Water receiving device for measuring hole of upper and lower surface detection instruments

The technology of a surface detector and a water receiving device is applied in the field of machinery, which can solve the problems of heavy maintenance workload, unsafe slipping and falling, facilities that do not consider drainage, etc., and achieves the effect of improving cleanliness and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

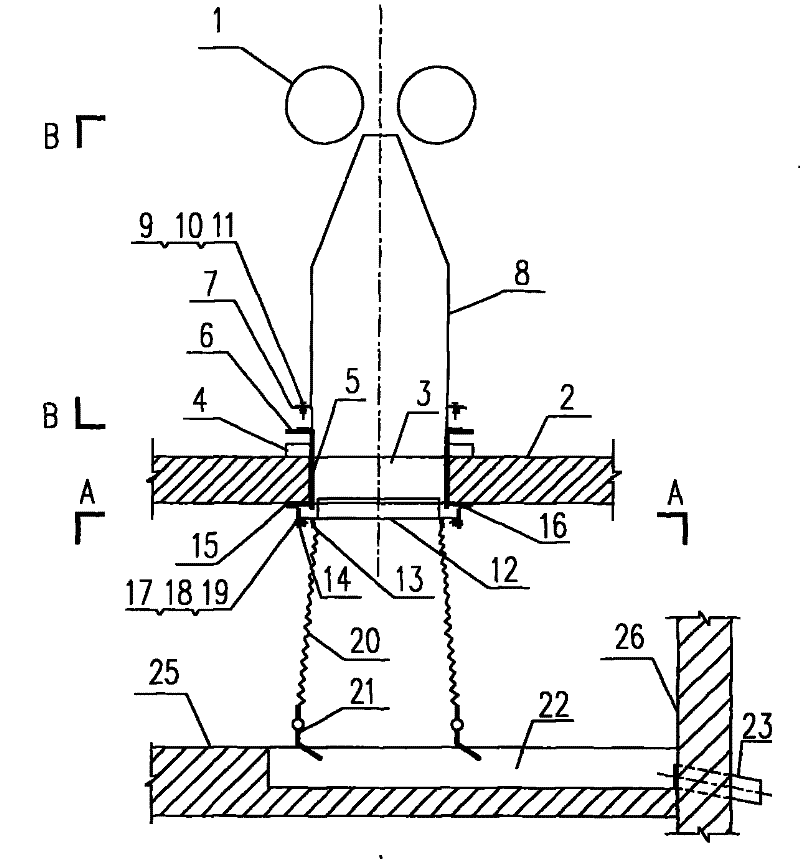

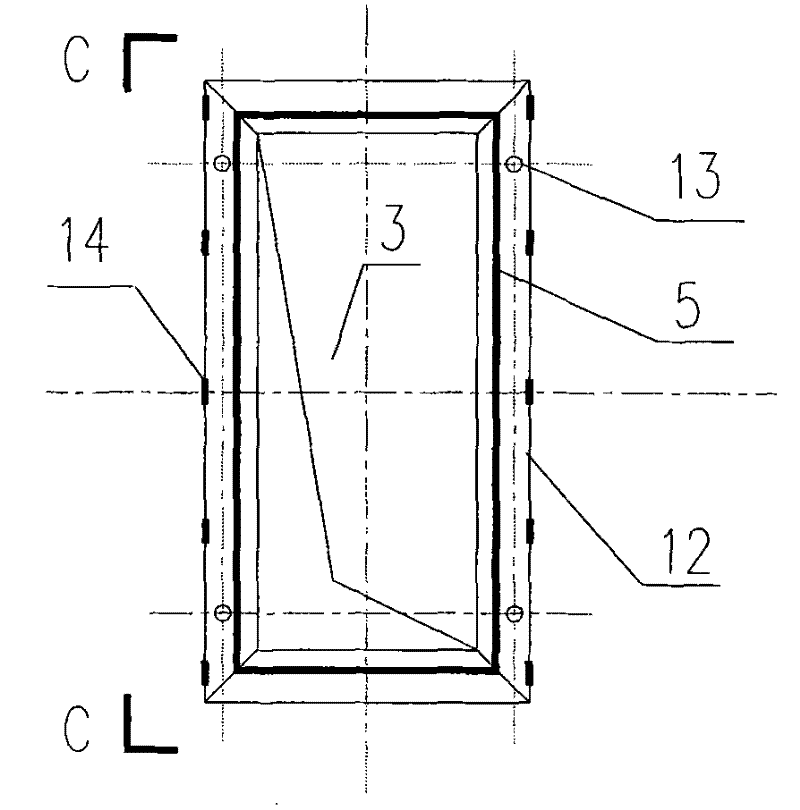

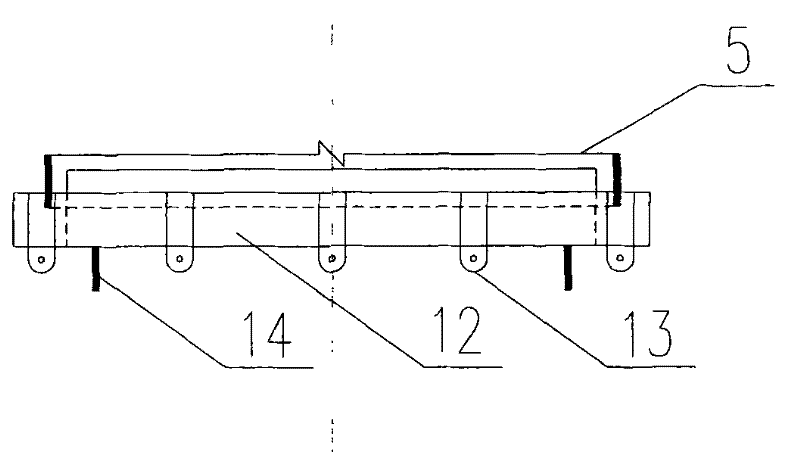

[0014] The present invention will be further described in conjunction with accompanying drawing:

[0015] Such as Figure 1~3 As shown, the roof 2 of the small room under the roller table 1 has a measuring hole 3, and a steel plate 5 is embedded in the four walls of the measuring hole 3, and the lower side of the steel plate 5 is 15-70mm lower than the roof 2 as a drip plate; Above the roof 2 surface waterproof ring 4, as the first waterproof ring, prevent the water on the roof 2 surface from entering the measurement hole 3; design the concrete waterproof ring 4 around the outer wall of the upper surface steel plate 5 of the measurement hole 3 as a protective For the second waterproof ring, the steel plate 5 is about 100-120 mm higher than the surface of the waterproof ring 4; a steel plate 6 with bolt holes is welded on the upper surface of the steel plate 5, a channel steel 7 is welded on the upper surface of the steel plate 6, and the steel plate 6 or the channel steel Fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com