Backlight module

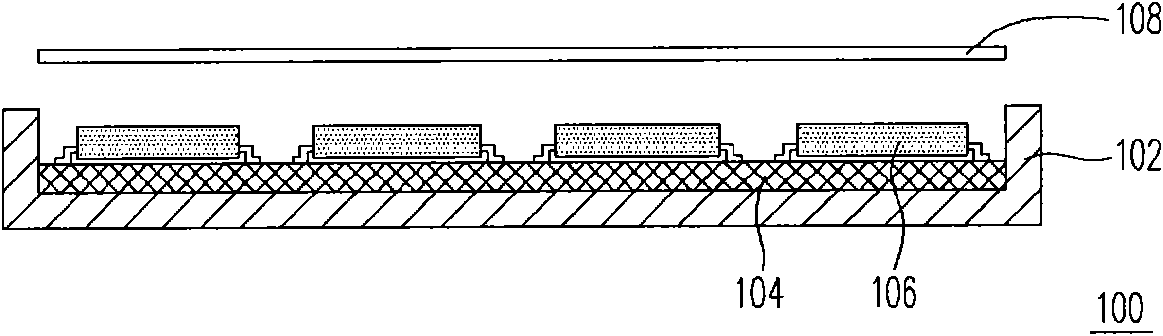

A backlight module and light technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of damage, difficult conduction of heat energy of light-emitting diodes, shortened life of light-emitting diodes 106, etc., and achieve the effect of reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

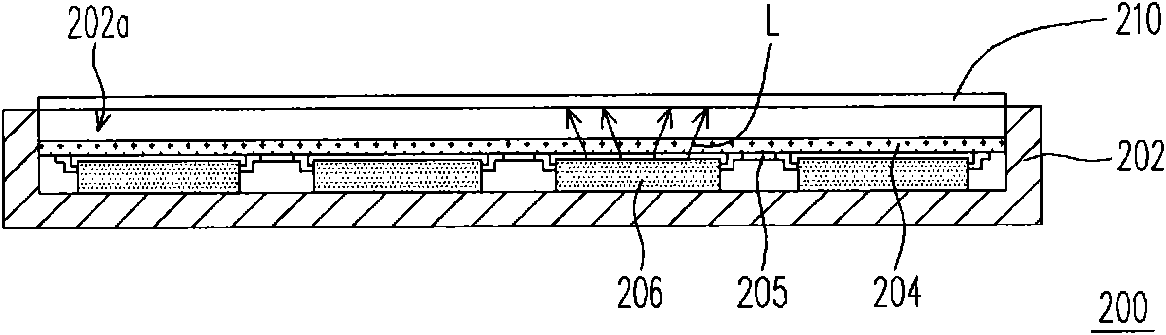

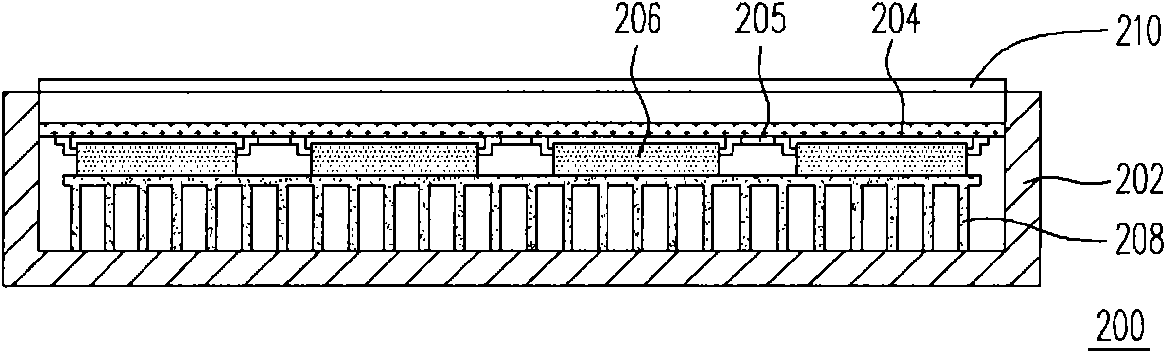

[0035] figure 2 It is a schematic cross-sectional view of a backlight module according to an embodiment of the present invention. Please refer to figure 2 , the backlight module 200 of the present invention includes a light box 202 , a transparent substrate 204 and a plurality of light emitting units 206 . Wherein, the light box 202 has an opening 202a. The light emitting unit 206 is disposed on the transparent substrate 204 and located in the light box 202 . In one embodiment, there is a circuit pattern 205 on the transparent substrate 204 . The light emitting units 206 can be electrically connected to each other through the circuit pattern 205 , or can be electrically connected to an external control circuit (not shown) through the circuit pattern 205 . Specifically, the light emitting unit 206 may be a light emitting diode. Depend on figure 2 It can be seen that the light L emitted by the light emitting unit 206 passes through the transparent substrate 204 and exit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com