Double-mould vulcanizing machine

A vulcanizing machine and vulcanizing chamber technology, applied in the field of rubber machinery, can solve the problems of easy damage to the tire lifting device, limited sealing effect and high maintenance cost, and achieve the effects of stable machine performance, novel and beautiful appearance, and reasonable stress structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to overcome the above problems in the prior art, the present invention provides a new double-mode vulcanizer. Next, the dual-mode vulcanizer will be specifically described.

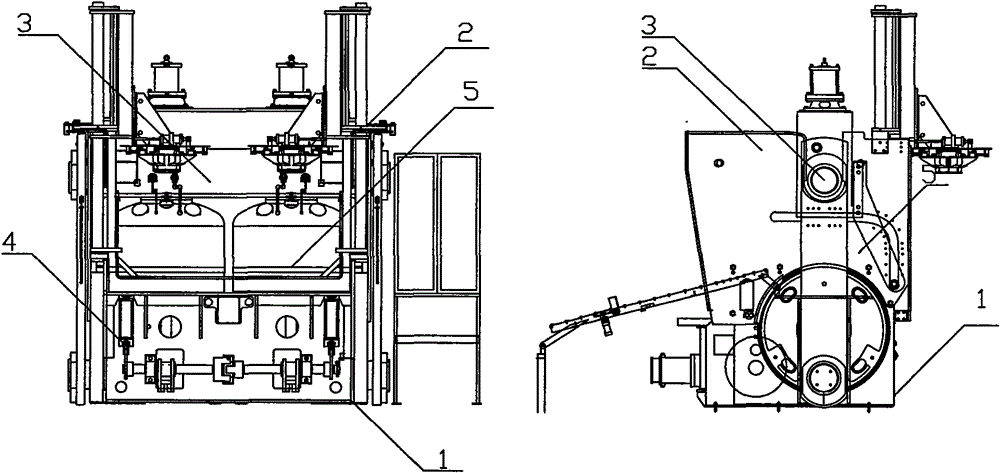

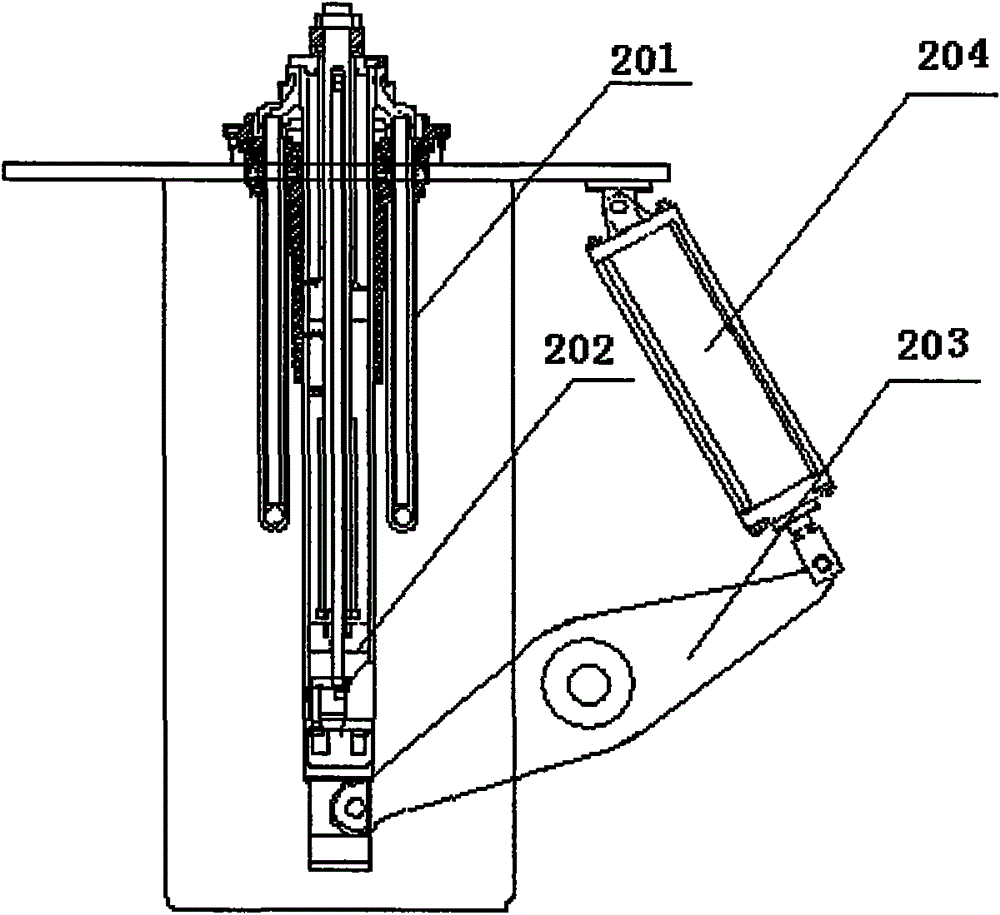

