Modular sliding device and use method thereof

A sliding device, module technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of low load capacity, large vibration and noise, achieve high load capacity, improve load capacity, straightening and trimming Simple effects with matching surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

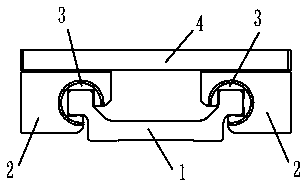

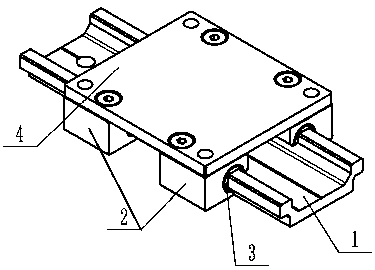

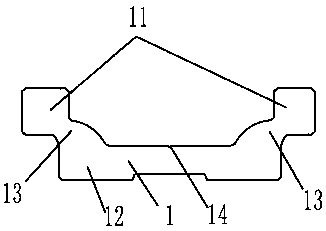

[0058] Such as Figure 1-7 As shown, the module sliding device includes a guide rail 1 with a rail 11, and a slider 2 installed on the rail 11, the contact surface of the slider 2 and the rail 11 is provided with a slide plate 3 for reducing friction, in:

[0059] The slider 2 is provided with a chute 21, and the slider 3 is installed in the chute 21. The slider 2 is also provided with a mounting structure for assembling the load bearing member 4, and the load bearing member 4 is used for to carry the load;

[0060] The guide rail 1 includes a base 12 for being installed on a support platform, and the rail 11 is extendedly connected to the base 12, so that the rail 11 is located outside the width range of the base 12, and the base 12 and The rails 11 extend in the same direction, and both have the same extension length.

[0061] The extension of the track 11 is connected to the base 12, which means that after the track 11 is connected to the base 12, the track 11 is outside...

Embodiment 2

[0073] Such as Figure 1-7 As shown, the method of using the module sliding device, when using the module sliding device as in Example 1, proceed according to the following steps:

[0074] a. Install the slider 3, install the slider 3 into the chute 21 of the slider 2, and keep the slider 3 and the slider 2 relatively fixed;

[0075] b. Install the slider 2, assemble the guide rail 1 and the slider 2, and make the track 11 of the guide rail 1 pass through the chute 21;

[0076] c. Fix the guide rail 1, and fix the guide rail 1 on the support platform through the installation hole 23 provided on the base 12 of the guide rail 1;

[0077] d. Install the load bearing member 4 and assemble the load bearing member 4 on the slider 2 .

[0078] The slider 3 is embedded and installed between the guide rail 1 and the slider 2, so that the slider 3 and the slider 2 form an assembled overall structure, and relying on the support of the slider 3, the slider 2 is smoothly on the guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com