Lifting device of engineering machine and telescopic type belt delivery wagon with same

A lifting device and engineering machinery technology, applied in the direction of conveyors, motor vehicles, conveyor objects, etc., can solve problems such as the inability to meet actual needs, and achieve the effect of simple and compact lifting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

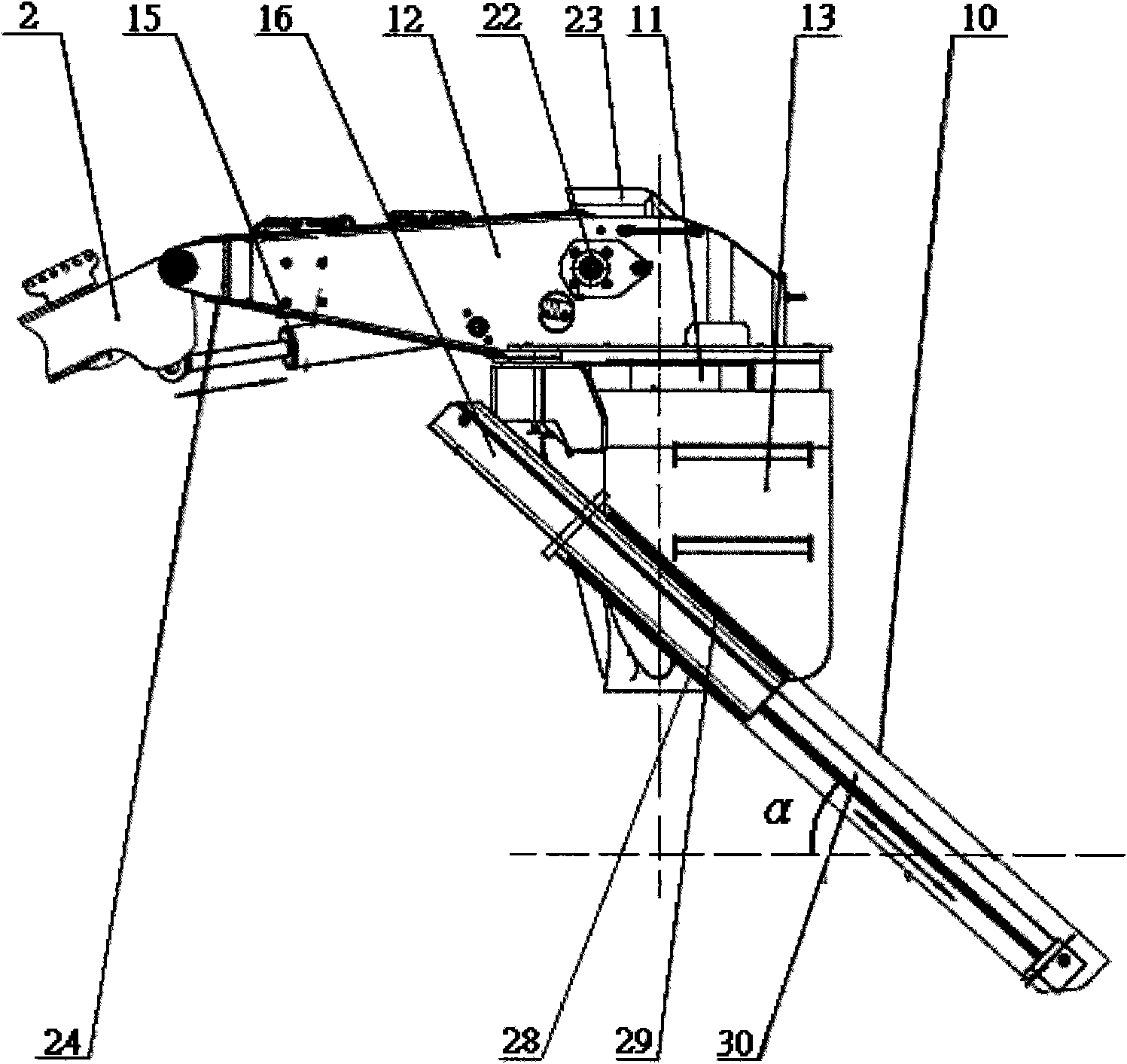

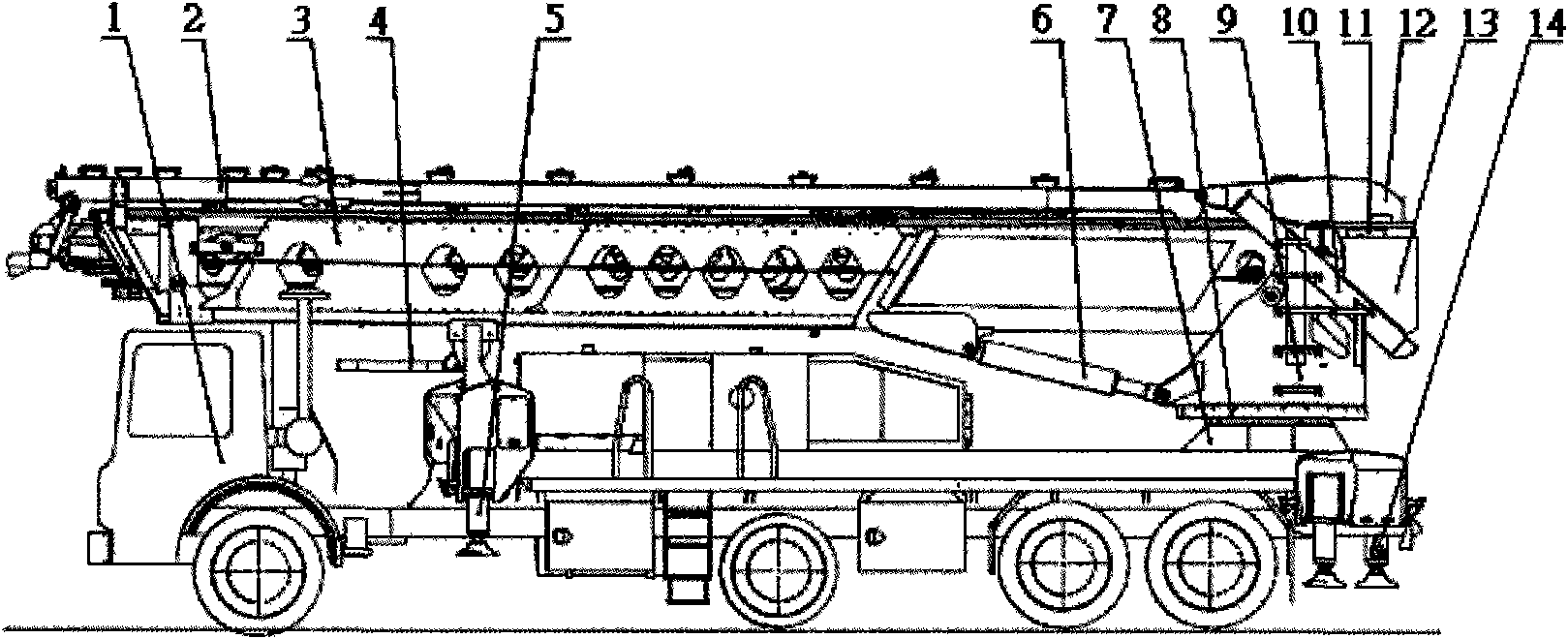

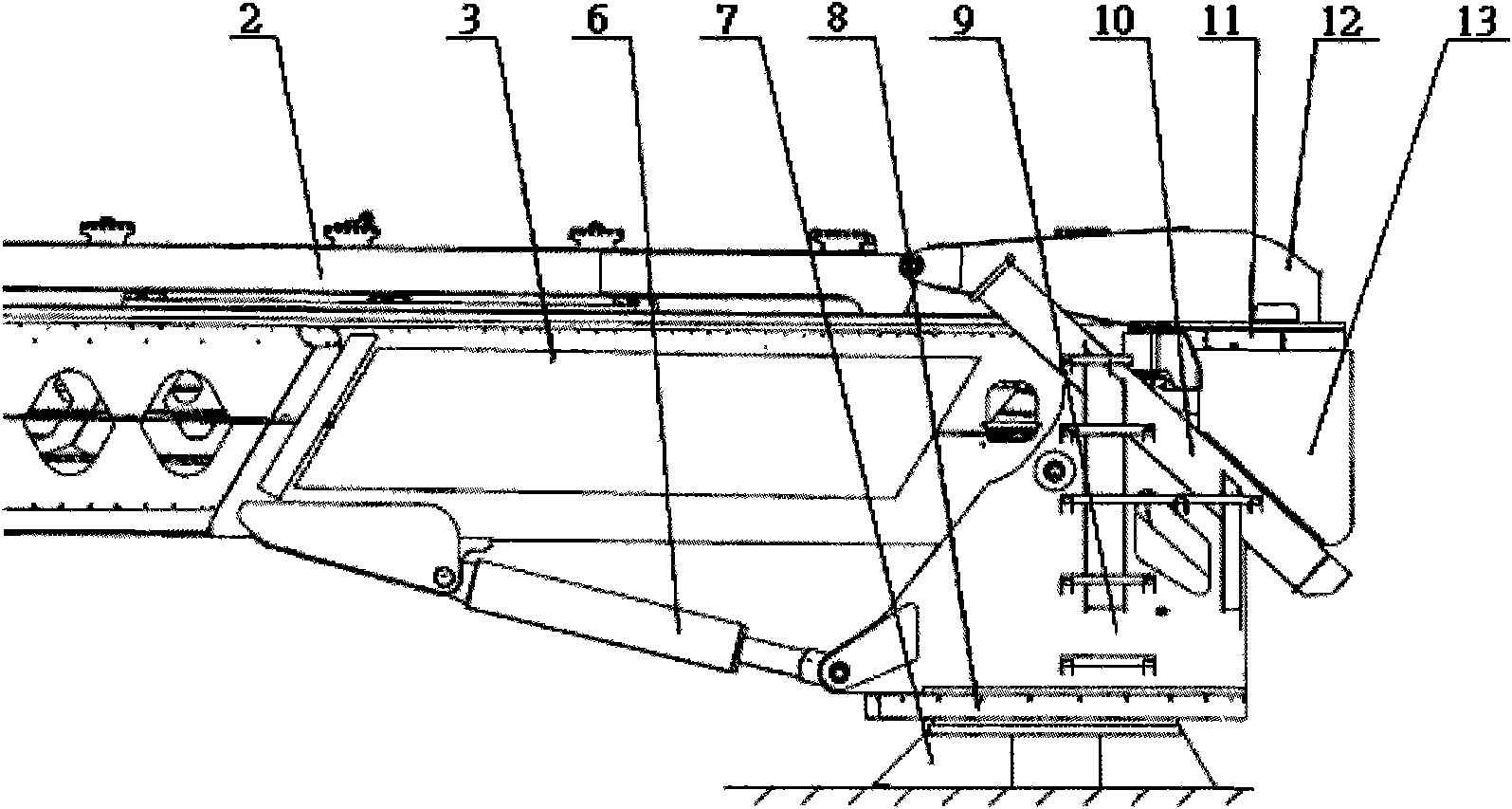

[0017] Such as figure 1 As shown, it is a structural schematic diagram of a lifting device of a construction machine provided by the present invention, which includes a rotary head 12 of the discharge device with a rotary device 11 at the bottom, and a rotary head 12 on both sides of the rotary head 12 of the discharge device. Rotary head welding frame 24, the discharge end of the feeding belt conveyor 2 is fixed to the cantilever end of the rotary head welding frame 24 with a rotating shaft, and idlers, drive motors 22, and discharge sleeves 23 are installed on the welding frame 24 , Blanking hopper, driving drum, etc. The cylinder body end of feeder lifting oil cylinder 15 is fixed on the symmetrical centerline position of rotary head welding frame 24 with rotating shaft, and the piston rod end is then fixed on the discharge end symmetrical centerline position of feeder 2 with rotating shaft.

[0018] The present invention enlarges and strengthens the original slewing head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com