Method for determining load-life curve and working life of component

A technology of working life and life curve, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve the problems of high cost, high test cost, narrow application range of test data, etc., and achieve the effect of saving time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

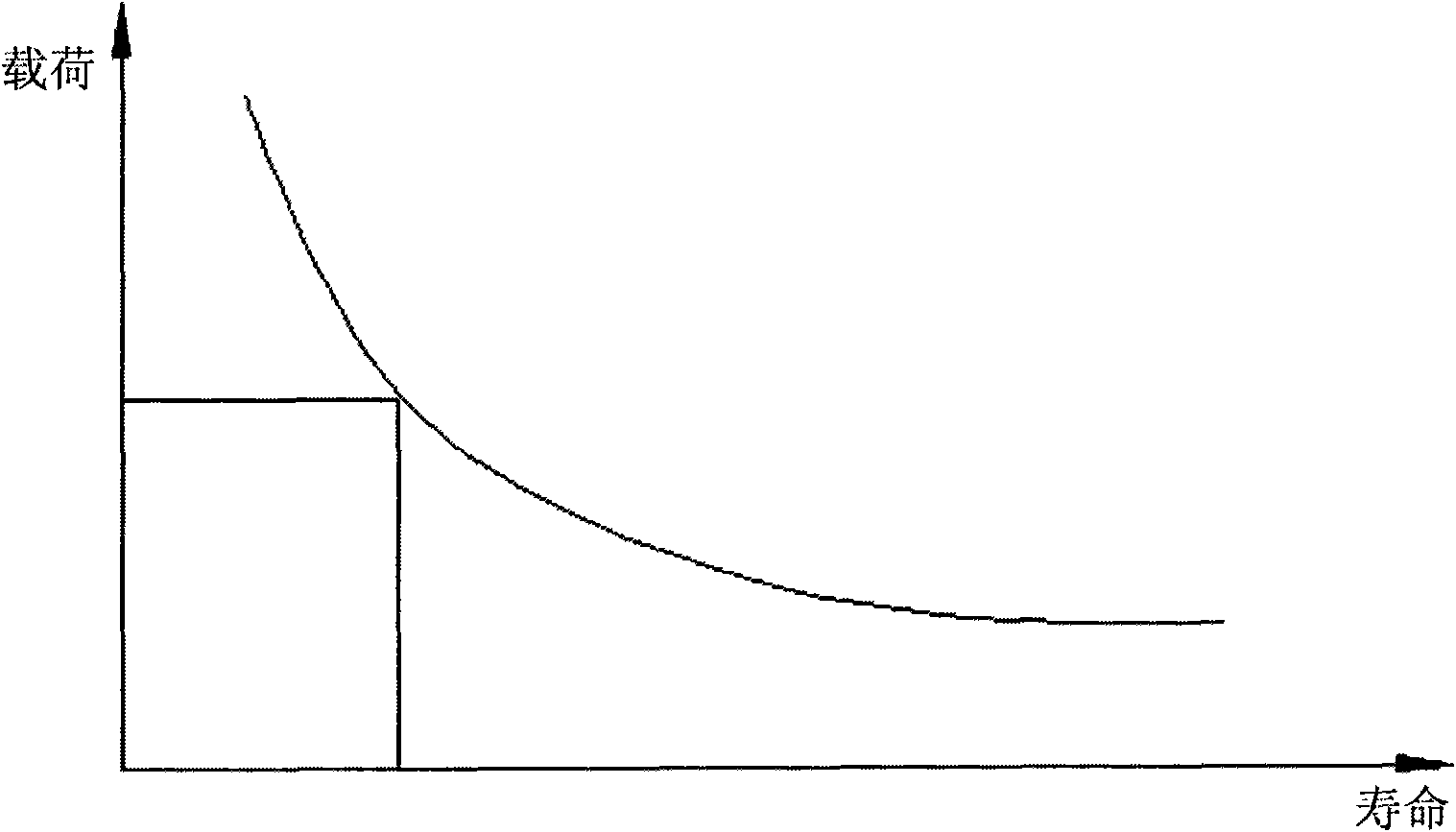

[0032] The method of using infrared thermal imaging technology to quickly determine the component load-life curve and estimate the working life of the component according to the curve provided by the present invention includes the following steps:

[0033] First, according to the existing mechanical parameters of the component material (such as the tensile strength or fatigue limit of the component material), the fatigue limit of the component is preliminarily estimated, and the load spectrum of the component under actual working conditions is compiled statistically.

