Cable connector assembly

A cable connector, cable technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problems of increasing manufacturing cost, high mold requirements, easy-to-break conductive materials, etc., to reduce friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

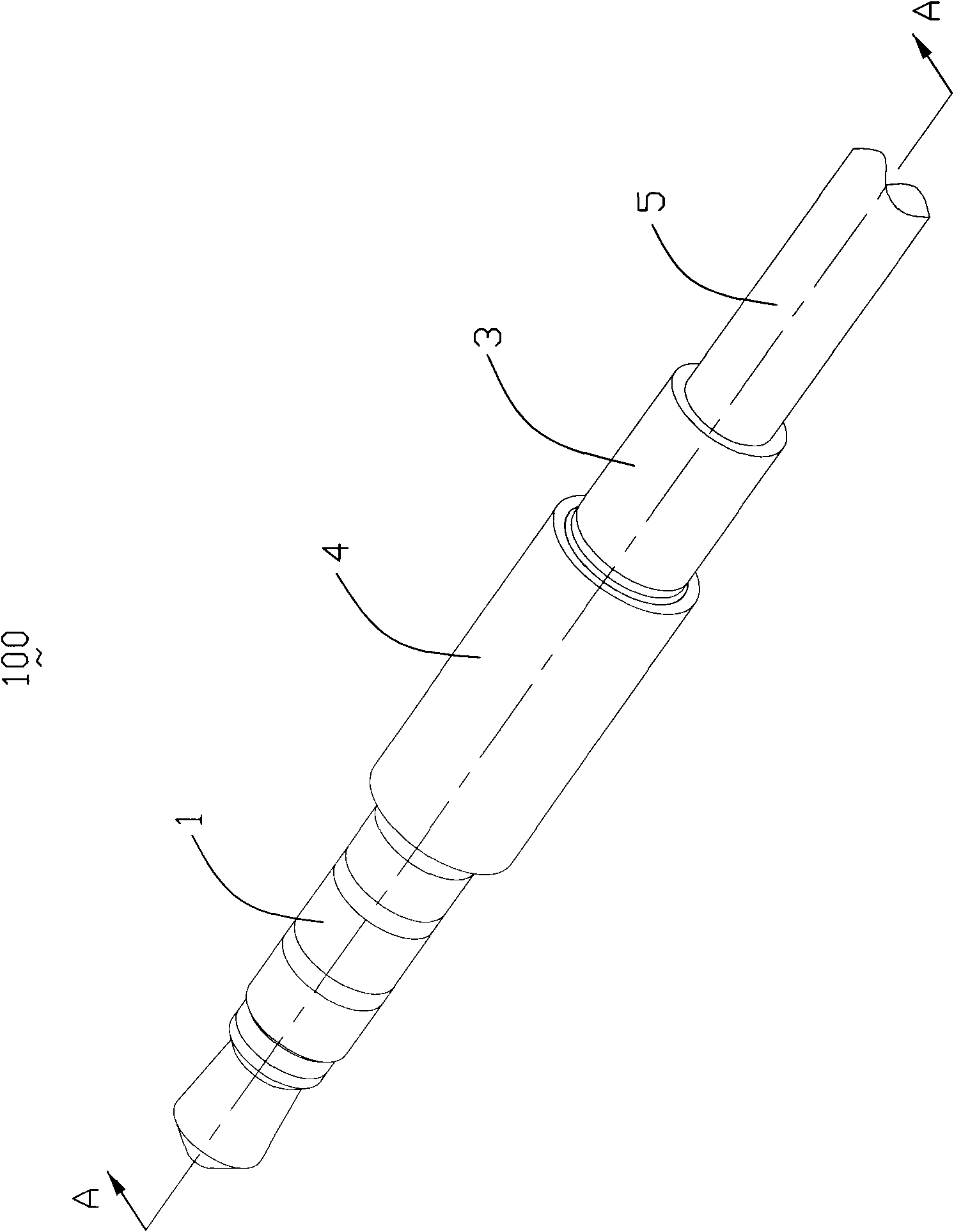

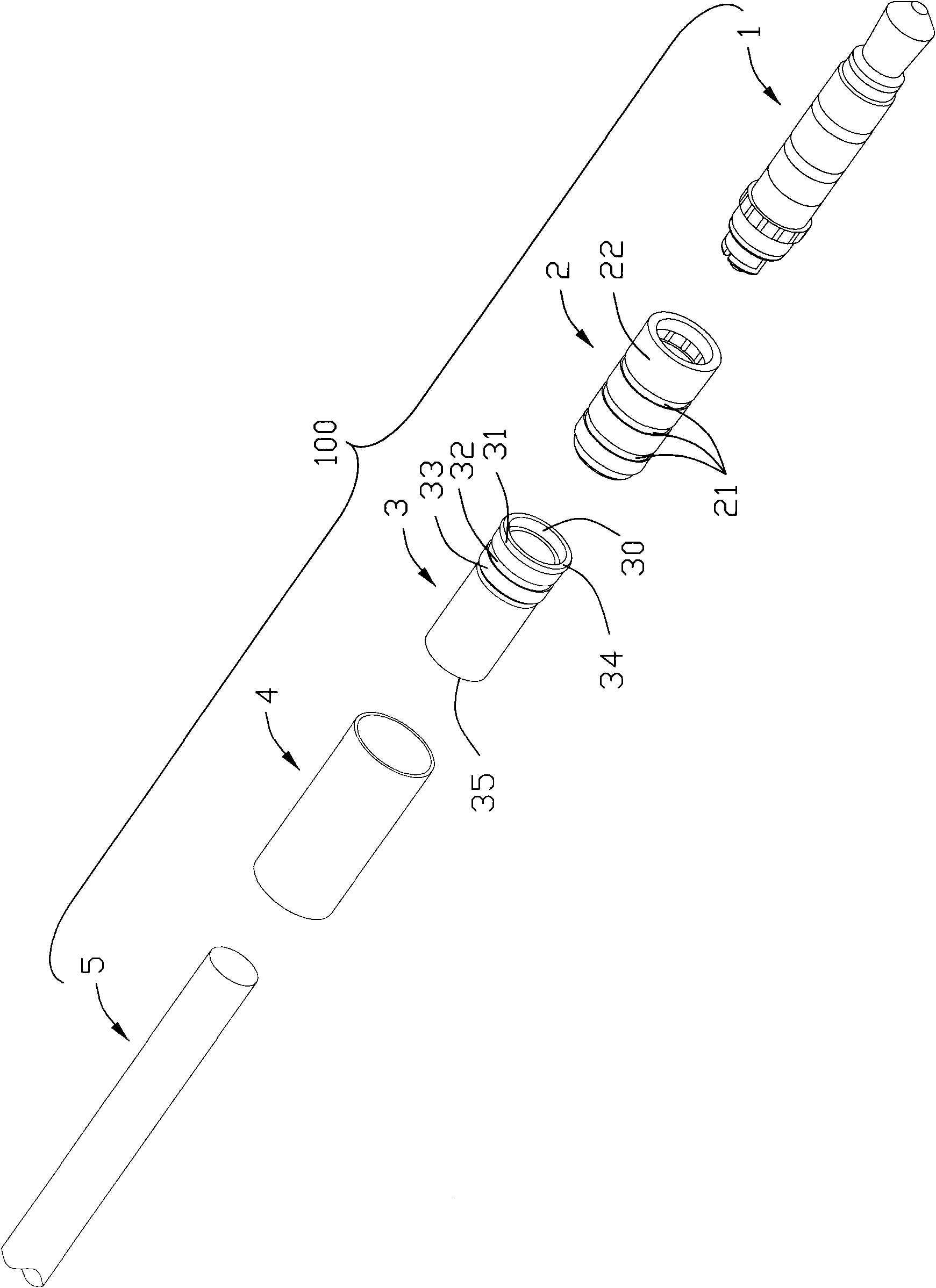

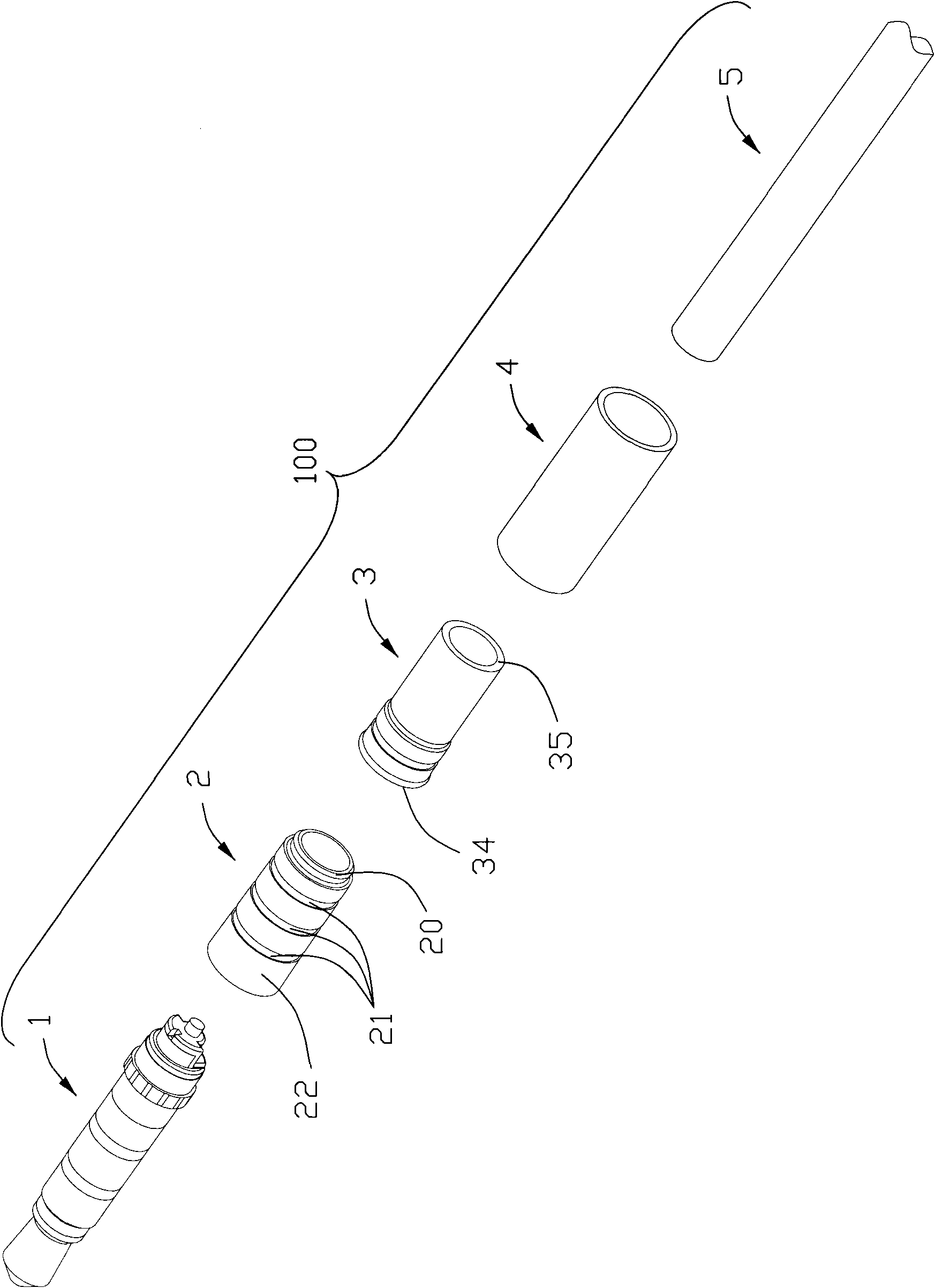

[0014] see Figure 1 to Figure 6 , the cable connector 100 of the present invention is an audio transmission connector for connecting electronic devices such as MP3 players. The cable connector 100 includes a plug 1 , a holding tube 2 , a flexible sleeve 3 , an assembly tube body 4 and a cable 5 . Wherein, one end of the plug 1 is accommodated in the holding tube 2 and connected to the cable 5 , and the other end of the plug 1 is used as a contact end to connect with the electronic device. The holding tube 2 and the flexible sleeve 3 are combined into a whole for receiving the plug 1 and the cable 5 which are connected to each other. The assembly pipe body 4 is covered on the holding pipe 2 and the flexible sleeve 3 assembled with each other, and the length of the assembly pipe body 4 is longer than the holding pipe 2, but longer than the holding pipe 2 and the flexible sleeve 3 after assembly. The overall length should be small.

[0015] see figure 2 and image 3 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com