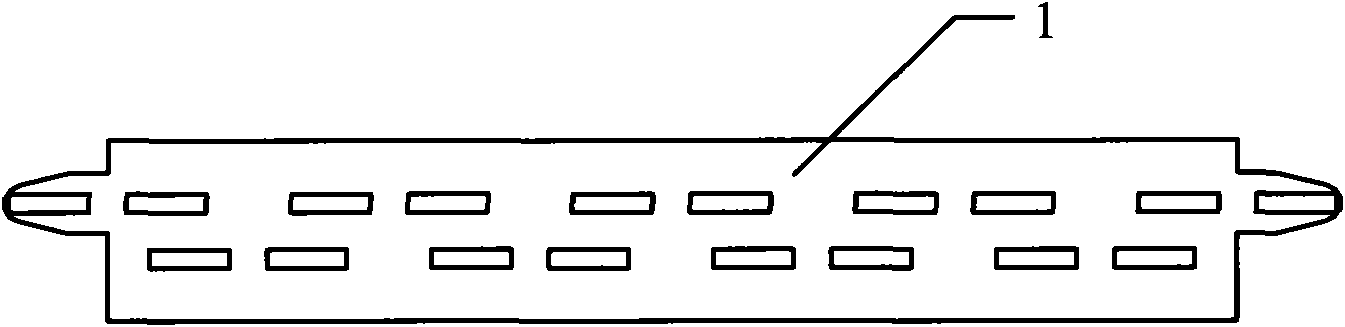

Stapling head of non-closed surgical stapling machine

A closed-loop, device-based technology, applied in the field of medical devices, can solve problems such as fracture nail line coverage, hidden dangers of patients' operations, incomplete closure of broken ends, etc., and achieve the effect of eliminating hidden dangers of incomplete closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

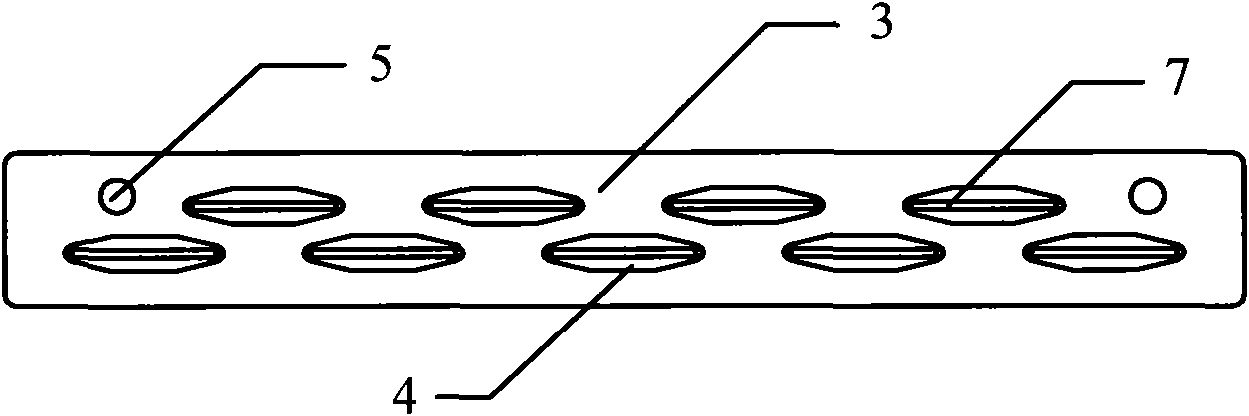

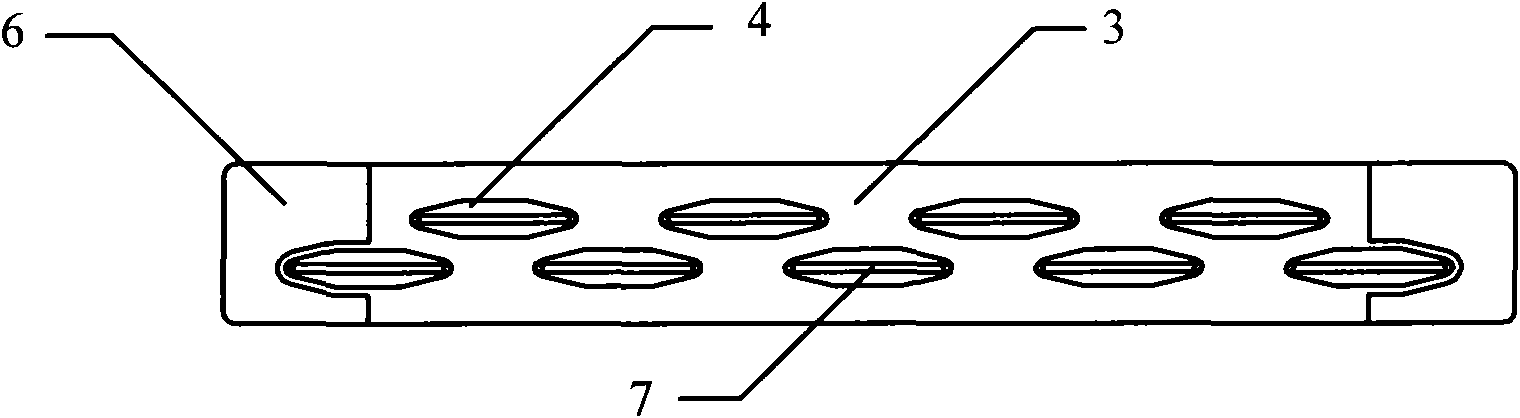

[0025] Both ends of the nailing line are provided with a limit device, which is a limit rod 6. The assembly process of the present invention is roughly as follows: firstly, the limiting rod 6 is passed through the limiting hole 5 on the staple cartridge 3 , so that the limiting rod 6 is combined with the staple cartridge 3 . Then, the staple cartridge 3 is installed on the far end of the staple pusher 2, and at the same time, the proximal end of the staple pusher 2 is installed on the binding instrument, and the limit rod 6 is connected with the corresponding control structure of the binding instrument. Next, the anvil 1 is installed on the anvil shaft, and the anvil shaft is connected to the binding instrument. Finally, it is enough to place the staples 7 in the staple cartridge holes 4 .

[0026] During the operation: first place the tissue 8 between the anvil 1 and the staple cartridge 3 , and then close the limiting rod 6 so that the tissue 8 is limited between the limiti...

Embodiment 2

[0029] Both ends of the nailing line are provided with limit devices, which are limit blocks. During manufacture, the limit block and the staple cartridge 3 can be integrally cast. The assembly process of the present invention is roughly as follows: first, the staple cartridge 3 is installed on the far end of the staple pusher 2, and then the proximal end of the staple pusher 2 is installed on the binding instrument. Next, the anvil 1 is installed on the anvil shaft, and the anvil shaft is connected to the binding instrument. Finally, place staples 7 in the staple bin holes 4 and get final product. Its usage is the same as that in Embodiment 1, and will not be repeated here.

[0030] It can be seen from the above text description and in conjunction with the accompanying drawings that after the present invention is adopted, the length of contact between the broken end of the tissue 8 and the surface of the staple cartridge can be completely covered by the nail, so that after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com