Electrical control drive device for hydraulic valve core

A driving device and hydraulic valve technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of difficult to achieve precise control, limitation of driving force of electromagnet drive device, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

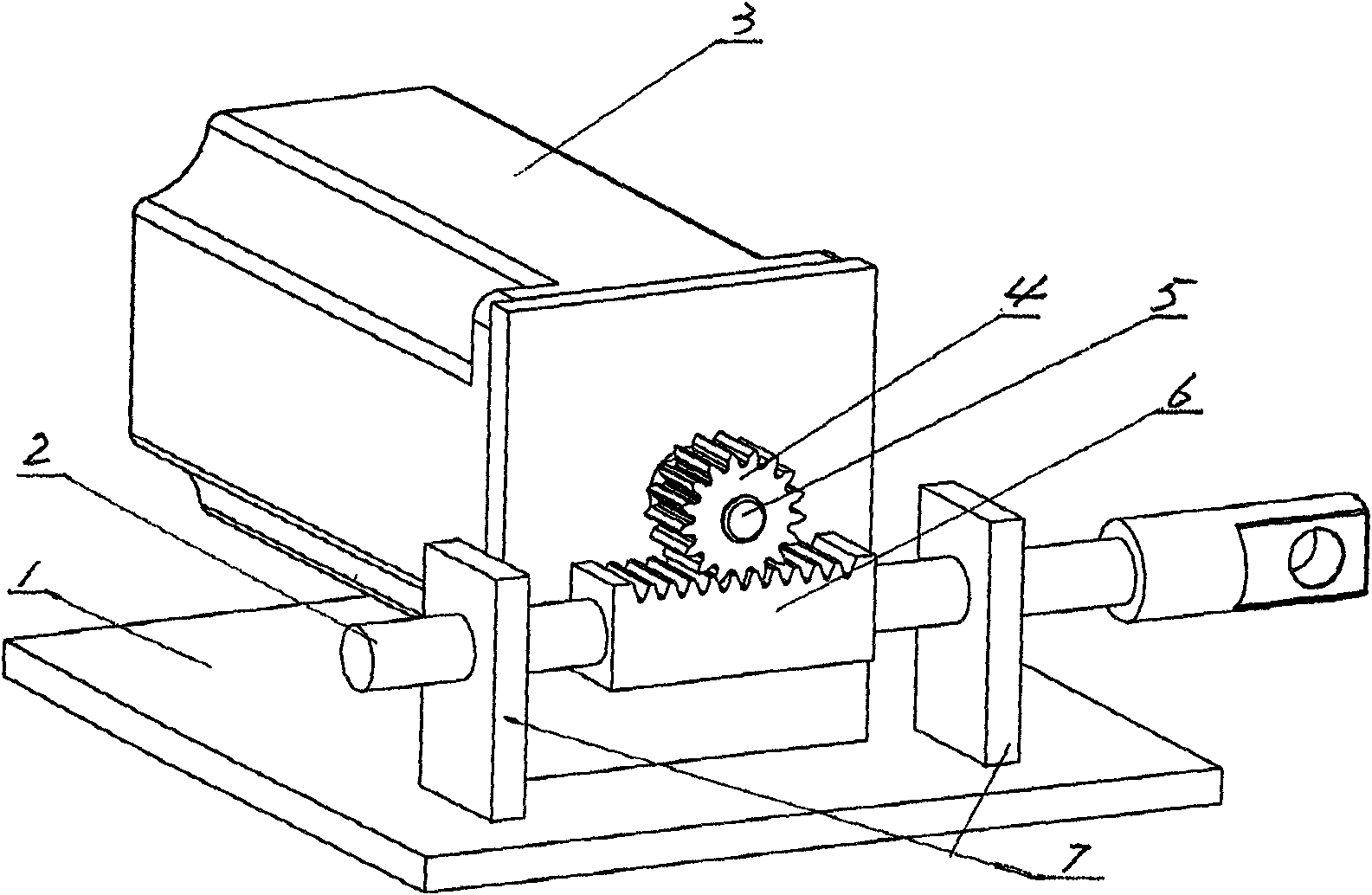

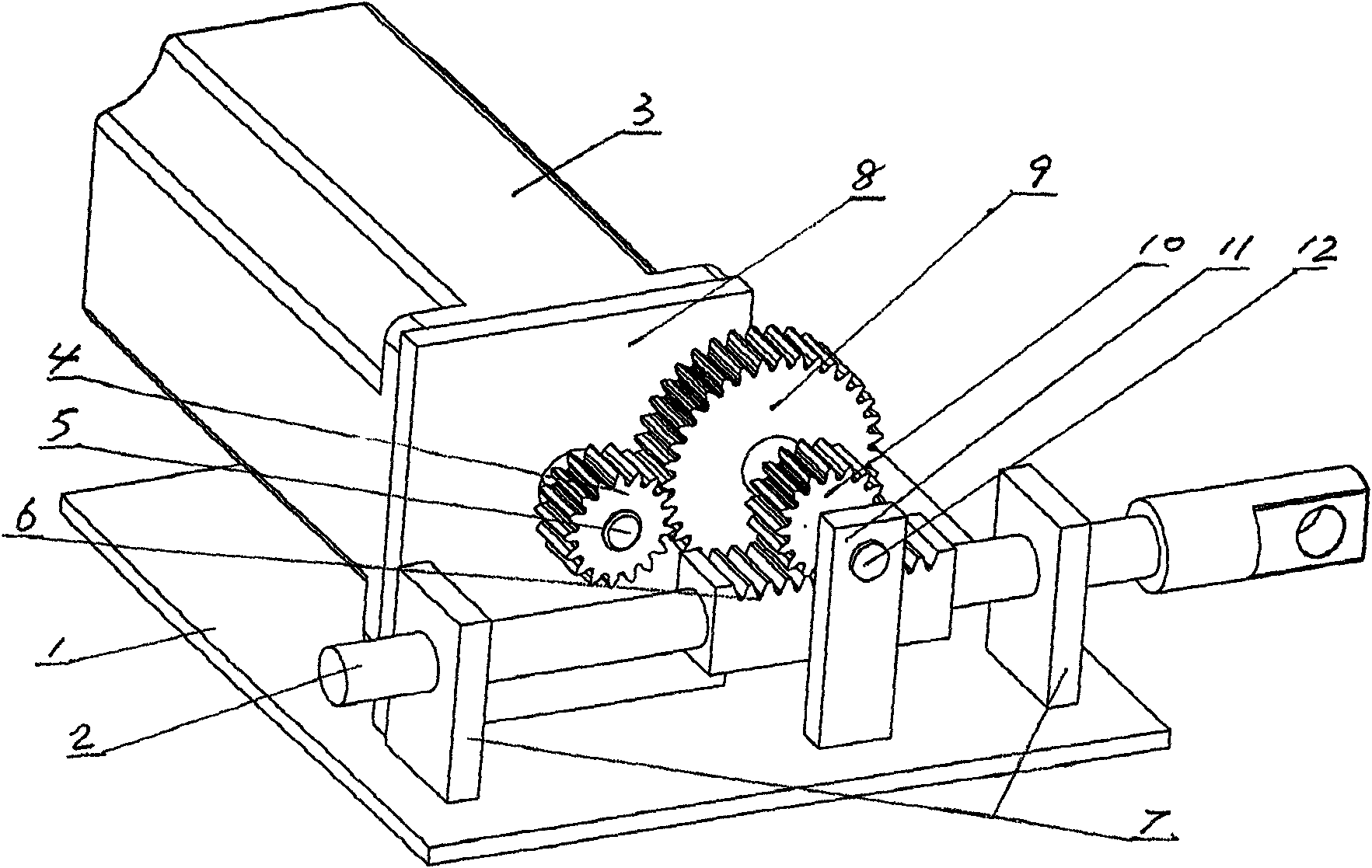

[0012] Such as figure 1 As shown, the electronically controlled driving device for the hydraulic spool of the present invention includes a base 1, which is flat and can be the shell of a machine or a vehicle in use, or the table top of an experimental platform. The base 1 is provided with a guide rod 2 and two support seats 7 . Both supporting bases 7 are flat plates, they are vertically arranged facing each other, and their lower sides are fixed on the base 1 . Concentric holes are processed on the two support bases 7, and both ends of the guide rod 2 slide through the concentric holes on the two support bases 7 and then protrude outside. connected. A motor 3 is arranged on the base 1 on one side of the guide rod 2, the motor is fixed on the base 1, a gear 4 is fixed on the output shaft 5 of the motor 3, and a rack 6 is fixed on the guide rod 2, and the gear and the rack Mesh together. When working, the gear 4 on the output shaft 5 is driven by the motor 3 to rotate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com