Spring umbrella with built-in umbrella cover

A built-in, umbrella surface technology, applied in the field of spring umbrellas, can solve the problems of complex structure and arrangement, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

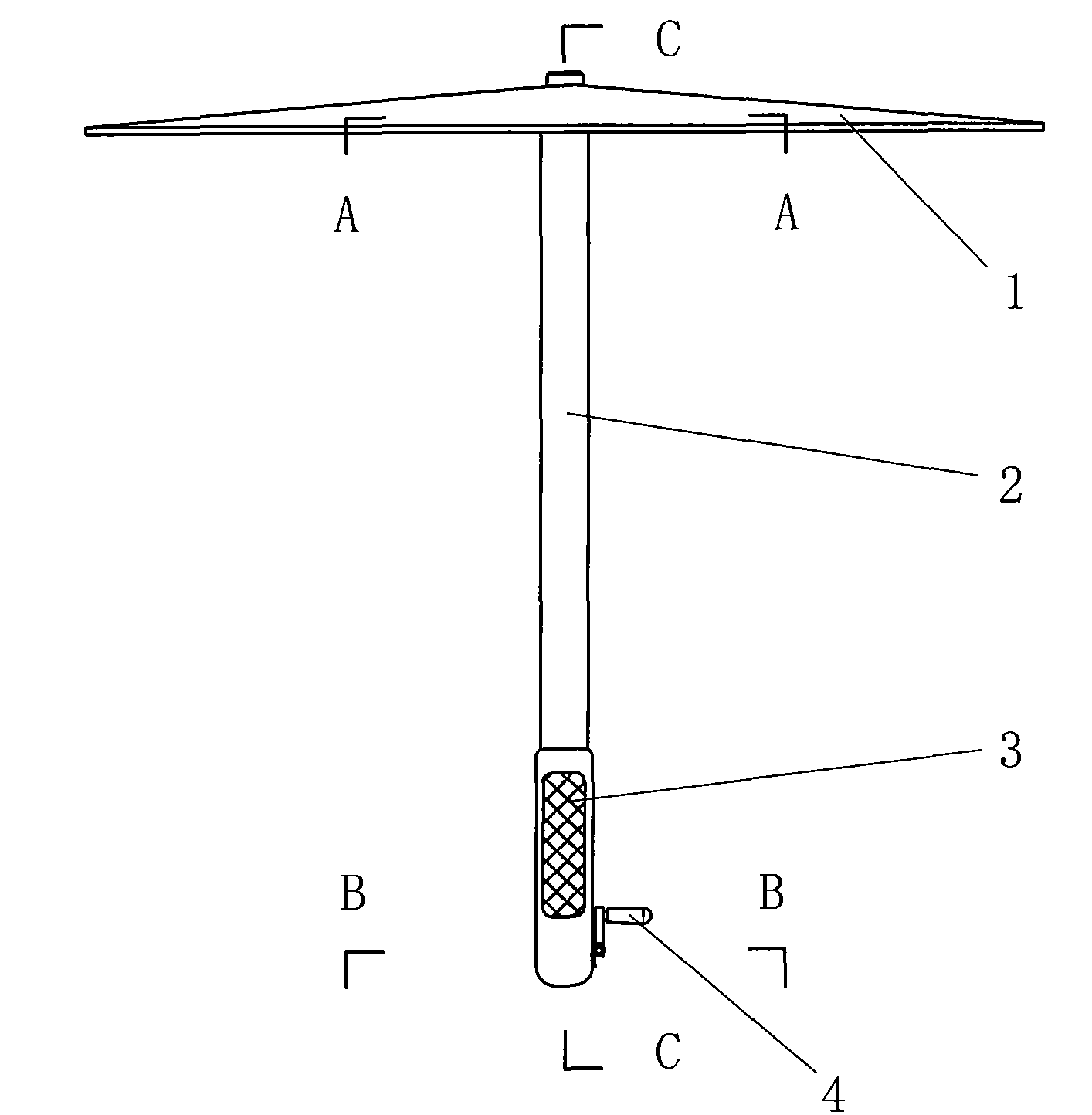

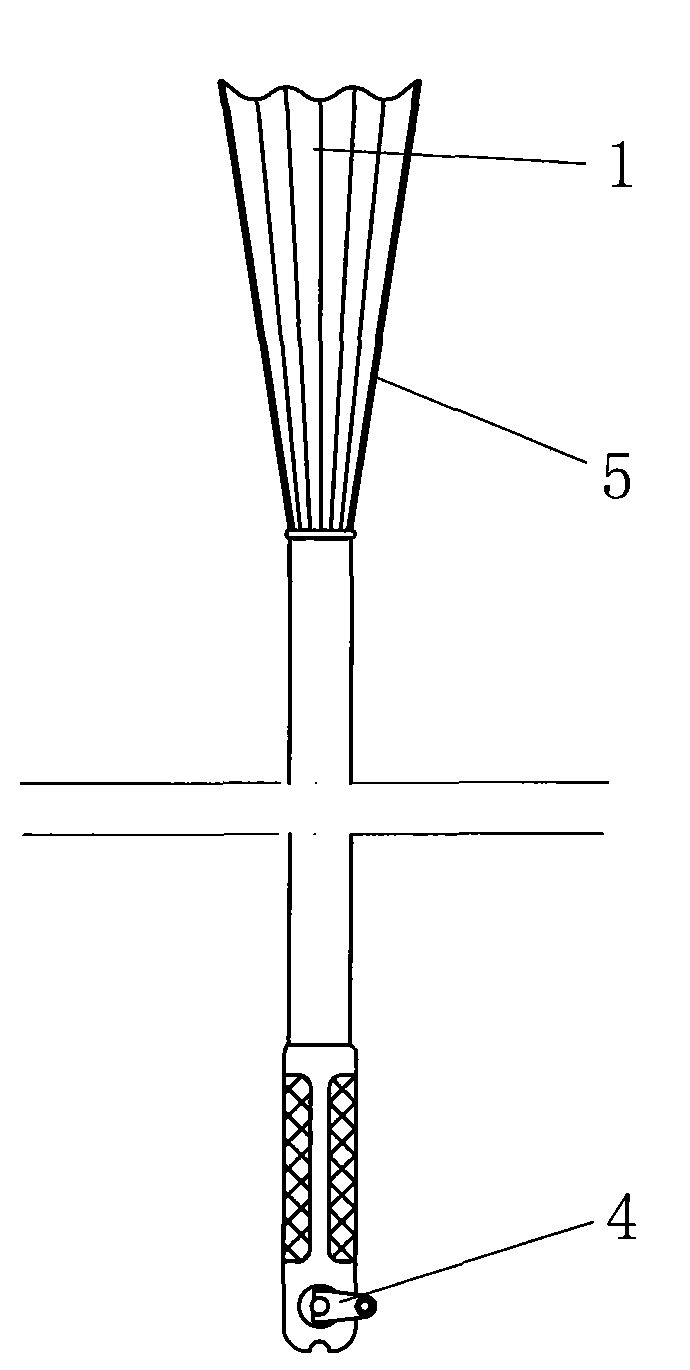

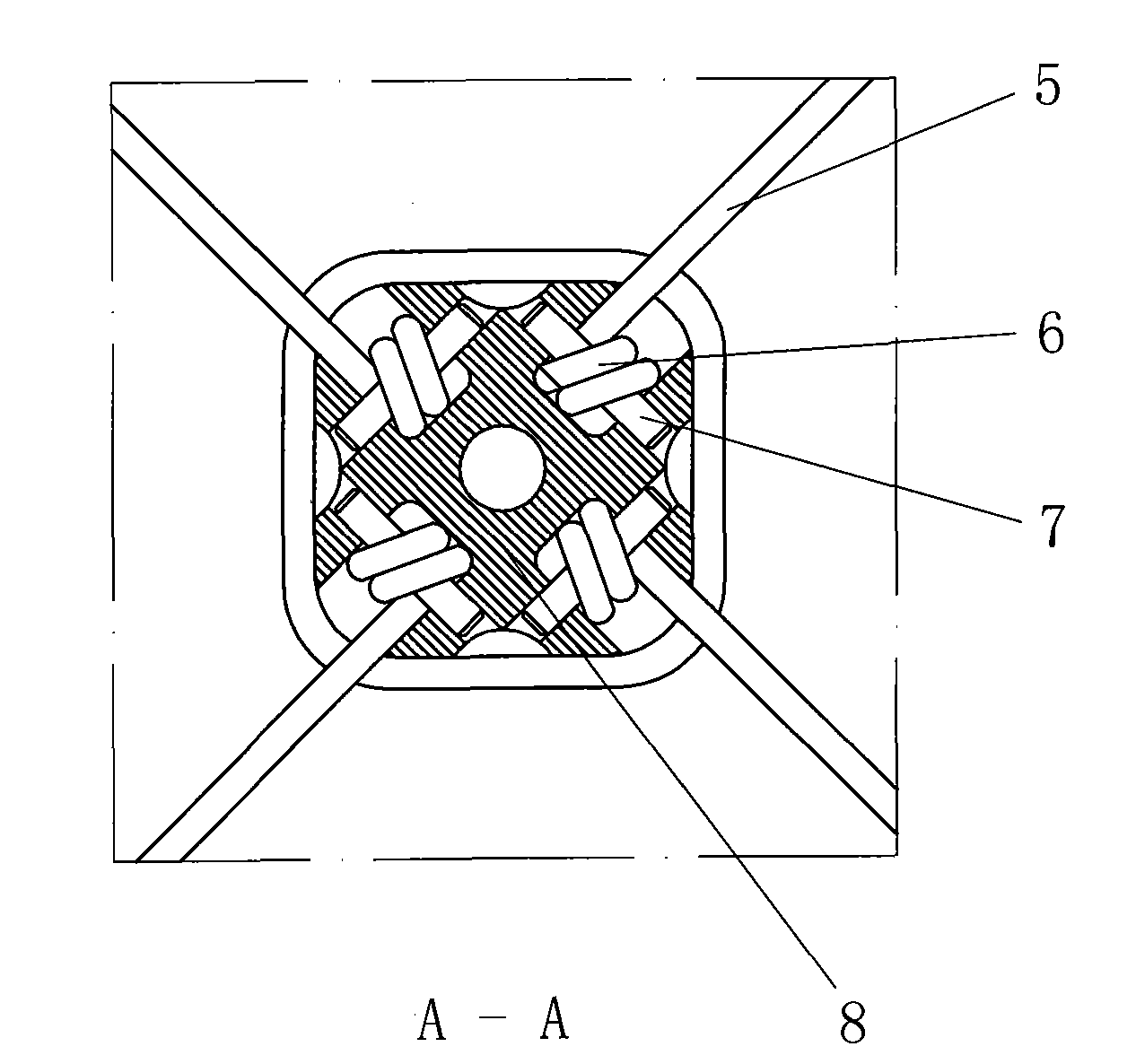

[0014] exist figure 1 , image 3 , Figure 5 Among them, the midpoint of the umbrella surface 1 is connected with the top end of the piston 8, the support bar 5 is connected on the diagonal line of the umbrella surface 1, and the rear end of the support bar 5 is set as a torsion spring 6, and the torsion spring 6 is connected to the piston through the small shaft 7. The upper end of the piston 8 is connected, and a transverse pin 15 is arranged in the inner hole of the piston 8 . The umbrella rod 2 is a hollow structure, and a spring seat 18 is connected to the lower end of the umbrella rod 2. The lower end of the umbrella rod 2 and the spring seat 18 are inserted into the umbrella handle 3 together. The piston 8 is arranged in the umbrella rod 2 , and an umbrella spring 17 is arranged between the piston 8 and the spring seat 18 .

[0015] exist Figure 4 , Image 6 Among them, the hollow shaft 10 traverses the umbrella handle 3, the rear end of the hollow shaft 10 is hin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap