High flow piezoelectric pump

A piezoelectric pump, piezoelectric material technology, applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machines, etc., can solve problems such as the inability to provide high fluid flow in the hydraulic control system of the transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description is merely exemplary in nature and is not intended to limit the application, application or use.

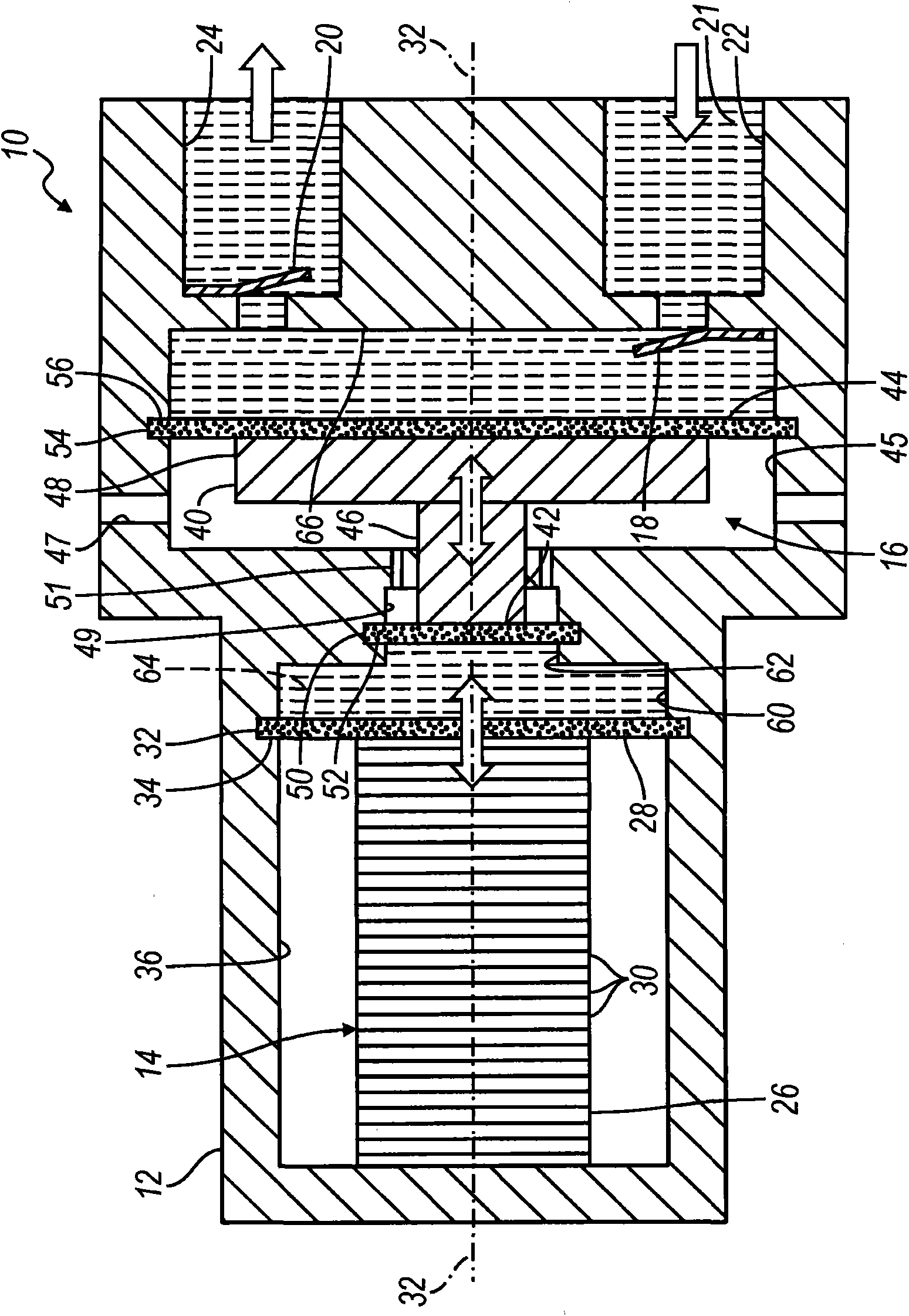

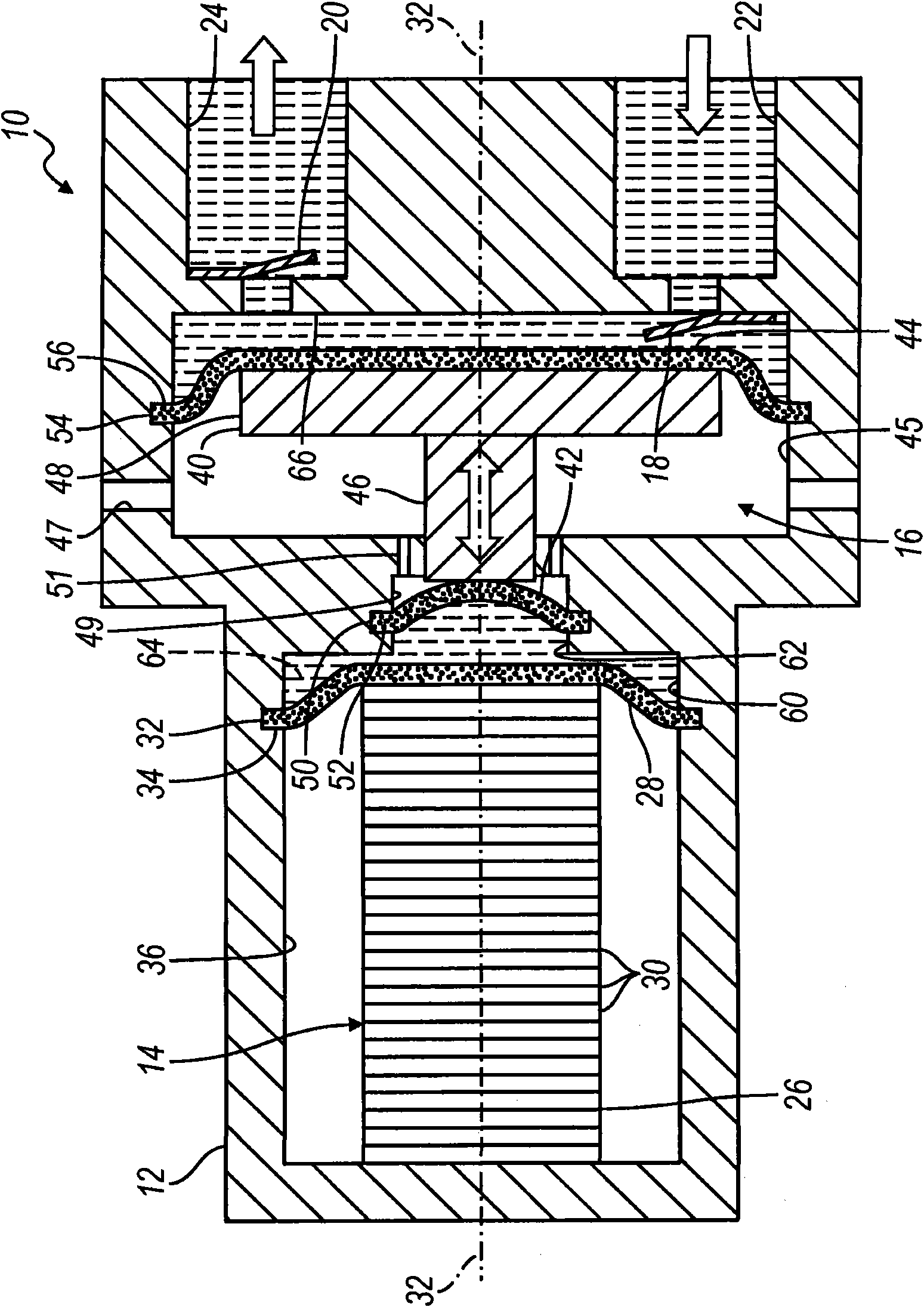

[0019] Referring to FIG. 1 , a piezoelectric pump in accordance with the principles of the present invention is generally indicated by the reference numeral 10 . The pump 10 generally includes a pump housing 12 , an actuator assembly 14 , a piston assembly 16 , an inlet valve 18 and an outlet valve 20 . As will be described in detail below, the pump 10 is operable to pump a substance, such as hydraulic fluid 21 , through an inlet 22 in the housing 12 to an outlet 24 in the housing 12 .

[0020] The actuator assembly 14 is located within the housing 12 and includes an actuator stack 26 in at least partial contact with a first diaphragm 28 . The actuator stack 26 is composed of a plurality of stacked layers 30 of piezoelectric material. Layer 30 of piezoelectric material is comprised of a piezoelectric material operable to expand and contract (ie, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com