Integrated prefabricated underground water intake pumping station

A water pumping station and underground technology, applied in the field of integrated prefabricated buried water intake pumping station, can solve the problems of potential safety hazards, increase the bearing capacity of the pumping station, small scope, etc. Compression, the effect of short axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

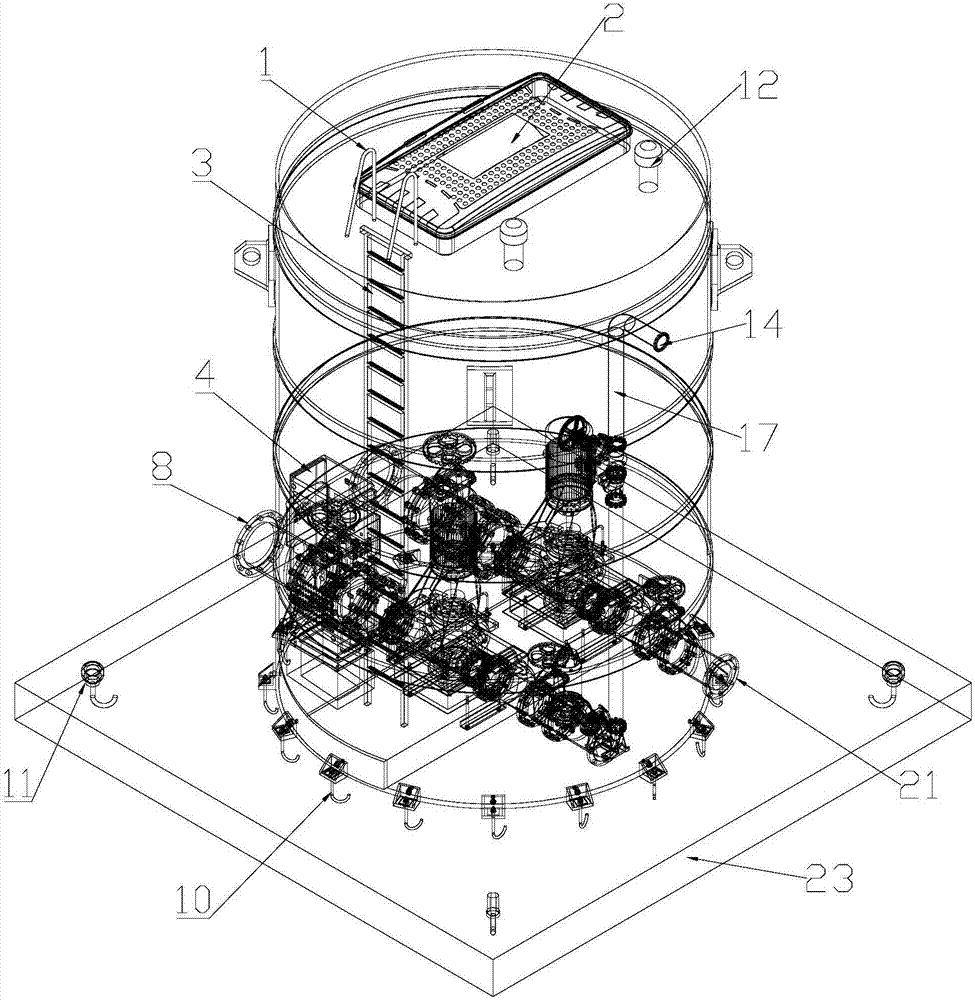

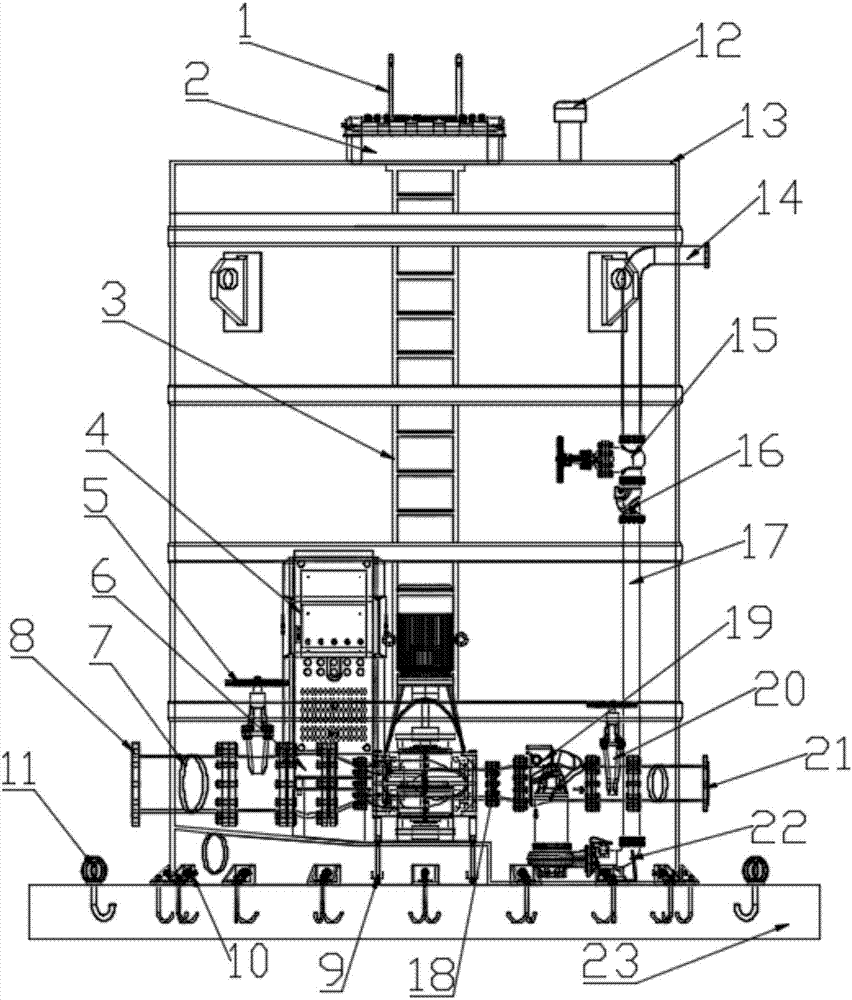

[0015] see Figure 1-2 , an integrated prefabricated buried water intake pump station, including a cylinder cover 13, a cylinder body, an electric control cabinet 4, a pressure pipeline 17, a submersible sewage pump 22, a pipeline pump and a foundation 23, and the cylinder cover 13 is located at the bottom of the cylinder body The top and the cover 13 are provided with an inspection port 2 and a vent pipe 12, the upper end of the inspection port 2 is provided with a handrail 1, a ladder 3 is installed inside the cylinder and one end of the ladder 3 is connected to the inspection port 2, and the bottom of the cylinder is fixed on the foundation The upper part of 23 is fixed with a triangle iron 10, the other end of the ladder 3 is connected to the bottom of the cylinder, the outside of the cylinder is provided with a water inlet pipe 8 and an outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com