[0034] Figure 5 The switchboard device structure of the present invention is shown. Such as figure 1 As shown, the double-mode vulcanizing machine includes a base 1, wall panels 2 connected and fixed on both sides of the base, and a crossbeam 6 that is arranged across the wall panels on both sides and can be turned over along the guide rails 3 and / or guide rail grooves of the wall panels. , two vulcanization chambers 7 that hold raw tires and make it molded, drive the crossbeam 6 to carry out the transmission device 9 of overturning activity and be connected and fixed on the base 1 and lift the tire out of the vulcanization chamber 7 outside the vulcanized tires.

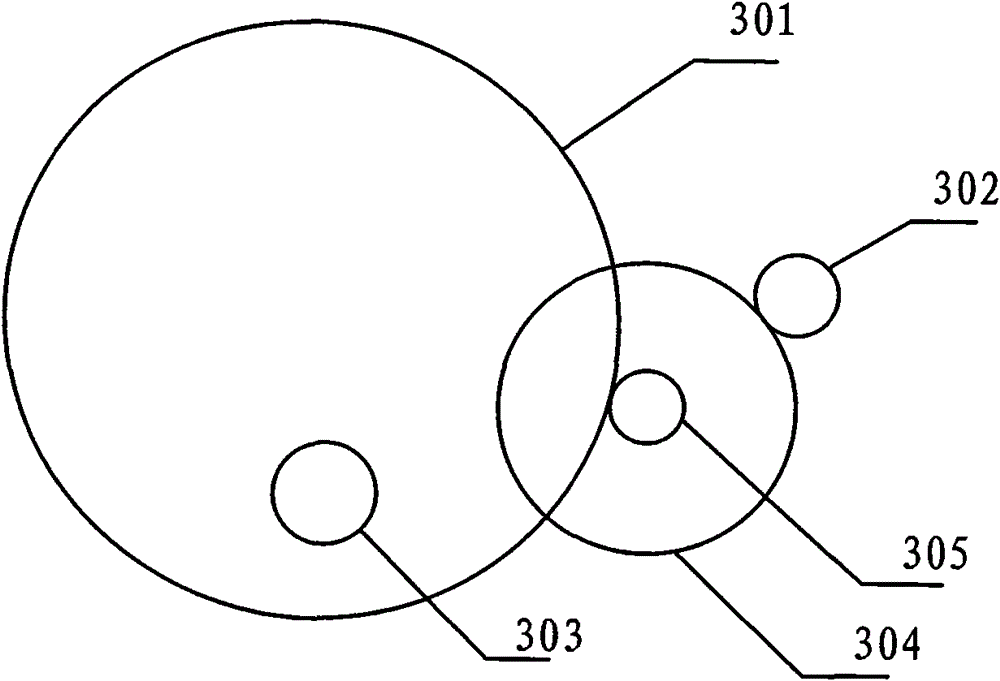

[0035] Wherein, the vulcanization chamber 7 is composed of an upper clamping mold and a lower clamping mold, the upper cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com