Steel roof system

A steel roof and steel roof truss technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of small span and large steel consumption, achieve the goal of reducing steel consumption, improving the scope of application, and ensuring mechanical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

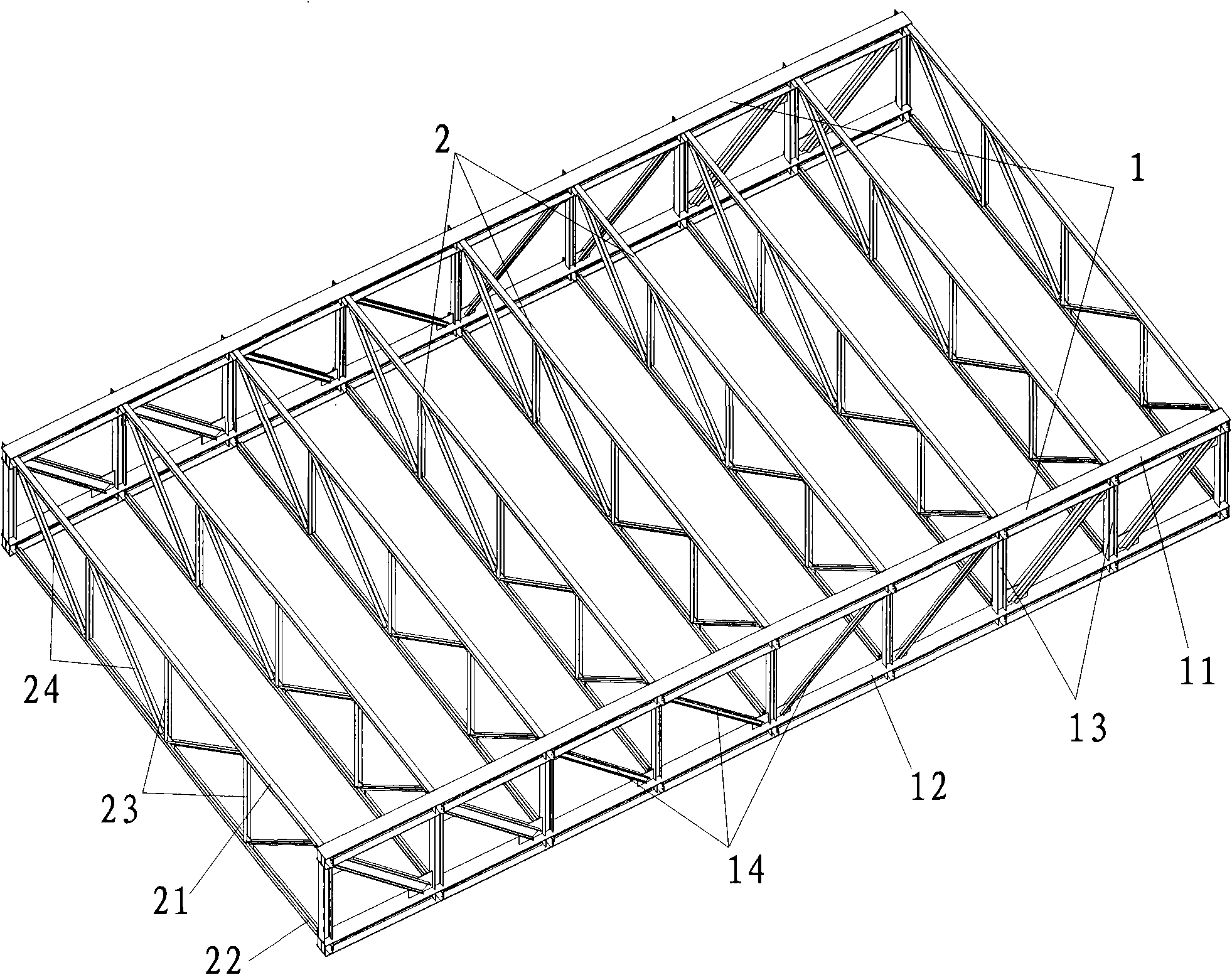

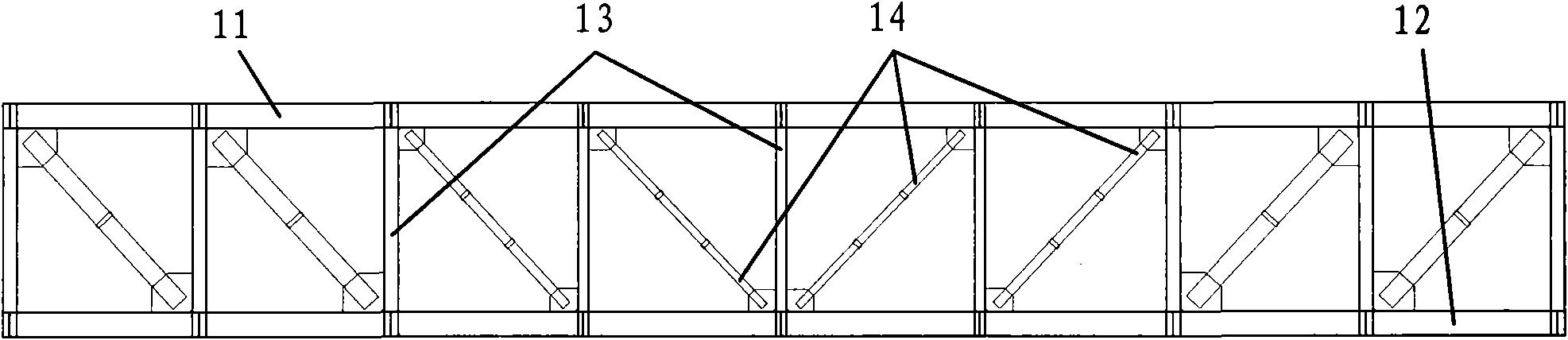

[0066] E.g: figure 1 In the steel roof system shown, the steel roof truss is parallel chord steel roof truss 1, and the connecting truss is parallel chord truss 2. Preferably, at least two parallel chord trusses 2 are arranged between every two adjacent parallel chord steel roof trusses 1 . in, figure 1 The steel roof system shown in takes two parallel chord steel roof trusses 1 and several parallel chord trusses 2 connecting the two parallel chord steel roof trusses 1 as an example.

[0067] figure 1 The two parallel-chord steel roof trusses 1 are arranged in parallel, the two ends of the upper chords 21 of the parallel-chord trusses 2 are respectively connected with the upper chords 11 of the two adjacent parallel-chord steel roof trusses 1, and the two lower chords 22 of the parallel-chord trusses 2 The two ends of each are respectively connected to the lower chords 12 of two parallel chord steel roof trusses 1 arranged adjacently.

