Force-measurement type laminated rubber bearing based on optical fiber deformation sensor

A technology of plate-type rubber bearings and deformation sensors, which is applied to bridge parts, bridges, buildings, etc., can solve the problem that the inspection frequency and inspection effect of bridge bearings are not ideal, and the damage of bridge bearings cannot be found in time, and the bearings cannot be supported. Replacement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

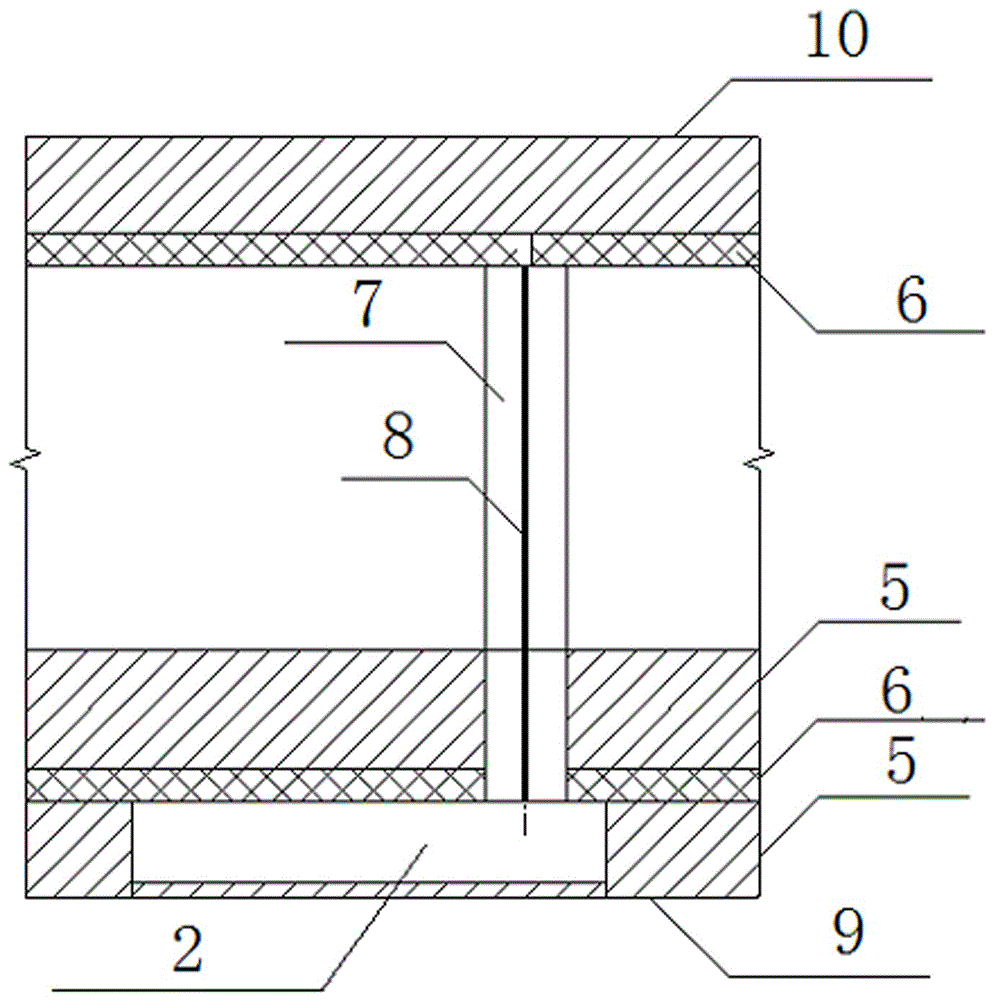

[0018] The mechanical characteristics of the plate rubber bearing are that it bears the large deformation caused by the dead load of the bridge superstructure for a long time, and the short-term (time-varying) bears the small deformation caused by the live load such as vehicle load. Under the bearing capacity of the bearing, the vertical strain can reach 10000~20000 με . Commonly used strain sensors are not suitable for this strain range, and a special design should be made so that the force monitoring device can adapt to the force characteristics of the support.