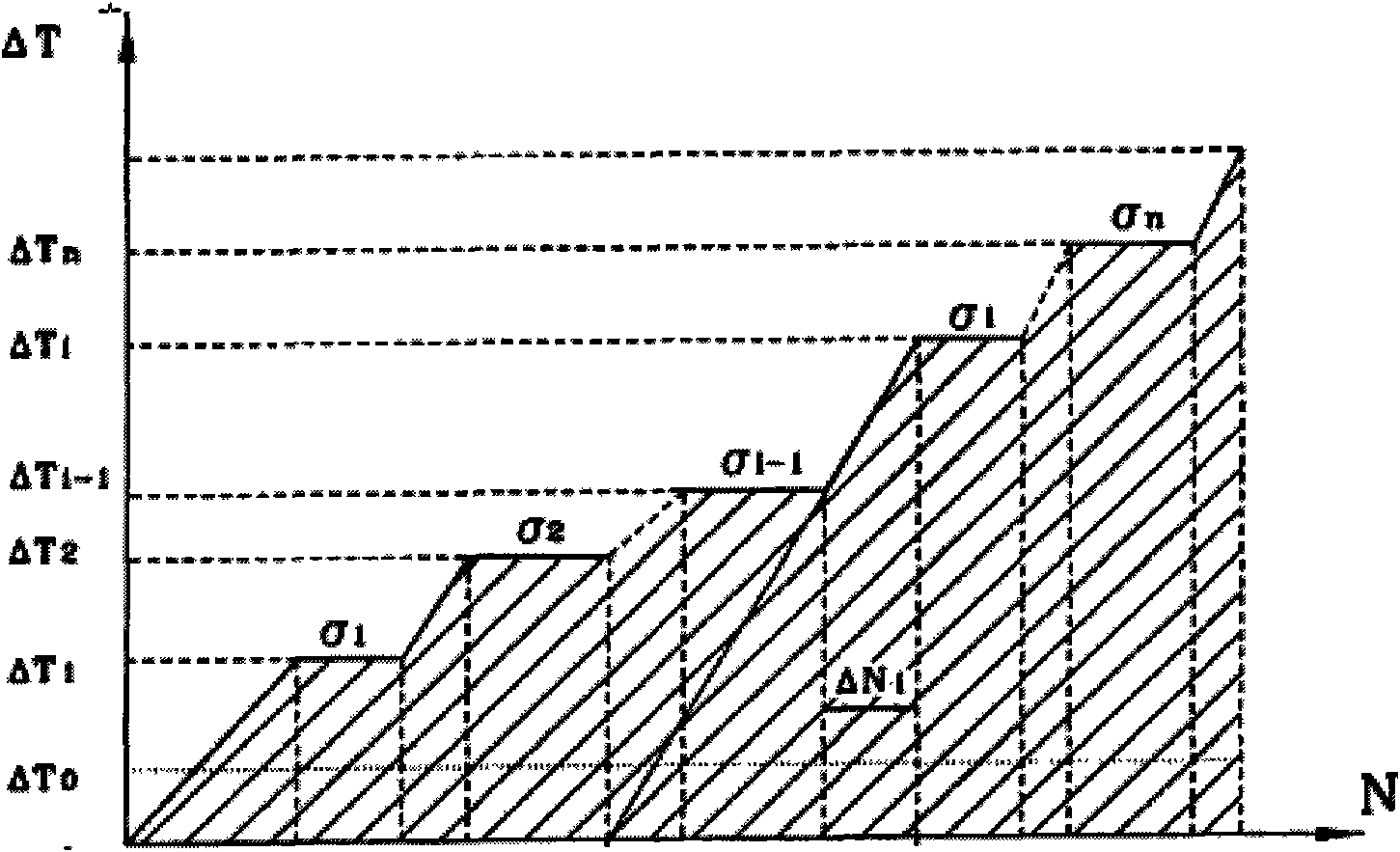

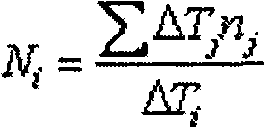

[0034] Then, a constant amplitude fatigue test was started on the component below 20% of the estimated fatigue limit of the component, and the infrared camera was used to observe the temperature change on the surface of the component in real time during the test.

[0035] When the temperature is stable, increase the test load to continue the test. The load increase refers to the material properties of the component ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap