Water window assembly structure of electric kettle

An electric kettle and a technology for assembling structures, which are applied to water-boiling utensils, kitchen utensils, household utensils, etc., can solve the problems of complex structure and many processes, and achieve the effects of reducing production processes, prolonging service life, and avoiding leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

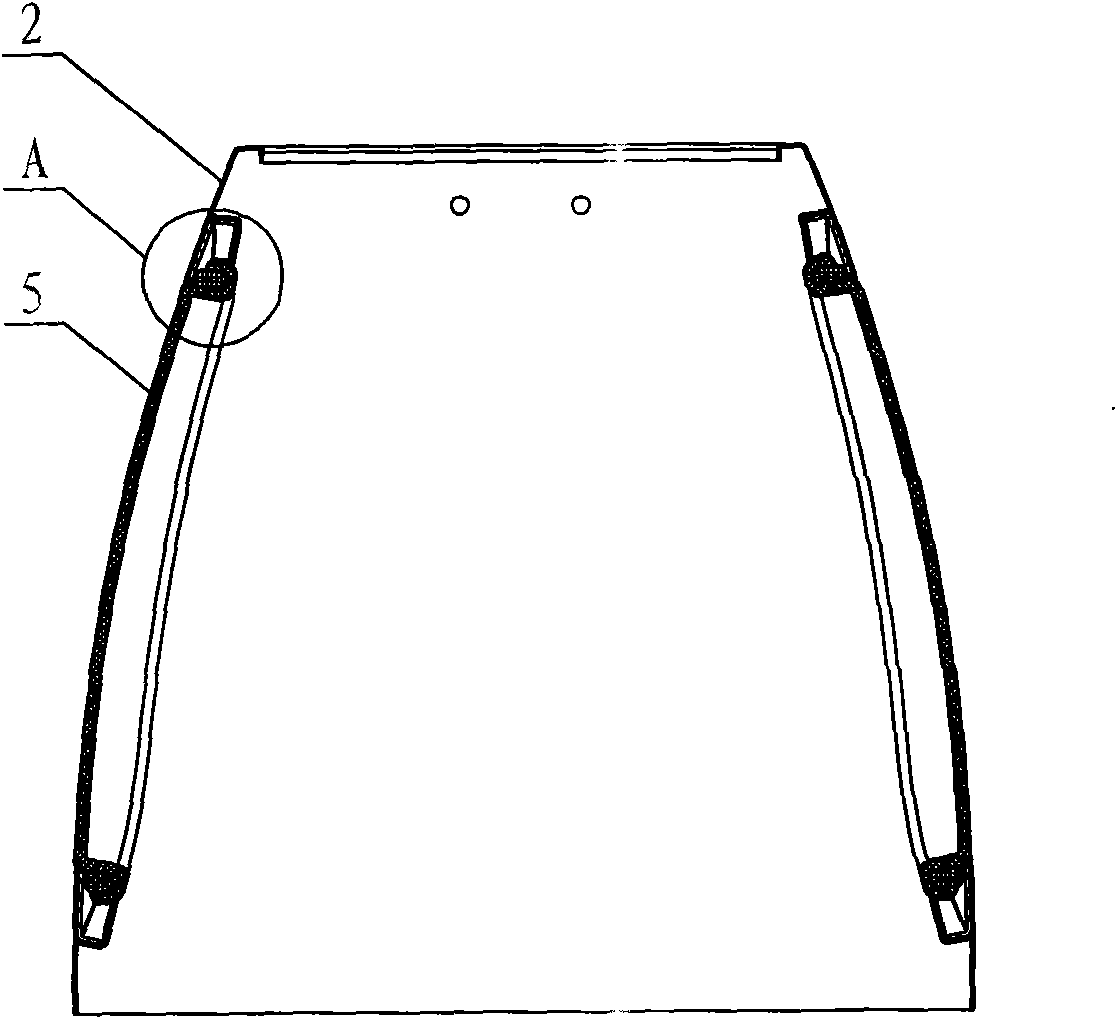

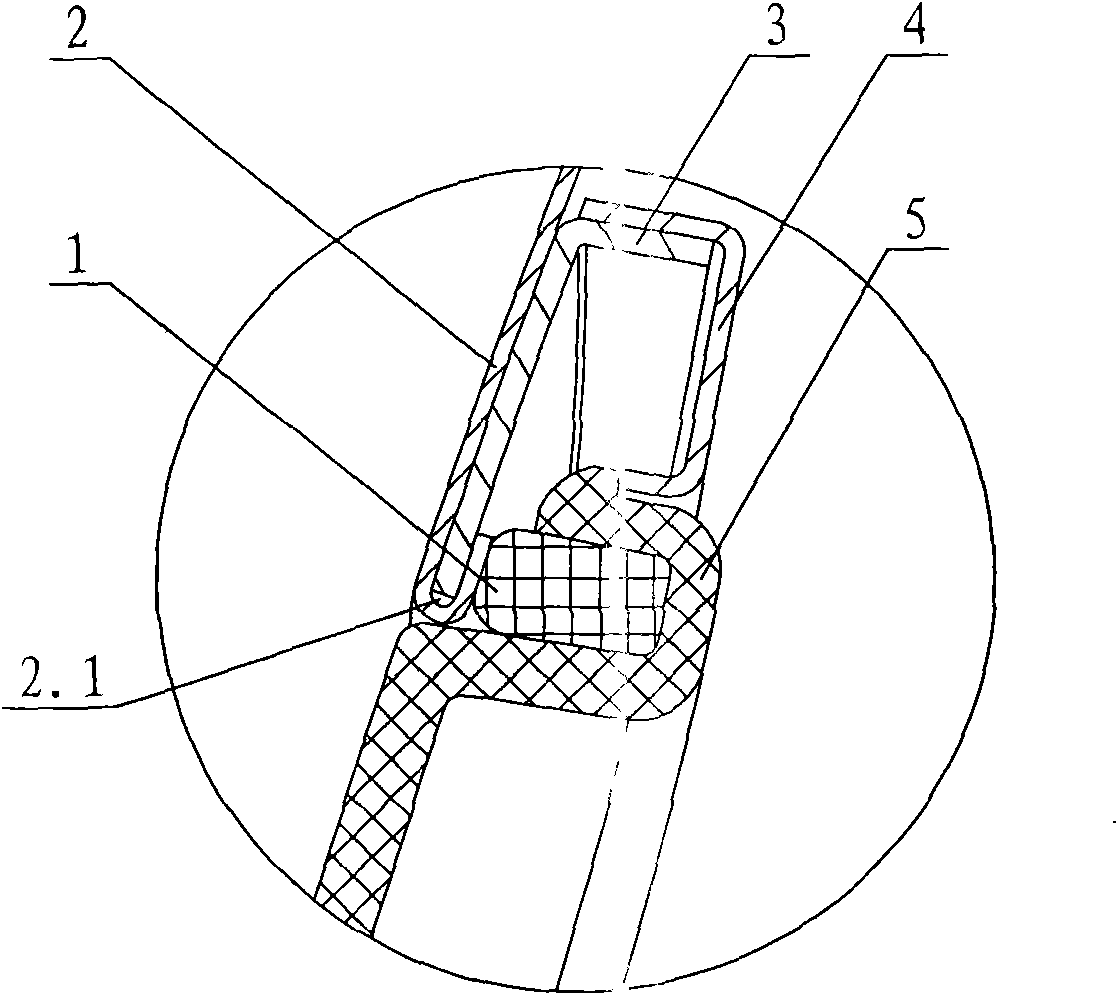

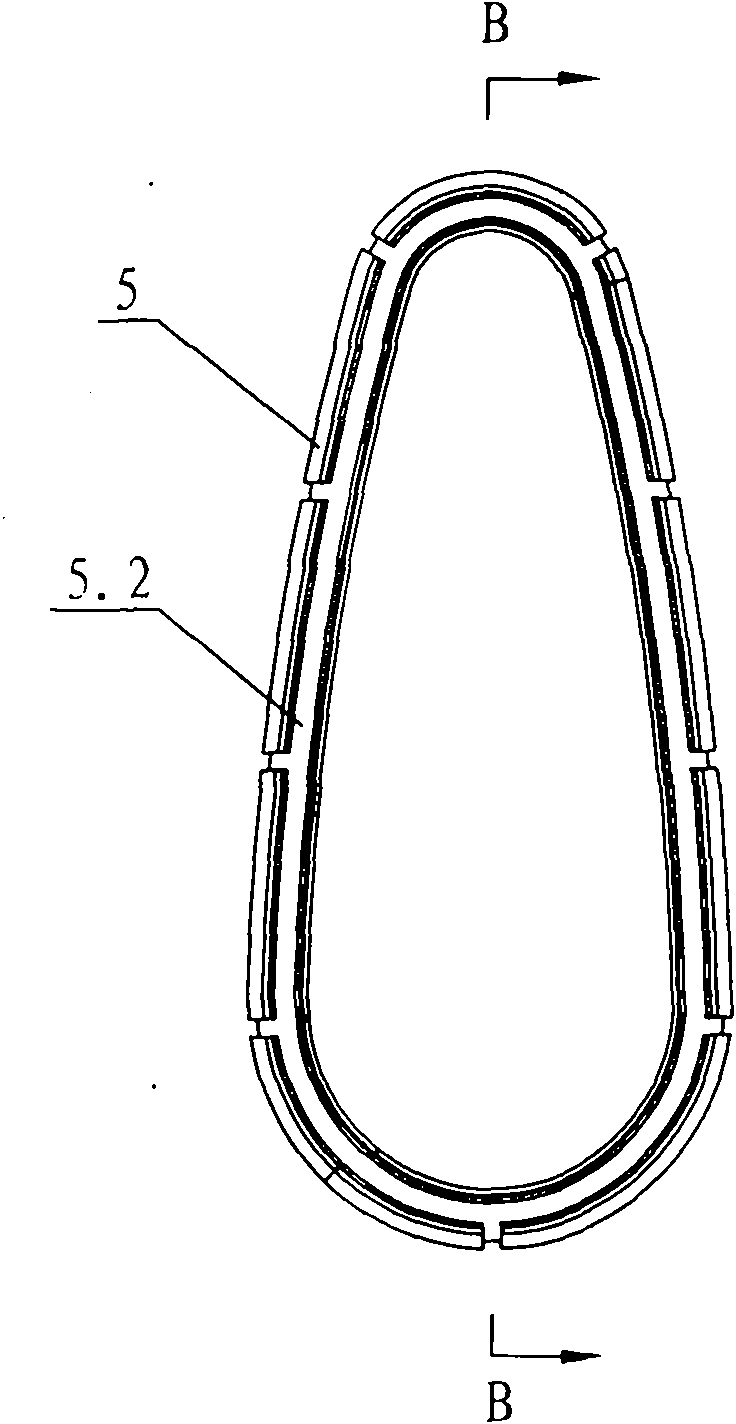

[0022] see Figure 1-Figure 10 , the water window assembly structure of the electric kettle includes a metal pot body 2 with a window, a water window 5 arranged on the window, a sealing ring 1 and a metal fixing frame, and the edge of the window of the metal pot body 2 is turned inward to form a Annular positioning hook groove 2.1, the metal fixing frame is an inverted L-shaped metal fixing frame I3 and a C-shaped metal fixing frame I I 4, the two parts are welded into a whole unsealed P-shaped part, the lower part is embedded in the positioning hook groove, and the middle part is not sealed The place is tightly fastened with the water window 5 outer edges. The edge of the water window 5 is provided with an annular groove 5.2 and an undercut 5.1, which are fastened with the metal fixing frame II 4. A sealing ring 1 is arranged in the annular groove 5.2, and the water window assembly equipped with the sealing ring 1 is removed from the metal pot 2 is forcibly pressed in by a s...

no. 2 example

[0024] The metal fixing frame is formed into an integral unsealed P-shaped part through one-time forming. Its undescribed part is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com