[0068] Several typical arrangements ...

Embodiment 2

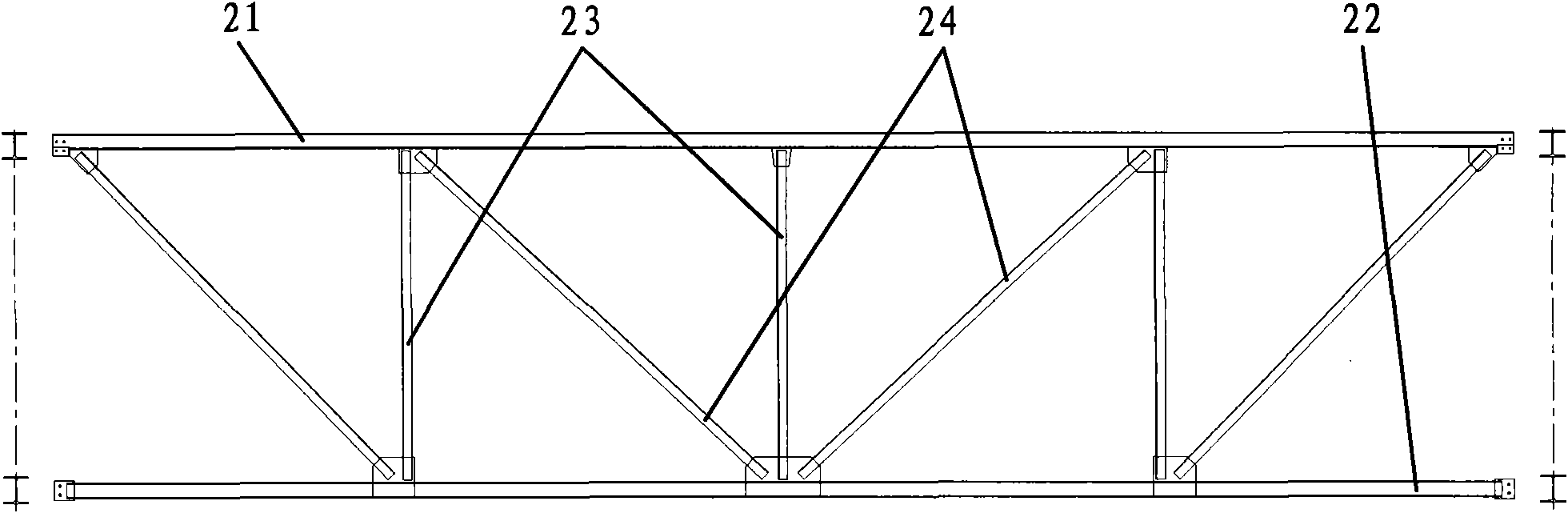

[0116] E.g: Figure 17 In the steel roof system shown, the steel roof truss is parallel chord steel roof truss 1, and the connecting truss is parallel chord truss 2. Preferably, at least two parallel chord trusses 2 are arranged between every two adjacent parallel chord steel roof trusses 1 . in, Figure 17 The steel roof system shown in takes two parallel chord steel roof trusses 1 and several parallel chord trusses 2 connecting the two parallel chord steel roof trusses 1 as an example.

[0117] The parallel chord steel roof truss 1 includes upper chords 11 and lower chords 12 arranged in parallel, and support rods (including vertical webs 23 and / or diagonal webs 24 ) connecting the upper and lower chords ( 11 , 12 ). The parallel chord truss 2 comprises an upper chord 21 and a lower chord 22 arranged in parallel, a support rod (comprising a vertical web 23 and / or a diagonal 24) connecting the upper and lower chords (21, 22), and one end and the lower chord 22 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com