Method for monitoring axial force of scaffold upright rod

An axial force and scaffolding technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of axial force deviation, hidden danger, no pole calibration and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

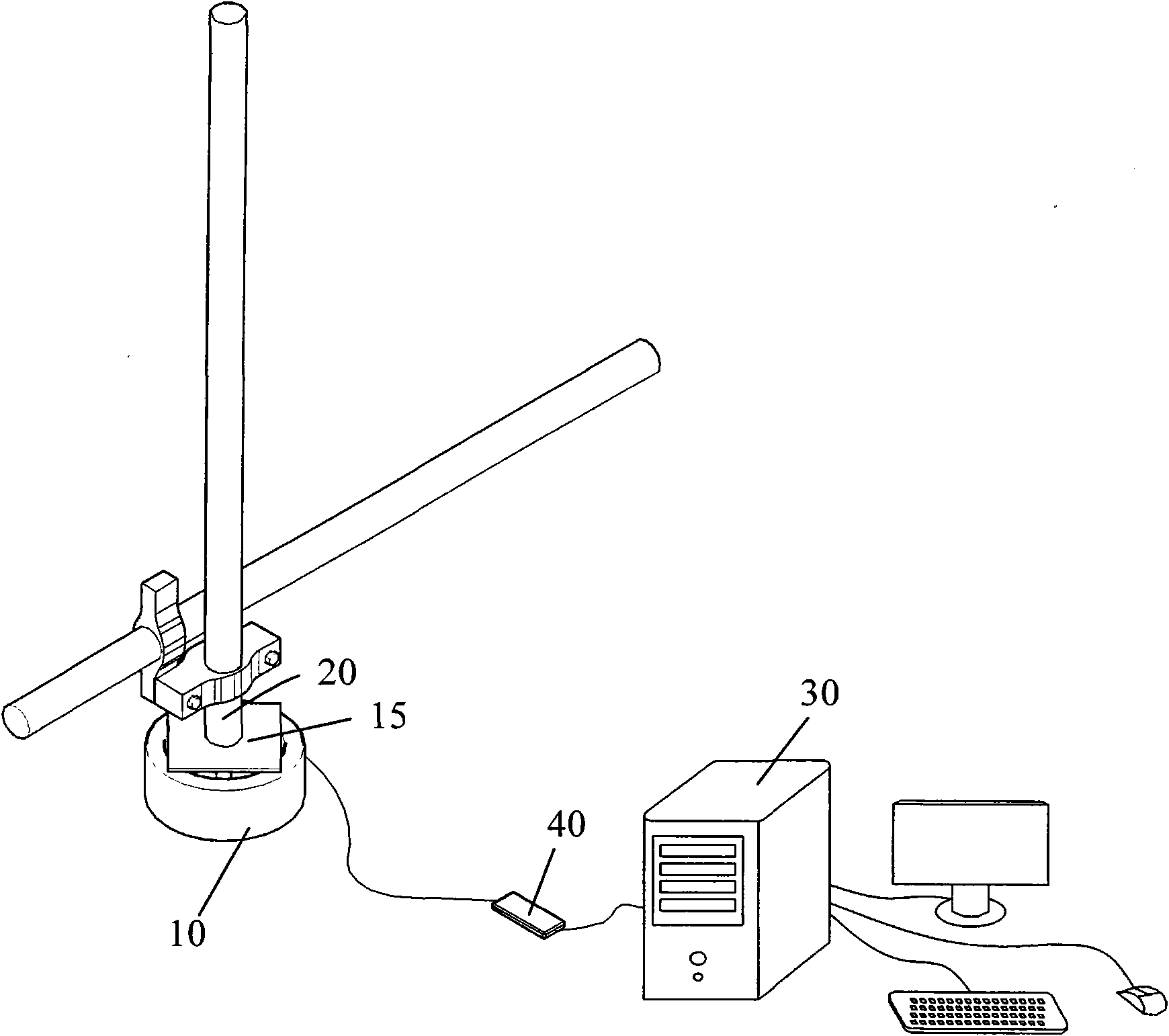

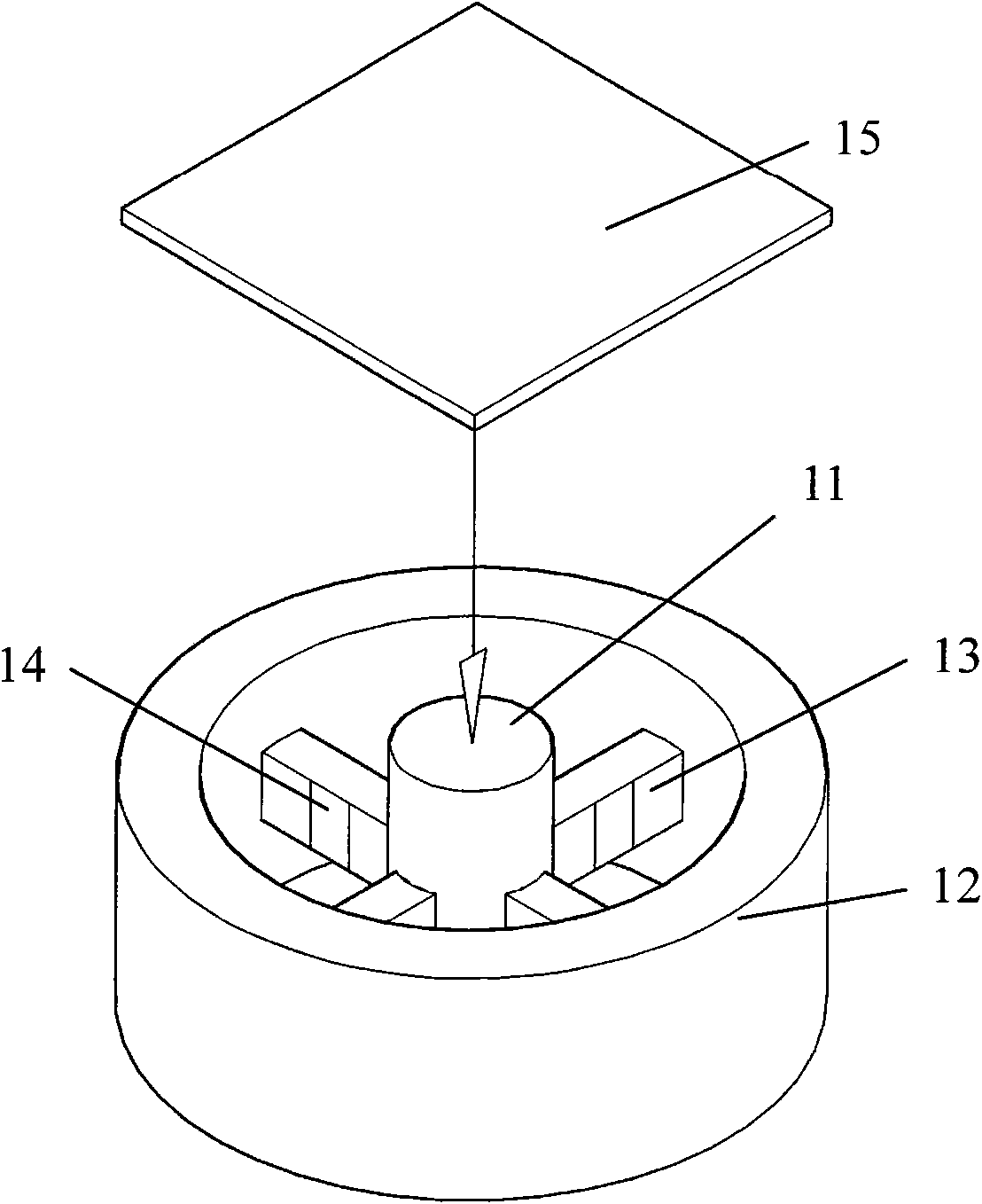

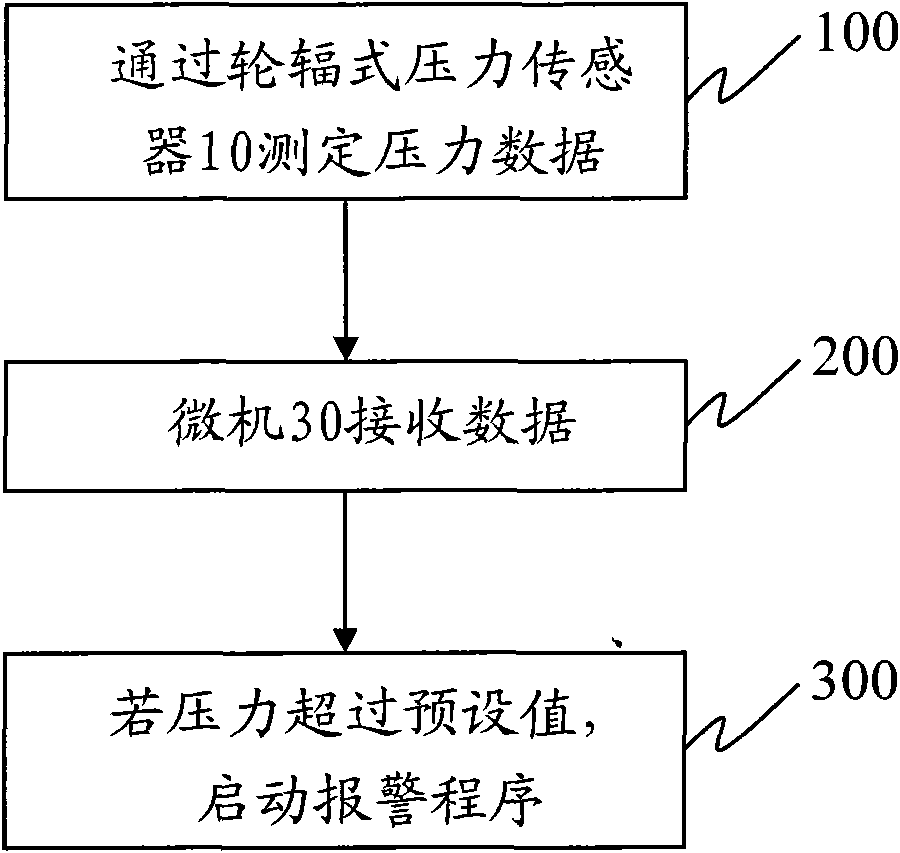

[0014] Such as figure 1 As shown, the pole axial force monitoring method of the present invention can be realized by the following devices: the spoke pressure sensor 10 is arranged on the bottom end of the scaffold pole 20; figure 2 As shown, the spoke-type pressure sensor 10 is in an oblate shape, and is mainly composed of a hub 11, a rim 12, a spoke 13, and a strain gauge 14 under pressure. A steel plate 15 is fixedly installed to support the vertical pole 20 by the steel plate 15; the microcomputer 30 is connected with the spoke pressure sensor 10 through a communication cable, and a data acquisition card 40 is also connected between the spoke pressure sensor 10 and the microcomputer 30. After the pressure data collected by the spoke pressure sensor 10 is converted from an analog signal into a digital signal, it is sent to the microcompute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com