Directly sealed steel drum and sealing and fixing methods

A direct, profiled technology for sealing, transport and packaging, rigid containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

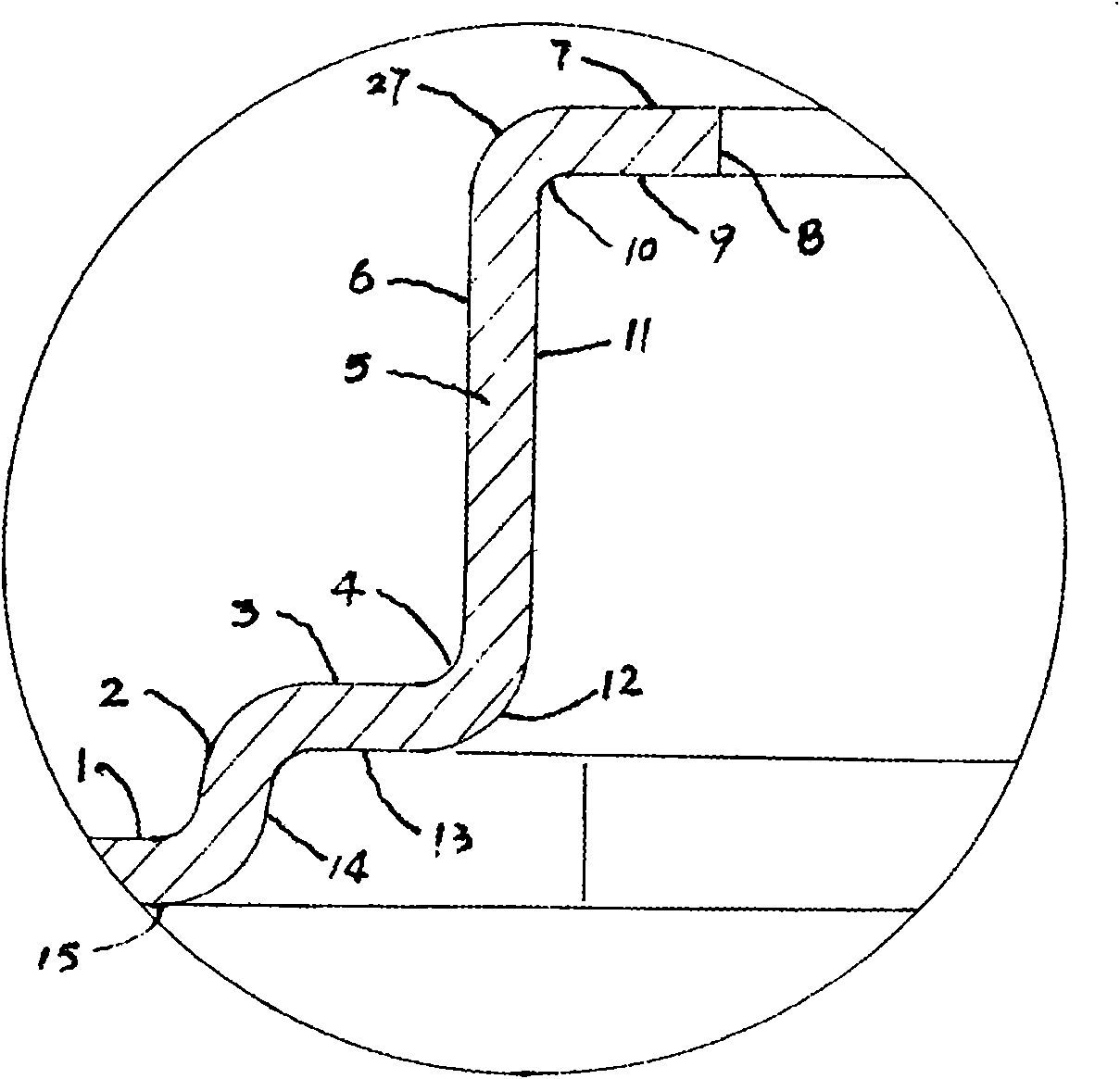

[0026] image 3 : It is a partial cross-sectional view of the octagonal boss 5 on the top of the barrel with the boss edge 7 of the directly sealed type steel drum embedded flange closure. There is an annular plane boss edge 7 and a process hole 8 on the top of the boss, and the barrel top The height of the octagonal boss 5 is 14.0 millimeters, and the width of the boss side 7 is 4.5 millimeters. It is formed by punching and stretching the barrel top cover 1. Since the mechanical properties of the stretched material have a great influence on the future forming size, the convex The width of the table edge 7 and the exact size of the process hole 8 should be determined by the materials used.

