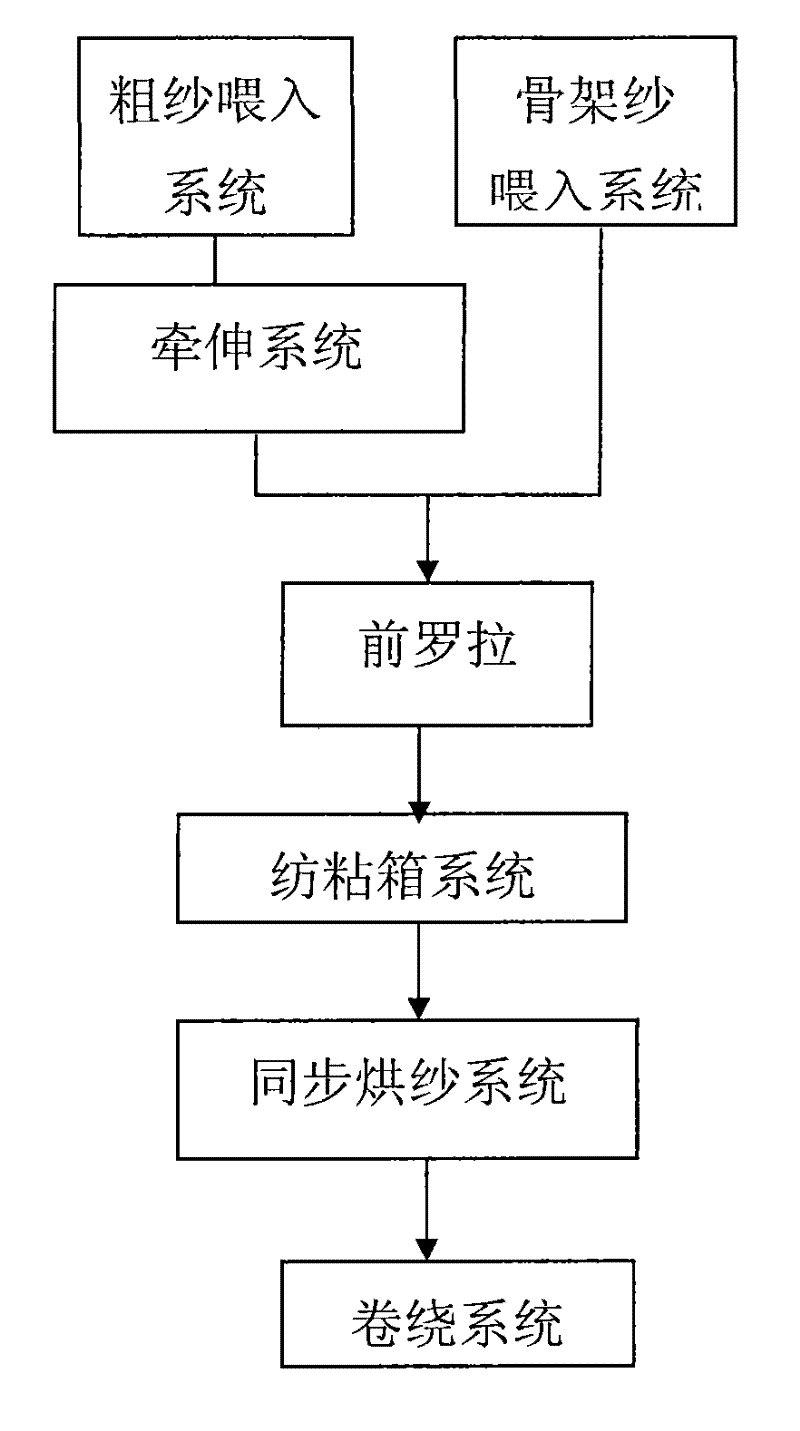

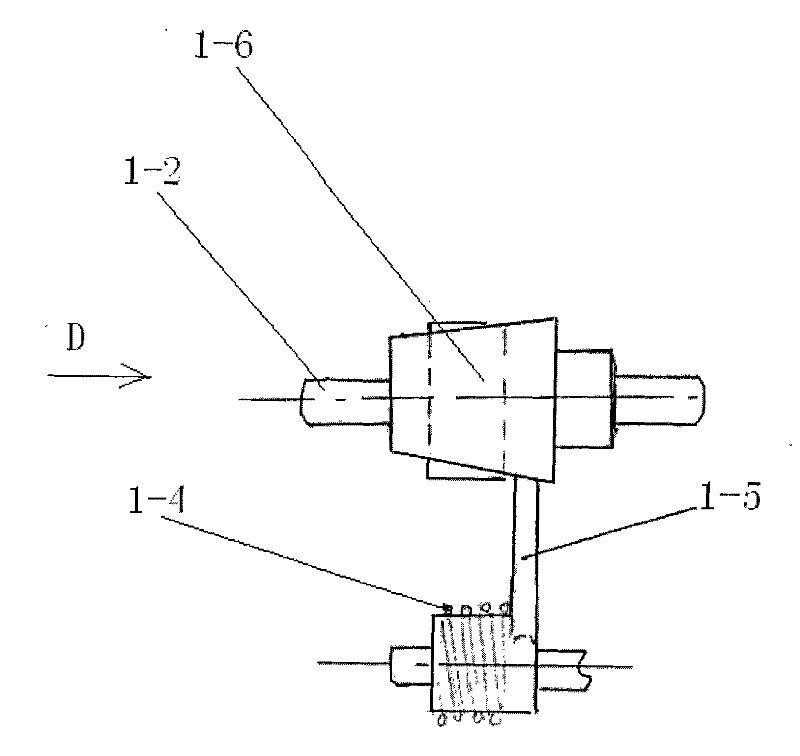

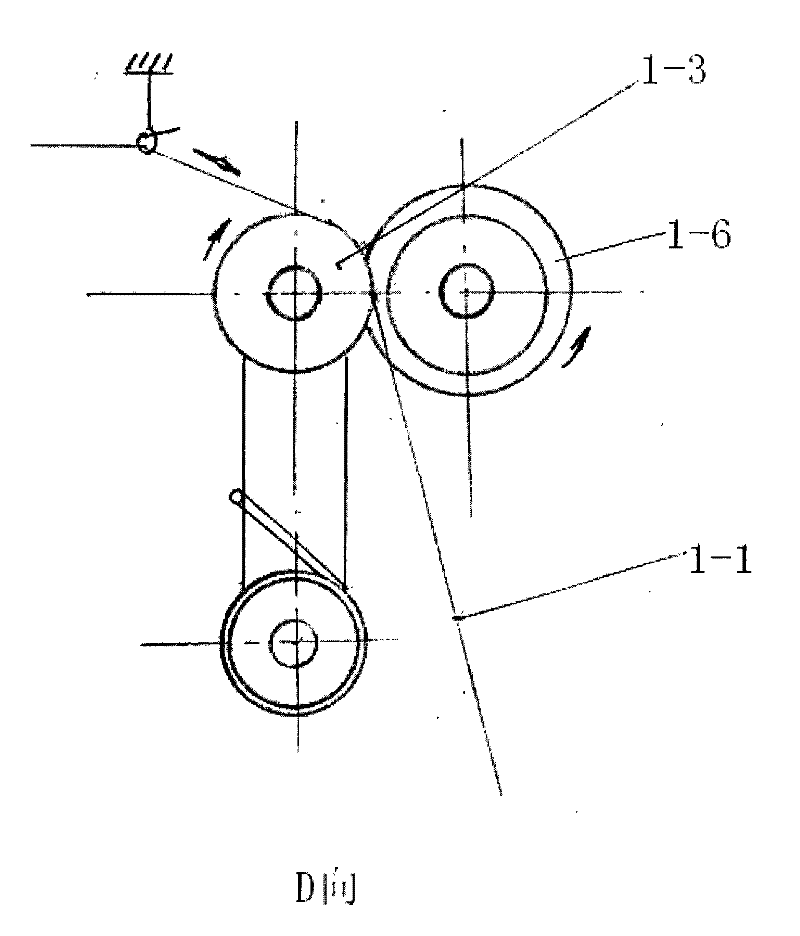

[0030] Such as figure 1 As shown, the present invention is a novel side-by-side composite yarn spinning equipment. The spinning equipment includes a roving feeding system, a skeleton yarn feeding system, a drafting system, a front roller, a spunbonding box system, a synchronous drying system and Winding system; the skeleton yarn feeding system is parallel to the roving feeding system connected to the downstream drafting system. The downstream of the skeleton yarn feeding system and the downstream of the drafting system are connected to the front roller at the same time, and the downstream of the front roller is connected to the spunbonding box system. The downstream of the spunbond box system is connected to the synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com