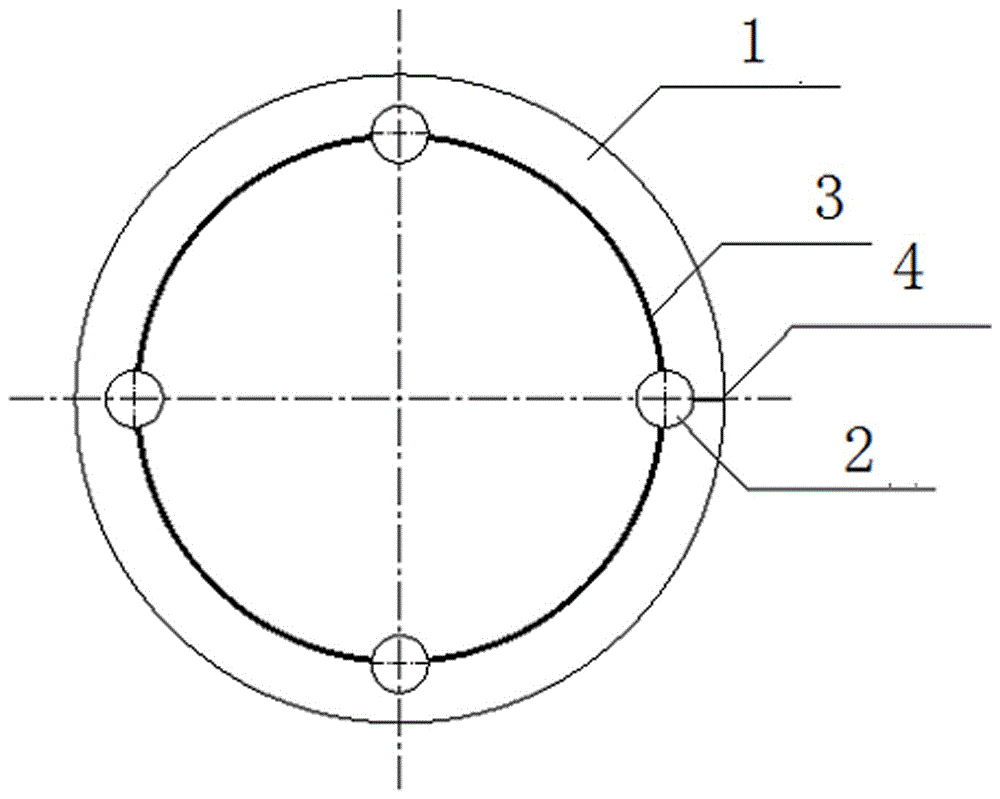

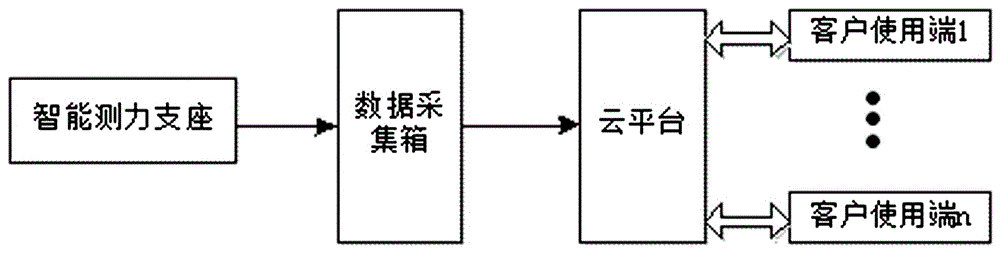

[0019] The technical solution of the present invention is: an intelligent force-measuring plate rubber bearing based on an optical fiber deformation sensor, including a plate rubber bearing body 1, the rubber bearing includes several rubber layers arranged at intervals, two adjacent rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com