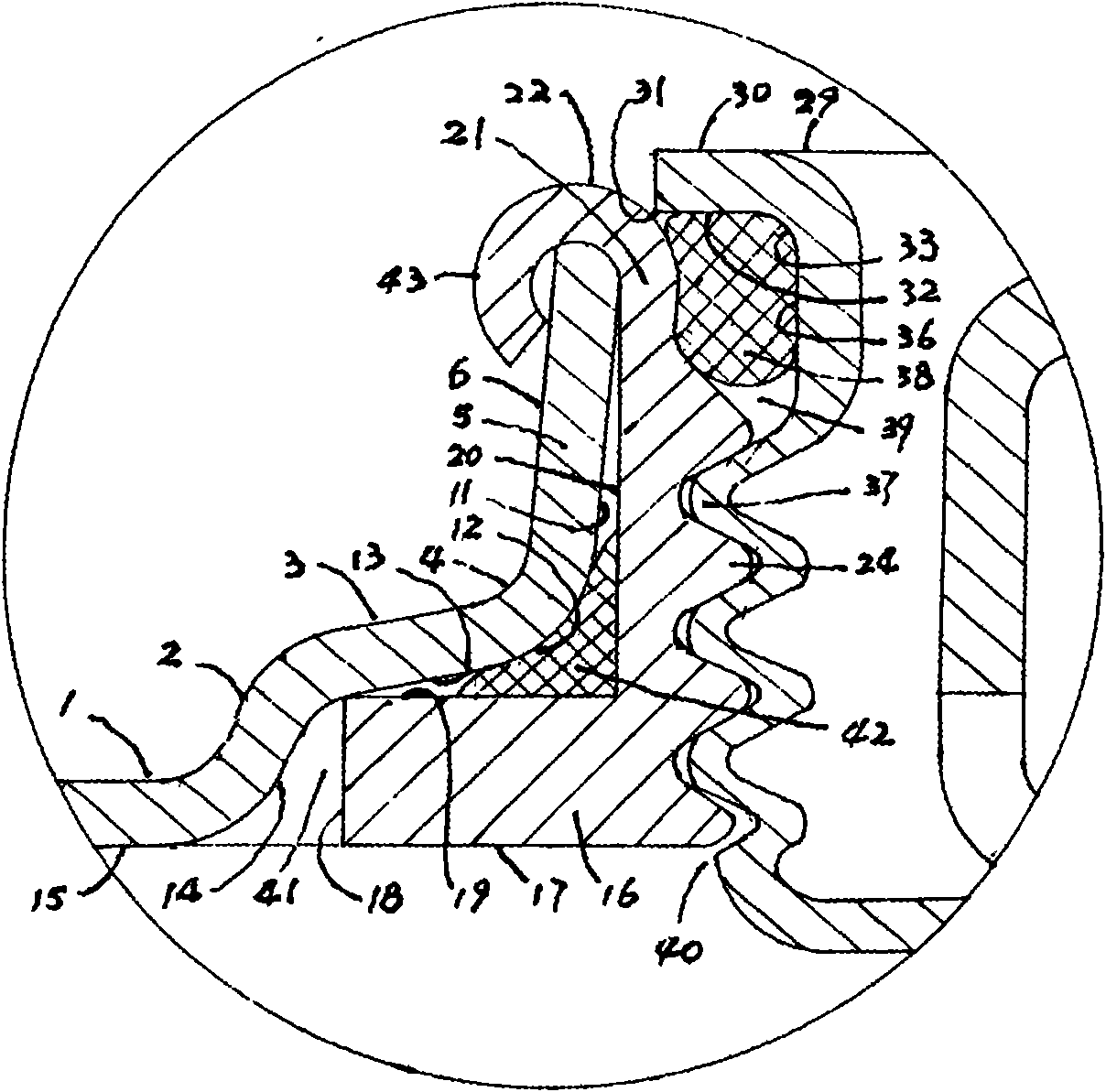

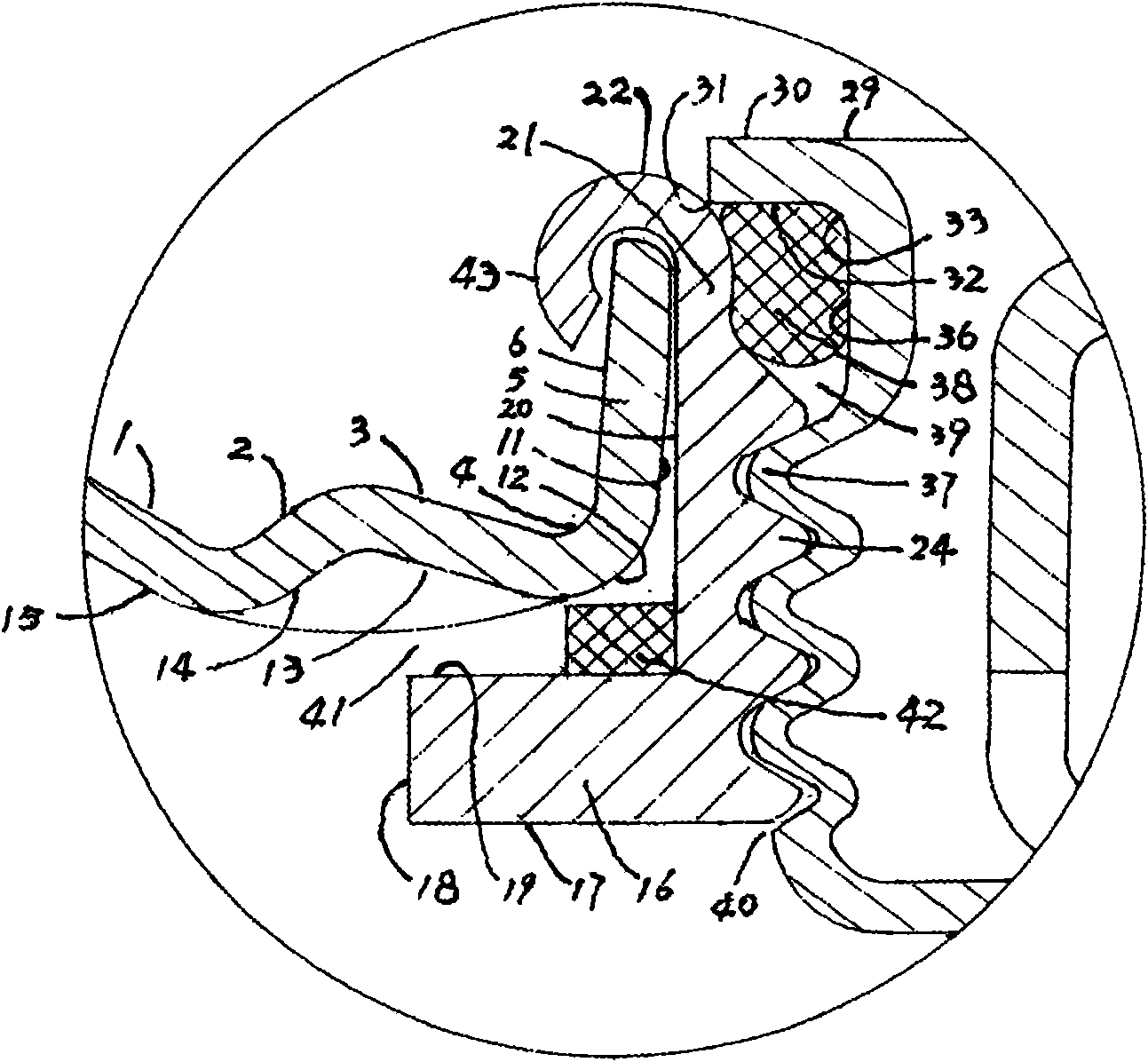

[0027] Figure 4 : It is a partial cross-sectional view of the octagonal boss 5 on the top of the barrel with the boss edge 7 and the flange ring 16 before the inner and outer octagons are embedded for the directly sealed type steel drum embedded flange sealer. Due to the flange ring 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com